Grain processing stone-removing machine

A stone removal machine and grain technology, applied in the direction of solid separation, dust removal, grading, etc., can solve the problems of complicated operation and slow speed, and achieve the effect of convenient operation, convenient cleaning, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

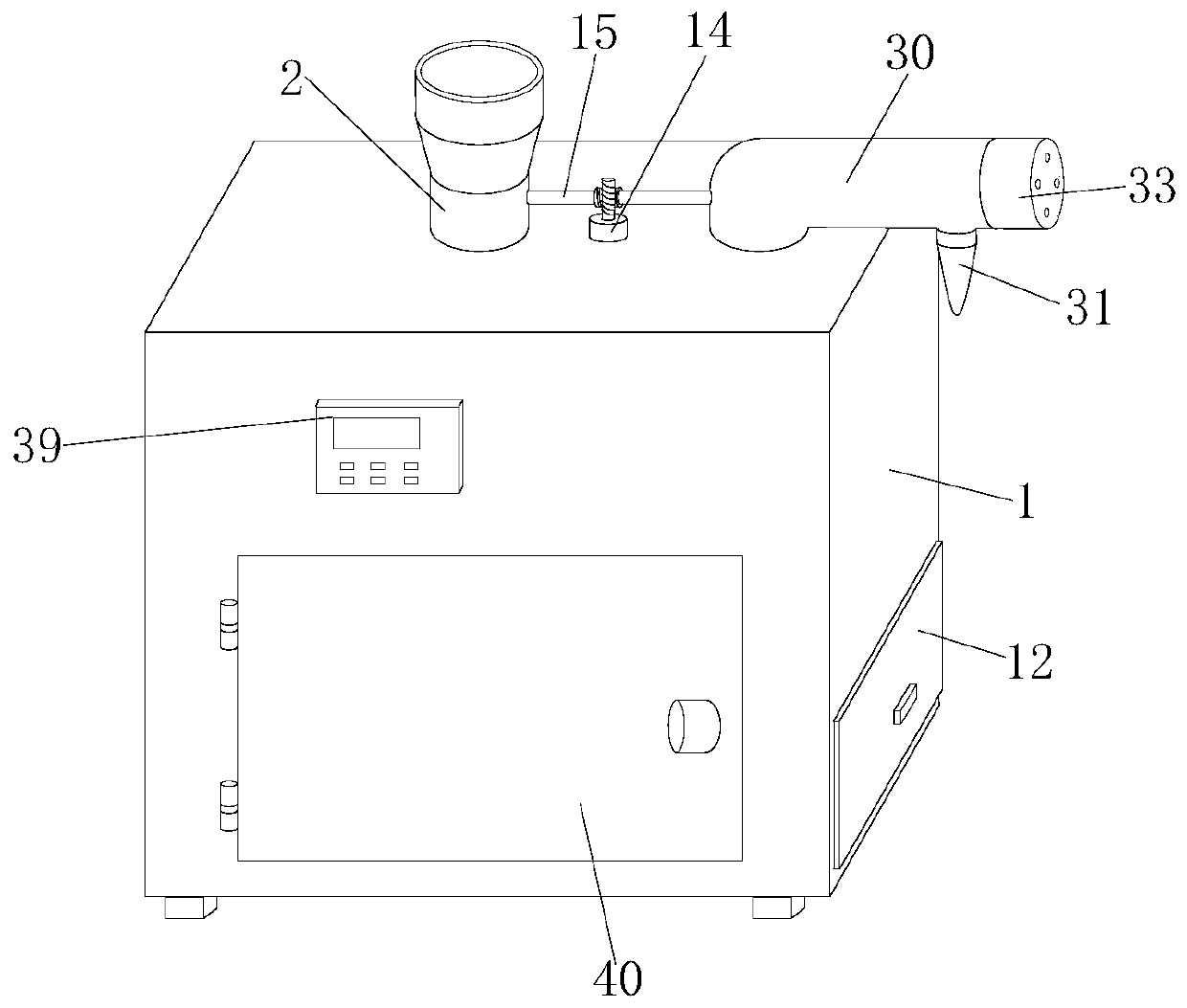

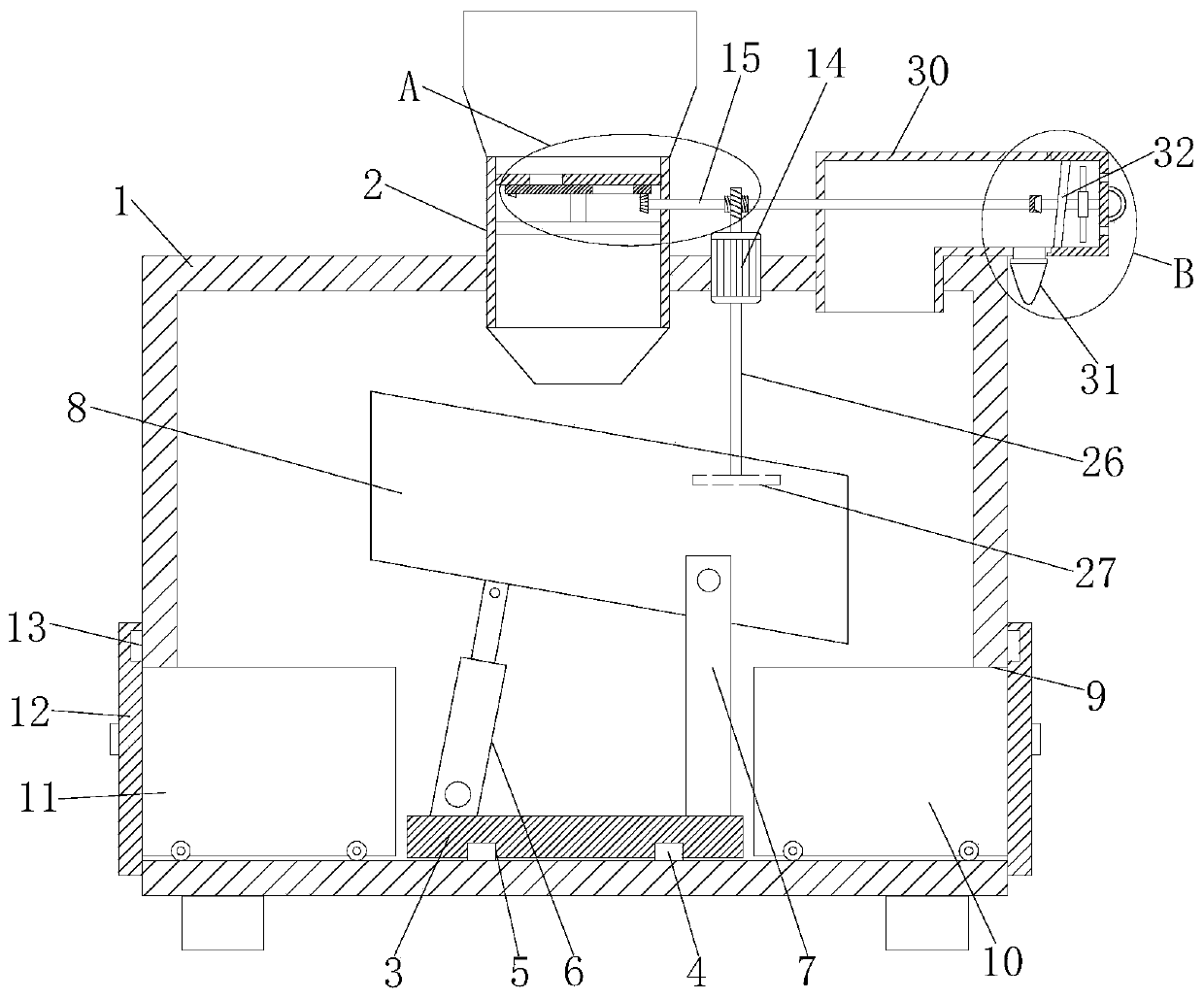

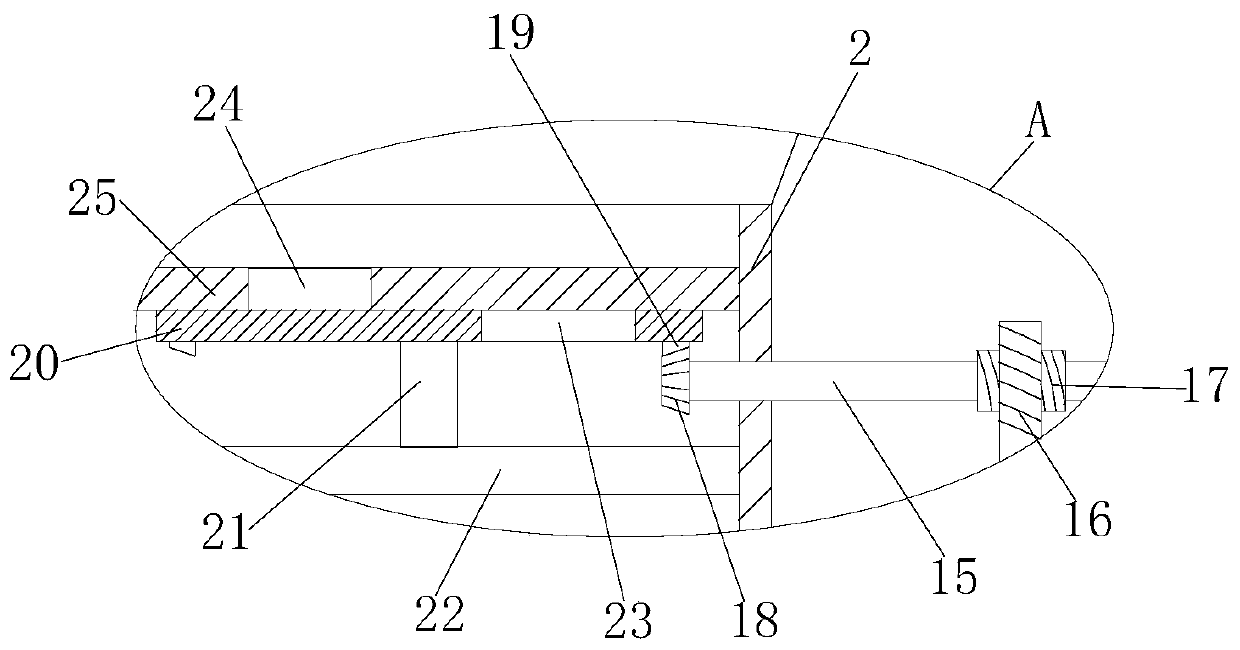

[0031] refer to Figure 1-5 , a grain processing destoner, comprising a processing box 1, a feeding cylinder 2 is embedded in the top of the processing box 1, an inclined plate 8 is slidably installed in the processing box 1, the feeding cylinder 2 is matched with the inclined plate 8, and the processing box Both sides of 1 are provided with through holes 9, and rice collection vehicles 10 and stone collection vehicles 11 are movably connected in the two through holes 9, and both sides of the inclined plate 8 are respectively suitable for rice collection vehicles 10 and stone collection vehicles 11 The top of the processing box 1 is embedded with a double-head motor 14, and the bottom output shaft of the double-head motor 14 is fixedly equipped with a driving structure, which is compatible with the inclined plate 8. On the top output shaft of the double-head motor 14 A worm 16 is fixedly installed, and the top of the processing box 1 is rotatably connected with a horizontal sh...

Embodiment 2

[0042] refer to Figure 1-5 , a grain processing destoner, comprising a processing box 1, a feeding cylinder 2 is embedded in the top of the processing box 1, an inclined plate 8 is slidably installed in the processing box 1, the feeding cylinder 2 is matched with the inclined plate 8, and the processing box Both sides of 1 are provided with through holes 9, and rice collection vehicles 10 and stone collection vehicles 11 are movably connected in the two through holes 9, and both sides of the inclined plate 8 are respectively suitable for rice collection vehicles 10 and stone collection vehicles 11 The top of the processing box 1 is embedded with a double-head motor 14, and the bottom output shaft of the double-head motor 14 is fixedly installed with a push structure by welding. The push structure is compatible with the inclined plate 8, and the top of the double-head motor 14 outputs A worm 16 is fixedly installed on the shaft by welding. The top of the processing box 1 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com