A method for ultra-high-speed laser cladding on the end face of disk parts

A disc-type parts, laser cladding technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of less ultra-high-speed laser cladding, less research on the end face cladding process of disc parts, etc., to improve the overall The effect of cladding quality, guaranteed cladding efficiency and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

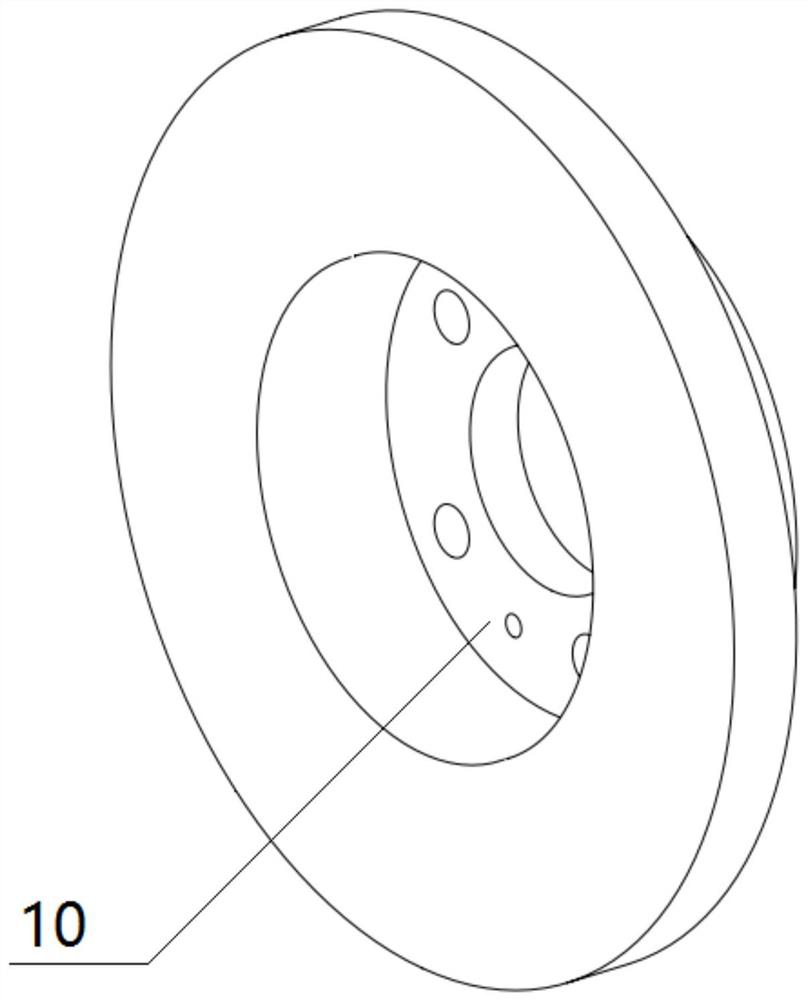

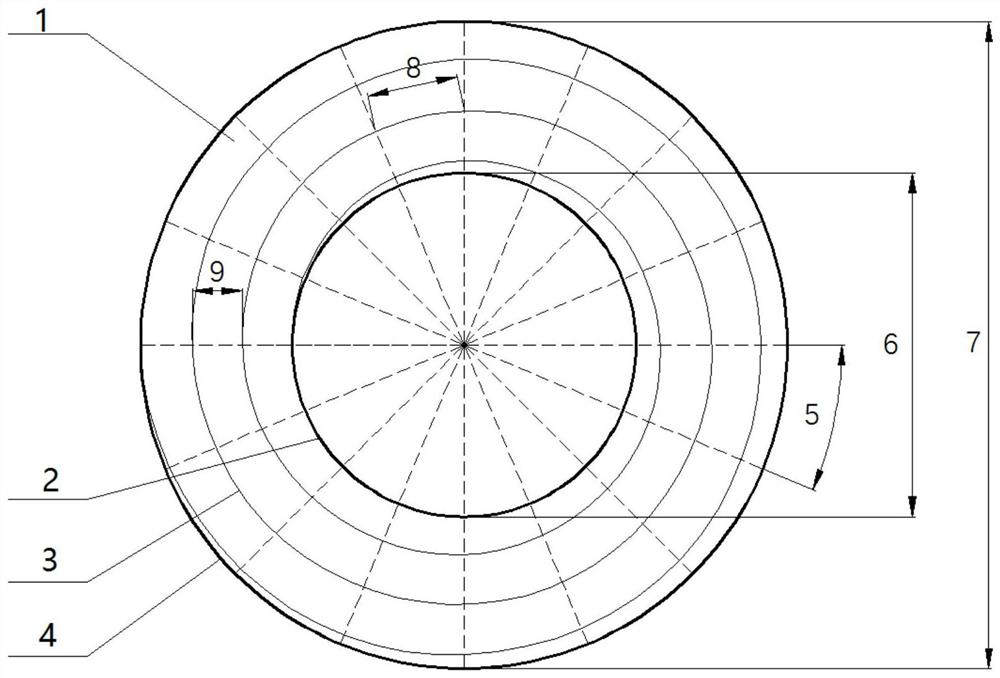

[0070] For a certain type of brake disc, the end surface to be clad is circular, with an outer diameter of Φ800mm, an inner diameter of Φ200mm, a thickness of 30mm, and a base material of 35CrMo. The surface is subjected to single-layer ultra-high-speed laser cladding, and the cladding powder is selected Iron-based stainless steel powder, the cladding process is carried out through the following process steps:

[0071] S1. Carry out machining treatment on the end surface of the brake disc, check the end surface of the brake disc to ensure that the surface quality is free from defects.

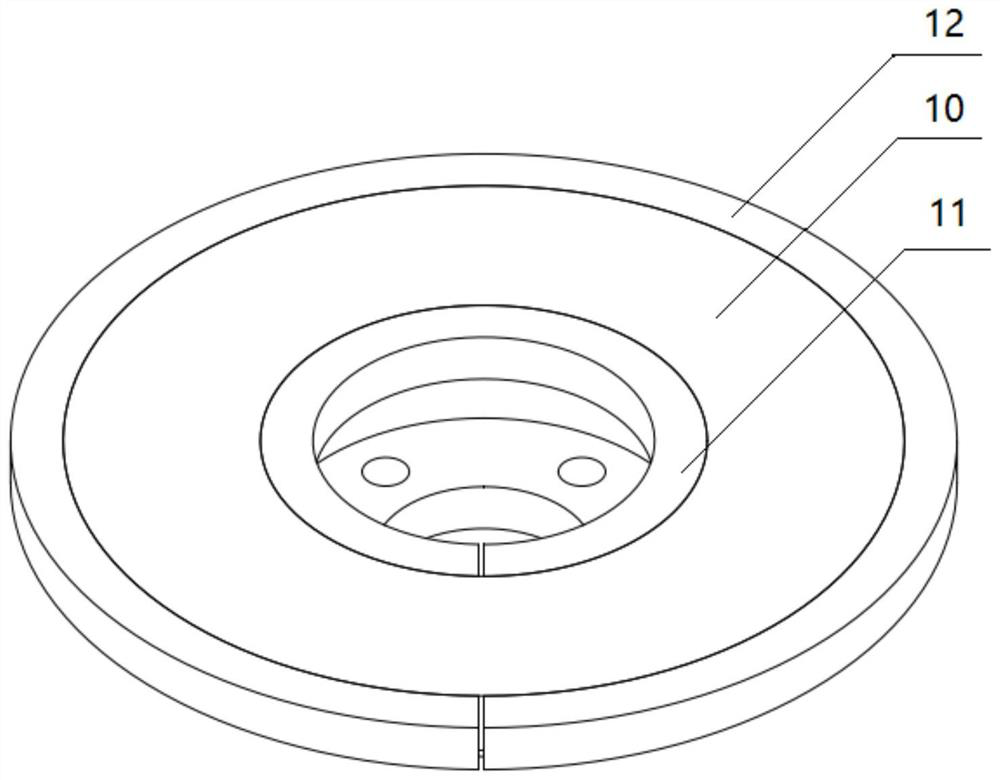

[0072] S2, install the customized notched ring I and notched ring II on the outer circle and inner hole of the brake disc. The notch width of the notched ring I used is 1mm, the inner diameter of the notched ring I is Φ800mm, the outer diameter is Φ810mm, and the thickness is 10mm. The inner ring of the notched ring I is provided with a rectangular groove with a depth of 3mm and a width of 3mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com