Four-point supporting and fixing device for double-fuselage model

A four-point support and fixing device technology, applied in the direction of measuring device, machine/structural component testing, elasticity testing, etc., can solve the problems affecting the experimental results, statically indeterminate structure, airframe vibration simulation interference, etc. Accurate results and small internal loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in conjunction with embodiment.

[0031] The invention provides a four-point support and fixing device for a double-fuselage model, which establishes a fully elastic support mechanism for a double-fuselage structure, uses the elastic support method to realize the real simulation of the structural characteristics of the aircraft, and provides reliable support for the development and innovation of the double-fuselage structure. test technical support.

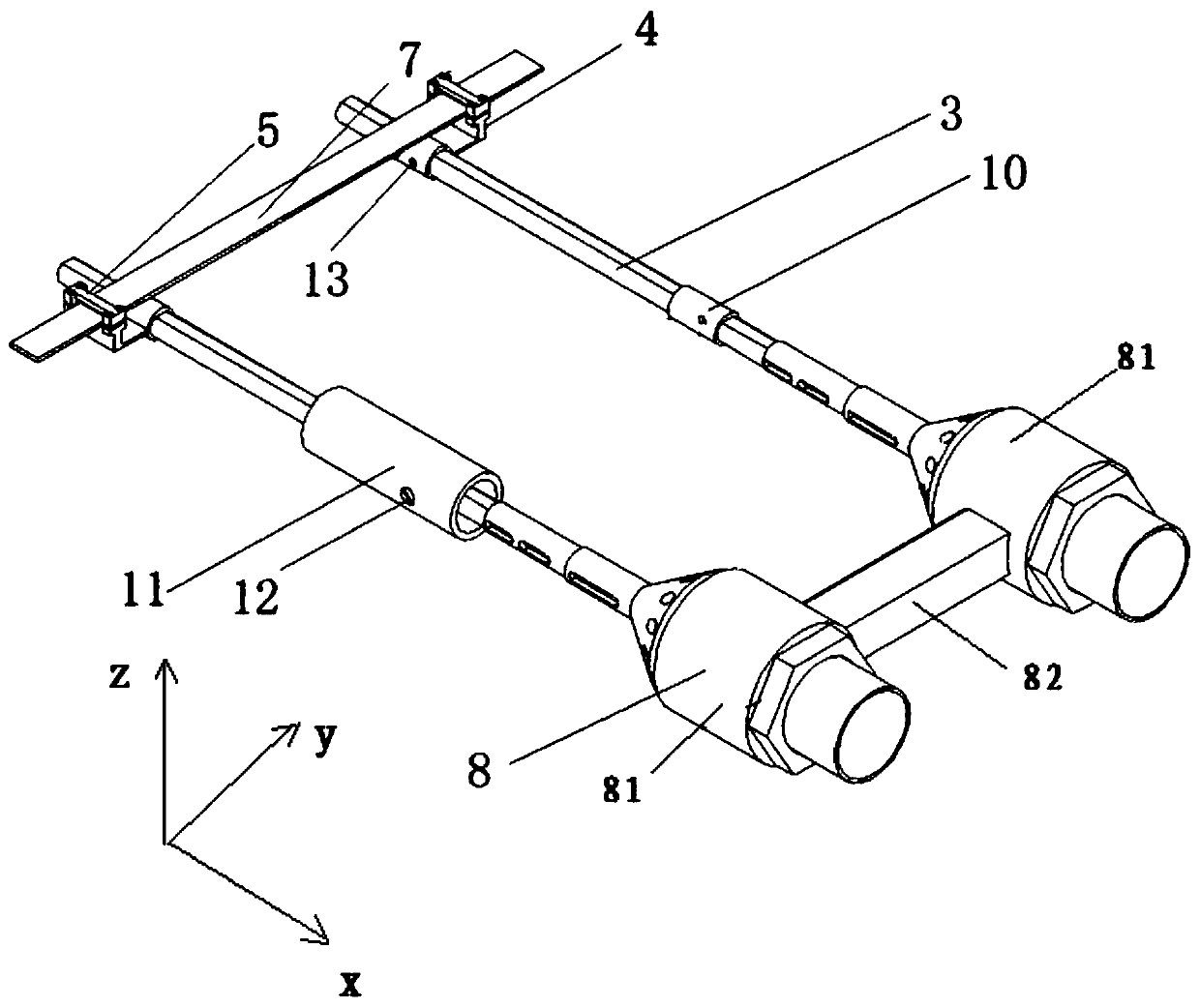

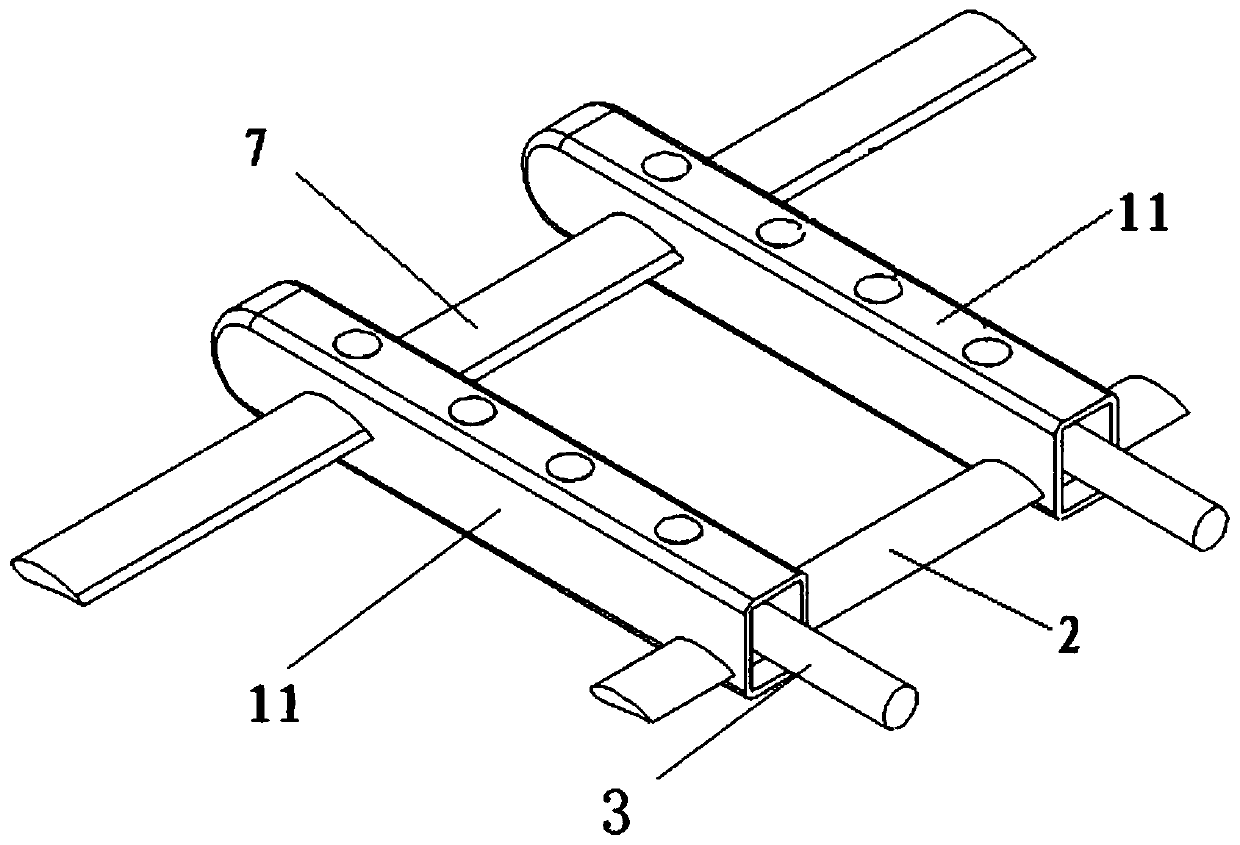

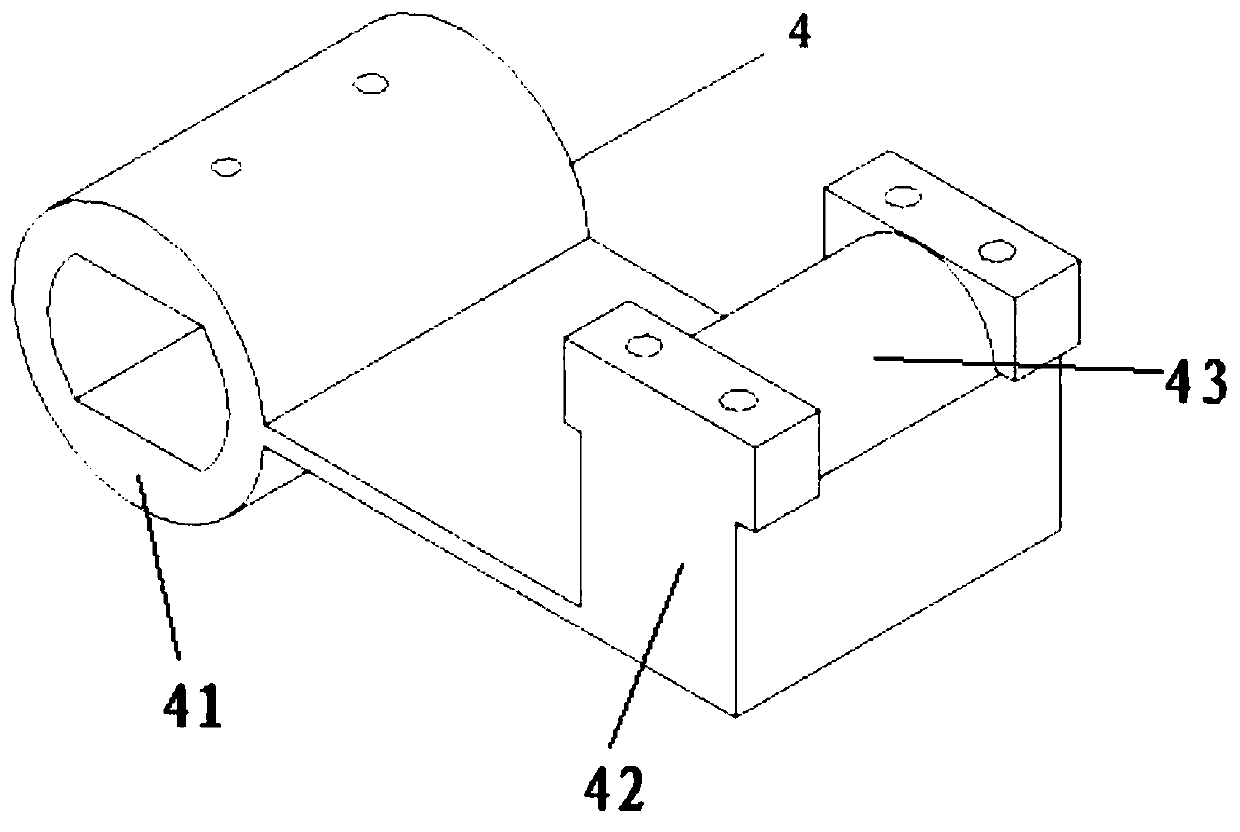

[0032] Such as figure 1 As shown, the four-point support fixture mainly includes double-hole fixed scimitars 8, 2 poles 3, 2 rear node support sleeves 10, 2 front node support sleeves 4, 2 front node cylinder fixing plates 5, 2 rear node fixing bolts 12, 2 front support sleeve fastening studs 13 and the external double fuselage model; wherein, the double-hole fixed scimitar 8 includes 2 hollow columnar connecting cylinders 81 and 1 connecting rod 82; 2 The connecting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com