An injection molding process for preventing injection overflow

An injection molding process and overflow technology, which is applied in the field of injection molding process to prevent injection overflow, can solve the problems of the original properties of a single pellet, the inability to effectively adjust the melting speed and quantity, and single production materials, so as to improve the product Appearance, stabilize product appearance, ensure continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

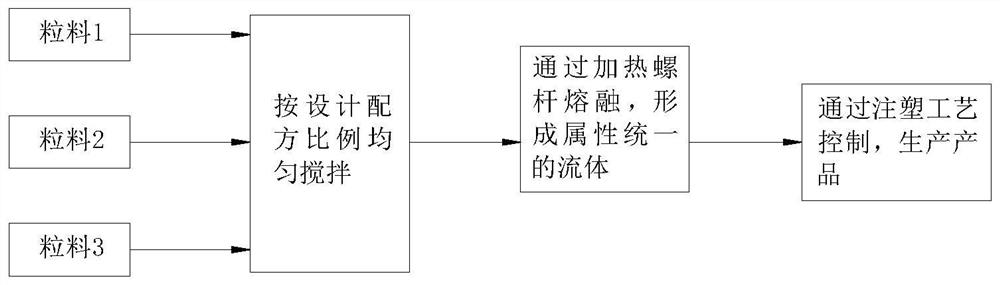

[0022] An injection molding process for preventing injection overflow, comprising the following steps:

[0023] (1) Preparation of modified polyethylene: 900 parts of low-density polyethylene, 99 parts of high-density polyethylene and 1 part of slippery agent were mixed and stirred for 10 minutes to obtain uniform blend pellets;

[0024] (2) Injection molding: Add the blend pellets in step (1) to the hopper of the injection molding machine, and the blend pellets are melted by the heating screw in the heating barrel to form a fluid with uniform properties, and inject it with a gate mold , holding pressure, cooling molding, demoulding, to obtain the product.

Embodiment 2

[0026] An injection molding process for preventing injection overflow, comprising the following steps:

[0027] (1) Preparation of modified polyethylene: 950 parts of low-density polyethylene, 49 parts of high-density polyethylene and 1 part of slippery agent were mixed, stirred for 10 minutes, and uniform blend pellets were obtained;

[0028] (2) Injection molding: Add the blend pellets in step (1) to the hopper of the injection molding machine, and the blend pellets are melted by the heating screw in the heating barrel to form a fluid with uniform properties, and inject it with a gate mold , holding pressure, cooling molding, demoulding, to obtain the product.

Embodiment 3

[0030] An injection molding process for preventing injection overflow, comprising the following steps:

[0031] (1) Preparation of modified polyethylene: 970 parts of low-density polyethylene, 29 parts of high-density polyethylene and 1 part of slip agent were mixed, stirred for 10 minutes, and uniform blend pellets were obtained;

[0032] (2) Injection molding: Add the blend pellets in step (1) to the hopper of the injection molding machine, and the blend pellets are melted by the heating screw in the heating barrel to form a fluid with uniform properties, and inject it with a gate mold , holding pressure, cooling molding, demoulding, to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com