Bamboo filament drawing machine

A technology of silk machine and bamboo, applied in mechanical equipment, sugarcane machining, wood processing equipment, etc., can solve problems such as difficulty in bamboo threading, and achieve the effect of great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

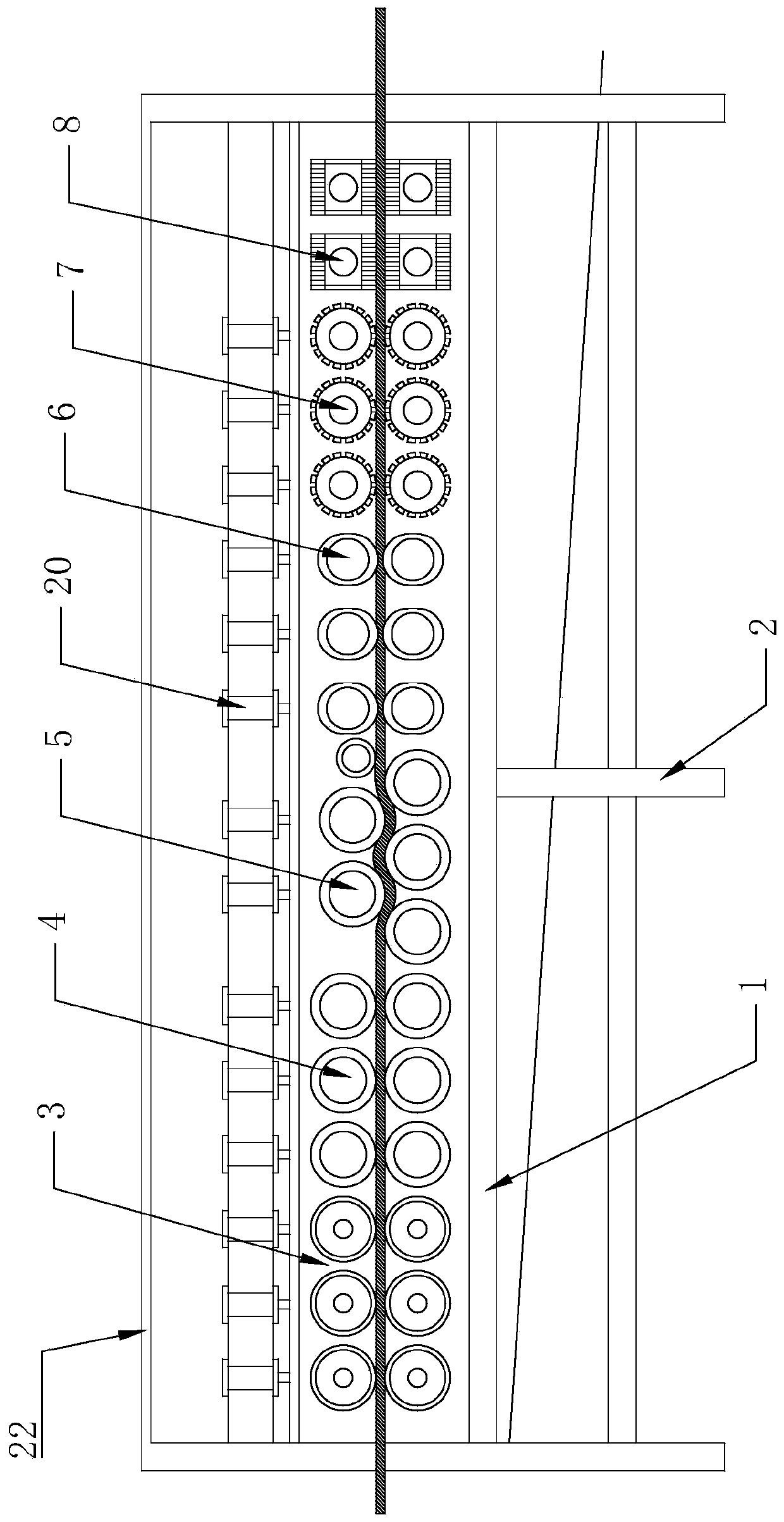

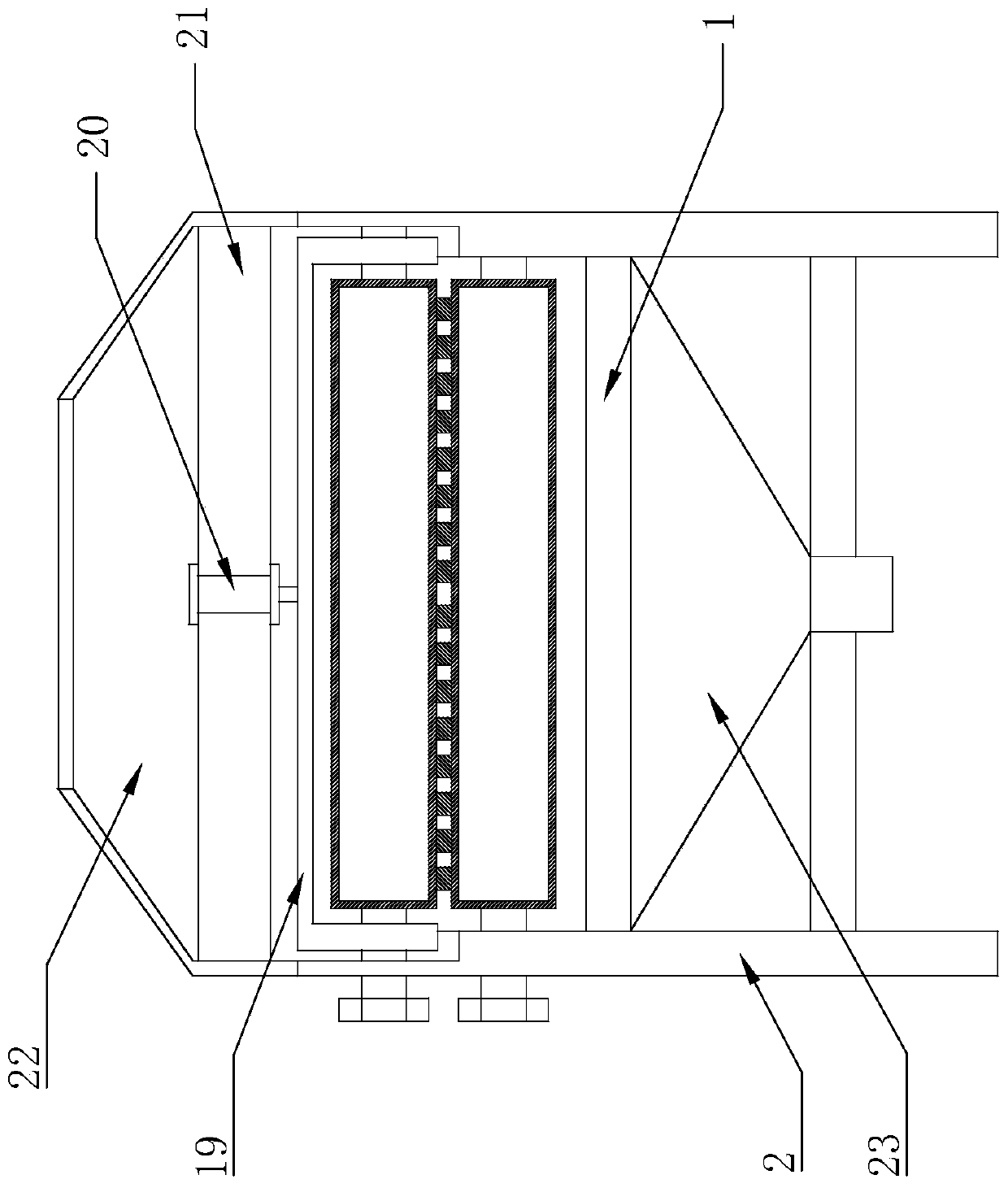

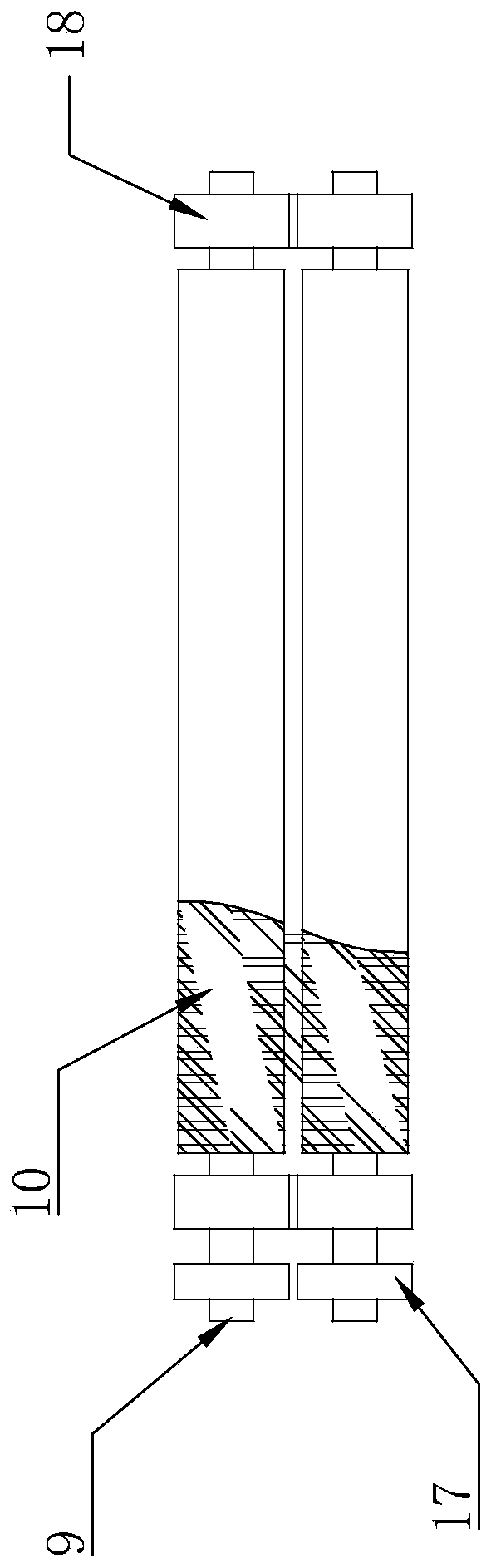

[0025] Such as Figure 1-14 As shown, a bamboo spinning machine includes a frame 1 and a leg 2 at the bottom of the frame 1, and the frame 1 is successively divided into a hemp roller rolling zone 3 and a skewed roller twisting zone from the feed end to the discharge end. 4. Bending, twisting and tearing zone 5, beating and stripping zone 6, bending and vibrating zone 7 and combing and threading zone 8, hemp roller rolling zone 3 is supported and fixed by the rotating shaft 9 with upper and lower layers of flower rollers that are symmetrical and rotate synchronously 10. The inclined roller twisting zone 4 supports and fixes the upper and lower layers of the inclined rollers 11 with inclined grooves arranged on the surface through the rotating shaft 9, and the bending and twisting area 5 supports and fixes the upper and lower layers of synchronously rotating toothed rollers 12 through the rotating shaft 9. And the upper and lower layers of toothed rollers 12 are staggered, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com