Laser cladding cooling device with fin type cooling fins

A laser cladding and cooling device technology, which is applied in household refrigeration devices, lighting and heating equipment, metal material coating technology, etc., can solve the problem of ineffective cooling and heat dissipation of workpieces, limited size and structure of workpieces, and cooling effect of workpieces. Inconspicuous problems, to achieve the effect of heat dissipation, improve molding quality, and ensure cladding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

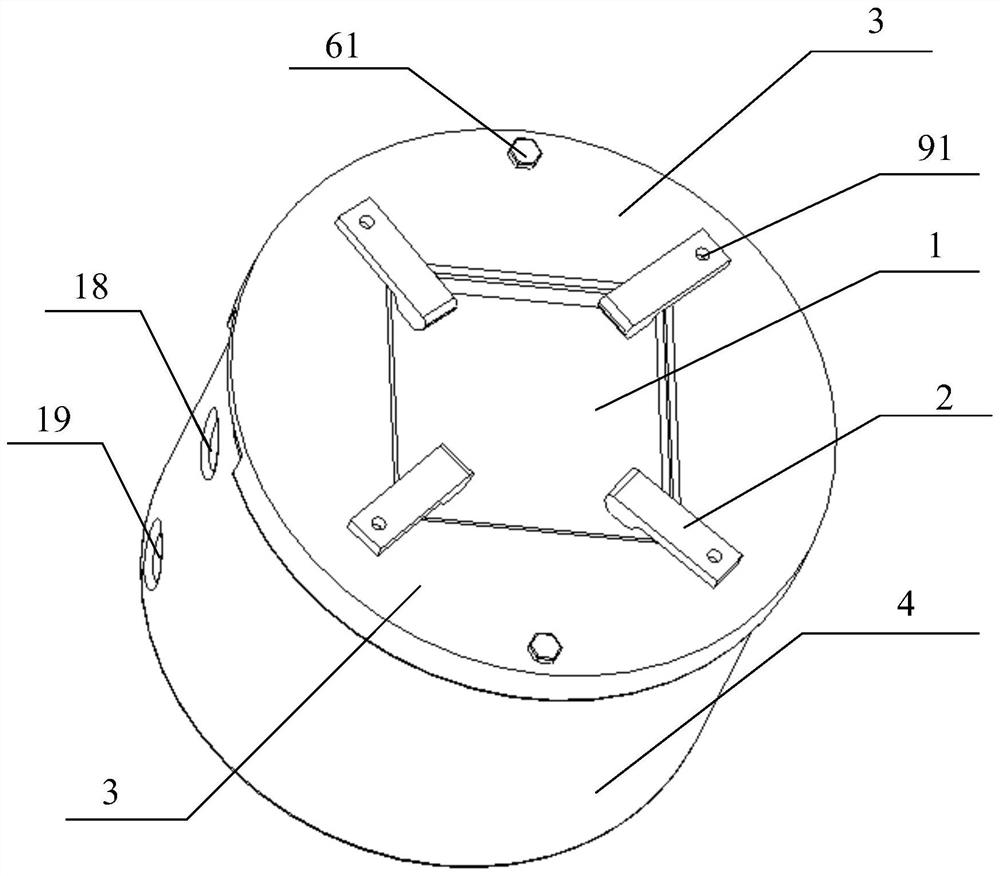

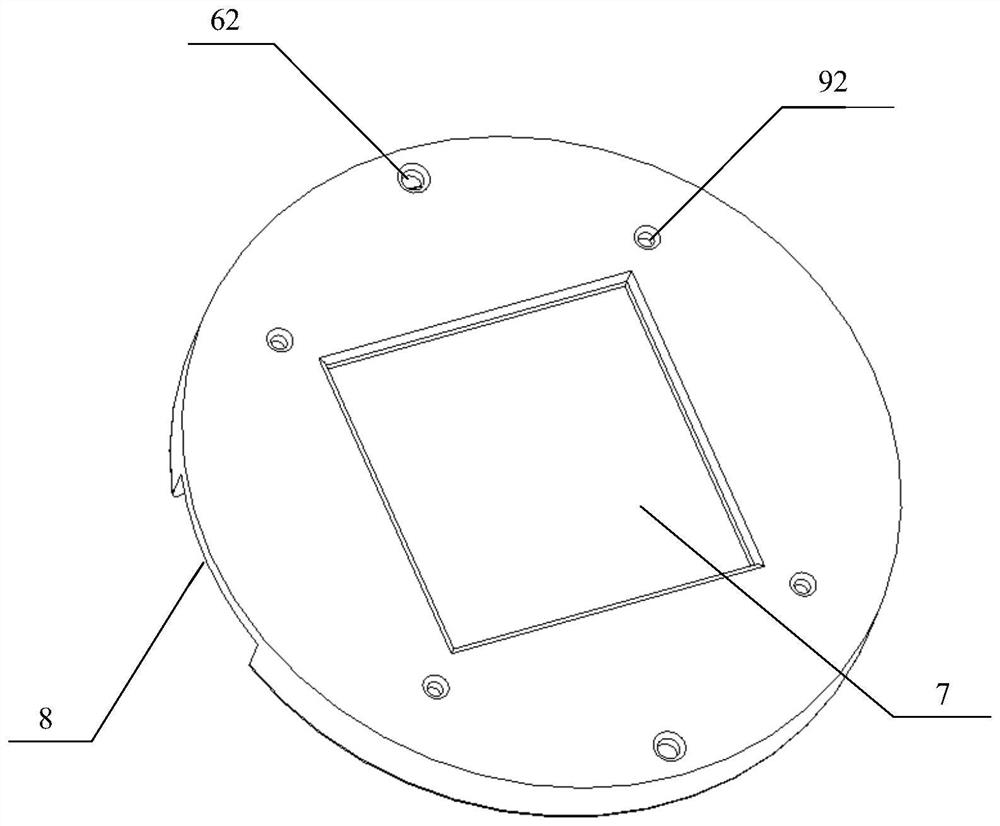

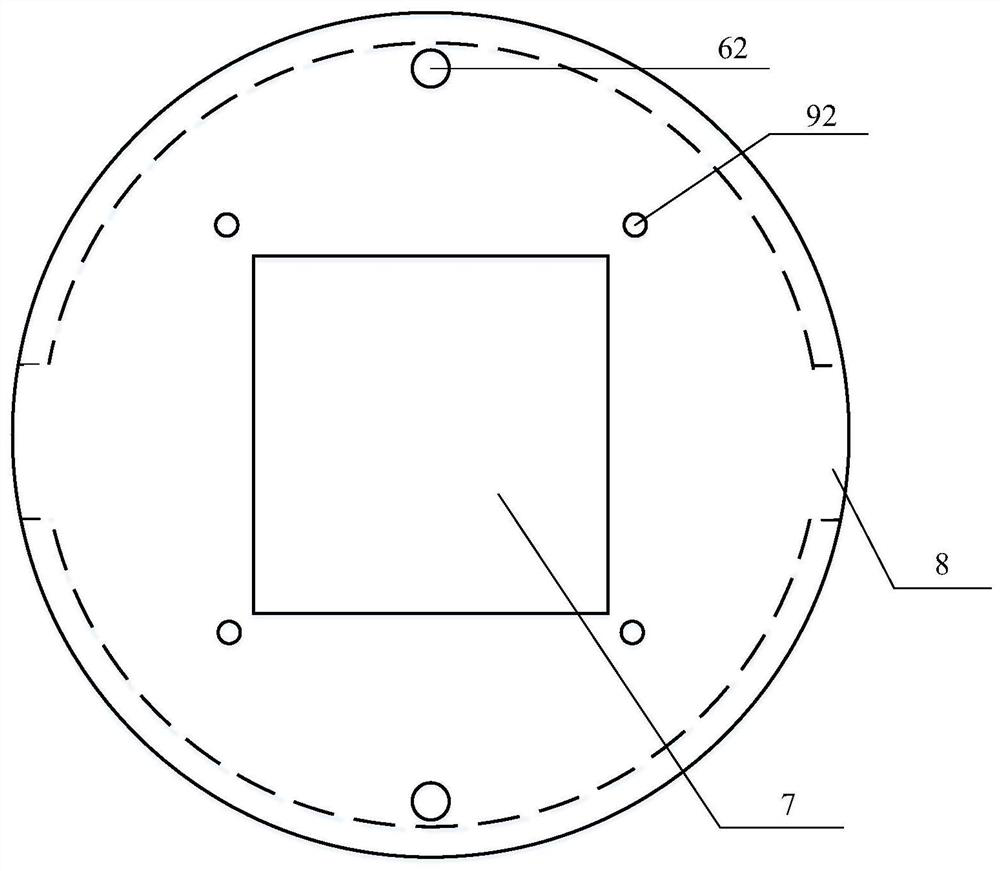

[0060] The present invention proposes an all-round and efficient forced cooling device for laser cladding substrates, the overall structure of which is as follows figure 1 As mentioned above, the cooling device includes a cooling plate 1 , a fixture 2 , a protective cover 3 , a cooling water tank 4 and a finned cooling fin 5 . The protective cover 3 is threadedly connected with the cooling plate 1 and the heat dissipation water tank 4, and a gasket is installed at the junction; The size of the square hole 7 set at the center of the main body of the protective cover 3 is the same as that of the base plate, and the side is provided with a side gap 8 slightly larger than the cooling water inlet channel 10 and the cooling water inlet channel 11; the four corners of the square hole 7 are provided with threaded holes d12 for easy fastening The bolt 61 passes through to install the fixture 2, and the protective cover 3 on the left and right sides of the square hole 7 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com