A kind of nanoporous metal powder and preparation method thereof

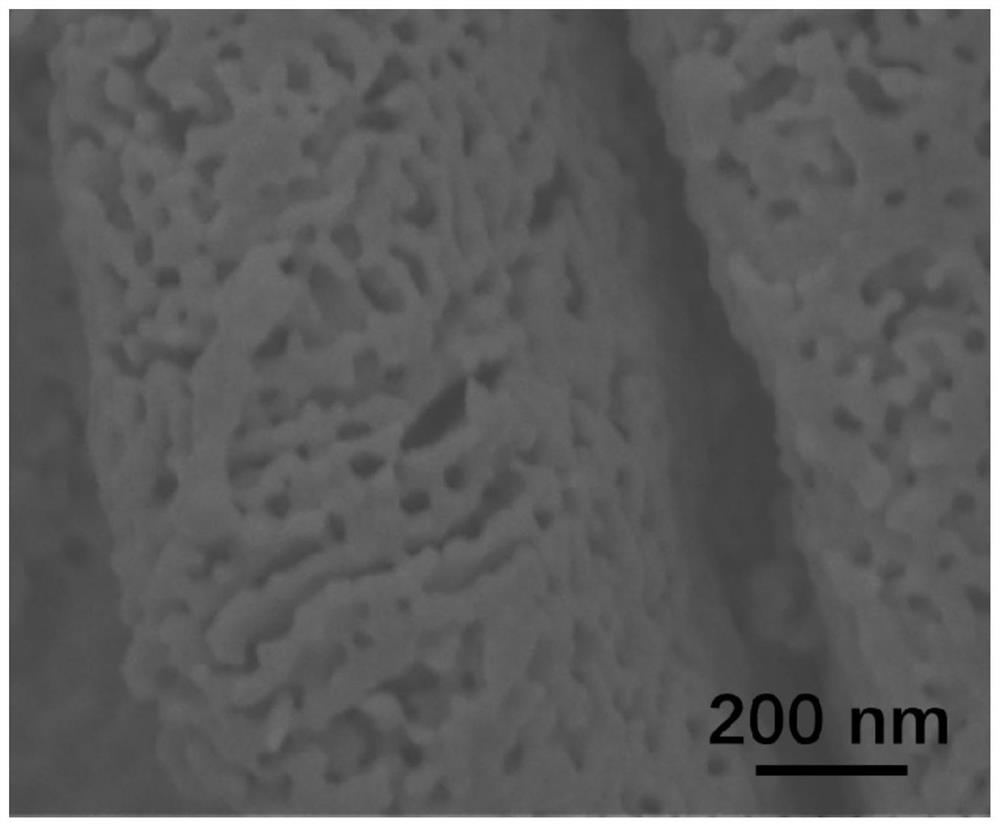

A nanoporous, metal powder technology, applied in metal processing equipment, nanotechnology, nanotechnology, etc., can solve problems such as difficult to precisely control the shape, and achieve the effects of low cost, large specific surface area, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

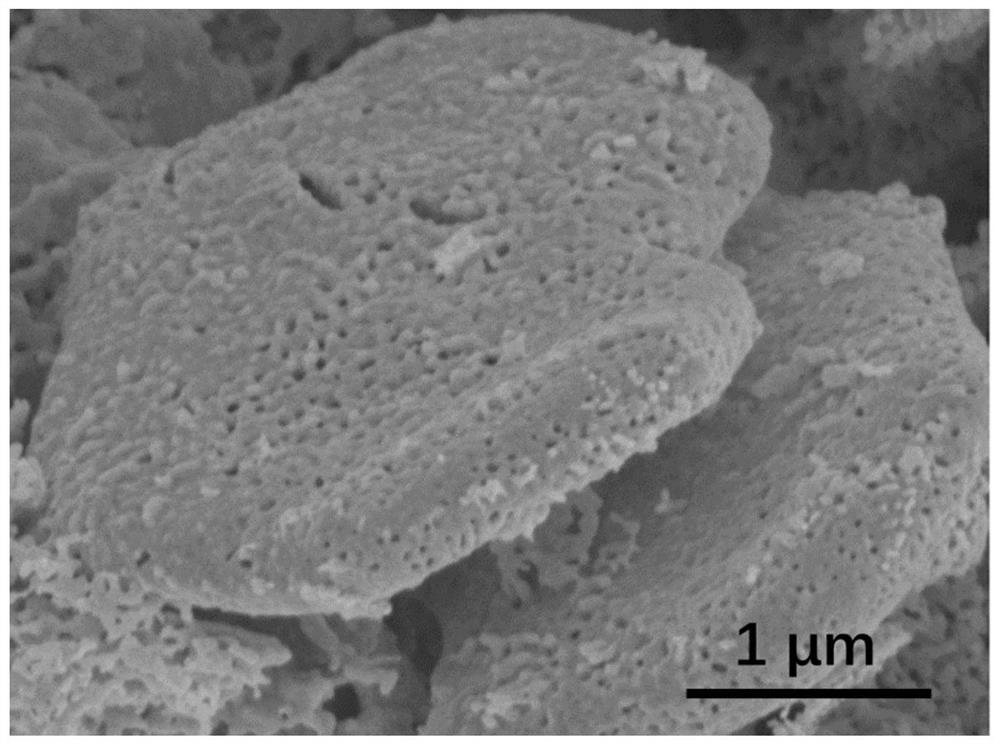

[0027] The preparation method of the nanoporous metal powder provided by the invention comprises:

[0028] S1, by molecular formula Mg a Cu b m c RE d Weigh raw materials, wherein, M is selected from at least one of Au, Pt, Pd, Ru, Rh, and Ir, RE is at least one of rare earth elements, and a, b, c, and d represent the atomic hundred of each element respectively. content, and 55%≤a≤70%, 15%≤b≤25%, 2%≤c≤10%, a+b+c+d=100%, the raw material is melted and then solidified in the first rate cooling to room temperature to obtain the first alloy, wherein the solidified structure of the first alloy includes a M-rich primary crystal phase and a first matrix phase, and the primary crystal phase includes at least one of M and Cu, RE, The shape of the primary crystal phase is a sheet-like hexagon, and the melting point of the primary crystal phase is T m , the melting point of the first matrix phase is T n ,T n m ;

[0029] S2, heating the first alloy to a temperature T, and then co...

Embodiment 1

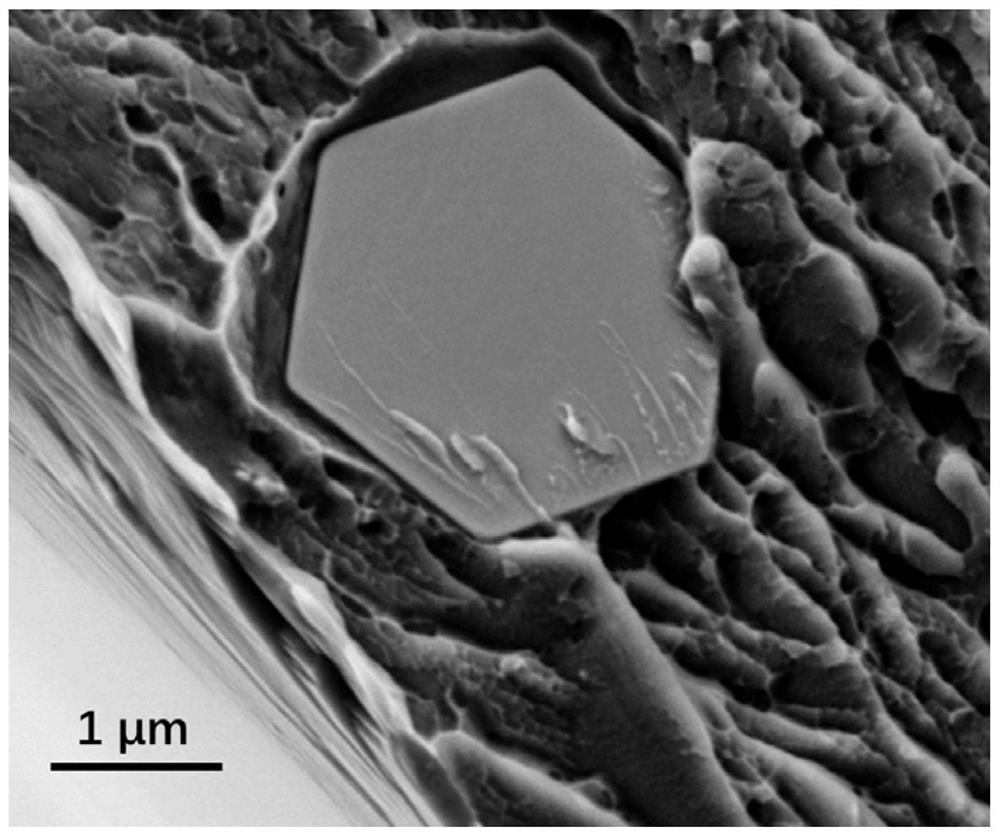

[0047] Select the ingredient as Mg 61 Cu 23 Au 5 Gd 11 According to the composition of the elements, the alloy is prepared according to the composition of the elements, and the alloy is fully induction melted, and then the alloy melt is solidified to room temperature at a rate of 50K / s, and the composition is Mg 61 Cu 23 Au 5 Gd 11 the first alloy. During the solidification process, the Au-rich primary crystal phase with the elemental composition of Au-Cu-Gd is first precipitated, and the remaining melt with the ability to form amorphous solidifies to become the first matrix phase. The melting point of the primary crystal phase is 520 ° C, the first The melting point of the matrix phase is 475°C.

[0048] The first alloy is reheated to 500° C. to melt the first matrix phase, while the Au-rich Au-Cu-Gd primary crystal phase does not melt, and a semi-solid alloy melt is obtained. The semi-solid alloy melt is passed through the copper roll stripping technique in ~10 6 Af...

Embodiment 2

[0051] Select the ingredient as Mg 61 Cu 20 Au 5 Pt 2 PD 1 Gd 11 According to the composition of the elements, the alloy is prepared according to the composition of the elements, and the alloy is fully induction melted, and then the alloy melt is solidified to room temperature at a rate of 10K / s, and the composition is Mg 61 Cu 20 Au 5 Pt 2 PD 1 Gd 11 the first alloy. During the solidification process, the Au-Pt-Pd-rich primary crystal phase with the elemental composition (Au-Pt-Pd)-Cu-Gd is first precipitated, while the remaining melt with amorphous forming ability solidifies as the first matrix phase, The primary crystal phase has a melting point of 525°C and the first matrix phase has a melting point of 480°C.

[0052] The first alloy was reheated to 510°C so that the first matrix phase melted, while the Au-Pt-Pd-rich primary phase with the elemental composition (Au-Pt-Pd)-Cu-Gd did not melt, resulting in a semi-solid state alloy melt. The semi-solid alloy melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com