a nb 3 Repair method of sn superconducting wire

A repair method, superconducting wire technology, applied in the usage of superconducting elements, superconducting magnets/coils, superconducting devices, etc., can solve the problem of destroying the superconducting performance of superconducting magnets, damaged wires, and the difficulty of regenerating Sn superconducting magnets. Use and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

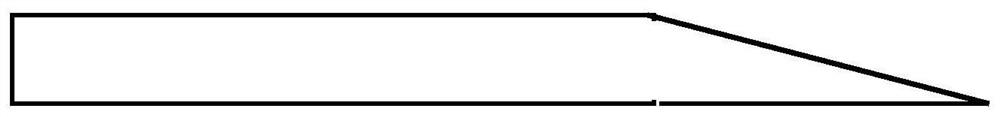

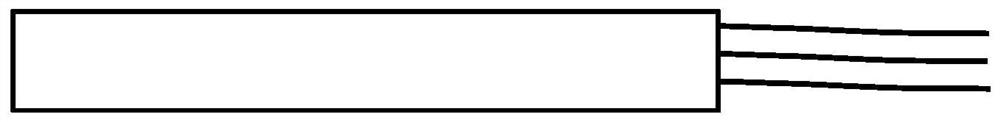

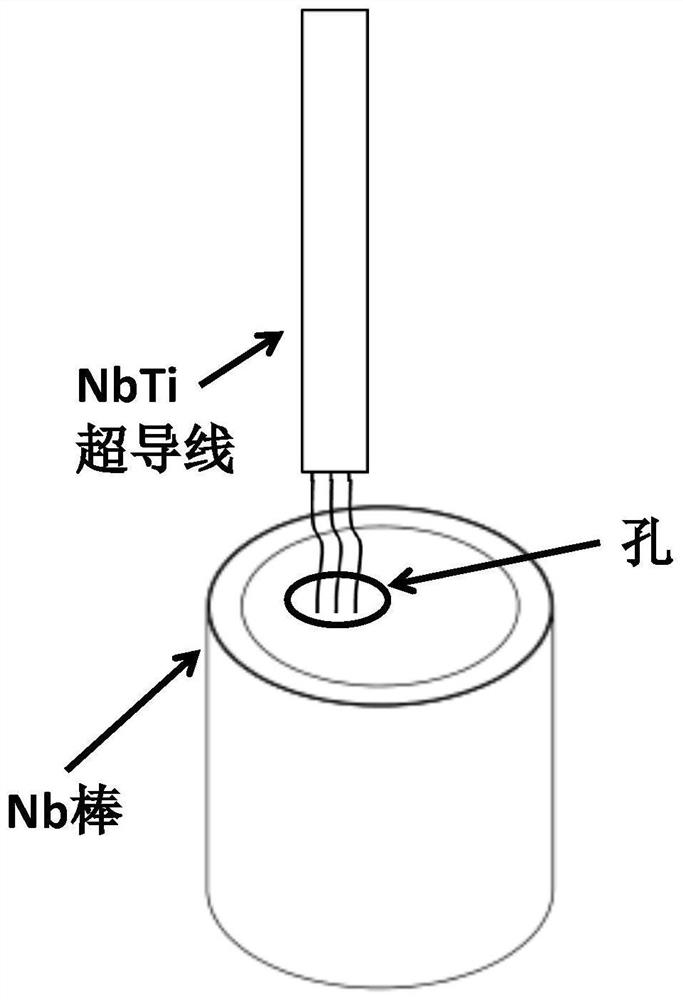

[0043] Nb that will have the point of failure 3 The Sn superconducting wire was cut into a fracture with a wedge angle of 15° with scissors. The copper layer at the end of a NbTi superconducting wire is etched with nitric acid to expose the NbTi superconducting multifilament. Take a piece of Nb rod, drill a counterbore in the center of the Nb rod, the diameter of the hole is 1 mm, insert the NbTi multi-wire into the center hole of the Nb rod, put the Nb rod together with the NbTi superconducting wire under the press and press it horizontally, the pressure of the press is 10t, NbTi multifilaments embedded in Nb rods. Then holes are drilled on the Nb rod near the NbTi multifilament. Put the Nb rod into the copper cup, punch a hole in the center of the bottom of the copper cup, and the center hole of the copper cup is coaxial with the through hole of the Nb rod. Ball mill the Nb powder and Sn powder for 2 hours, the molar ratio of Nb powder and Sn powder is 1:1, and the partic...

Embodiment 2

[0045] will destroy Nb 3 The Sn superconducting wire was cut with scissors into a fracture with a wedge-shaped angle of 30°. The copper layer at the end of a NbTi superconducting wire is etched with nitric acid to expose the NbTi superconducting multifilament. Take a piece of Nb rod, drill a counterbore in the center of the Nb rod, the diameter of the hole is 5mm, and insert the NbTi multi-wire into the center hole of the Nb rod. Put the Nb rod together with the NbTi superconducting wire under a press and press it horizontally. The pressure of the press is 2t, so that the NbTi multifilaments are embedded in the Nb rod. Then holes are drilled on the Nb rod near the NbTi multifilament. Put the Nb rod into the copper cup, punch a hole in the center of the bottom of the copper cup, and the center hole of the copper cup is coaxial with the through hole of the Nb rod. The Nb powder and the Sn powder were ball milled for 20 hours, the molar ratio of the Nb powder and the Sn powder...

Embodiment 3

[0047] will destroy Nb 3 The Sn superconducting wire was cut into a fracture with a wedge angle of 22° with scissors. The copper layer at the end of a NbTi superconducting wire is etched with nitric acid to expose the NbTi superconducting multifilament. Take a piece of Nb rod, drill a counterbore in the center of the Nb rod, the diameter of the hole is 2.5mm, insert the NbTi multi-wire into the center hole of the Nb rod, put the Nb rod together with the NbTi superconducting wire under the press and press it horizontally, the press The pressure is 6t, so that the NbTi multifilaments are embedded in the Nb rod. Then holes are drilled on the Nb rod near the NbTi multifilament. Put the Nb rod into the copper cup, and punch a hole in the center of the bottom of the copper cup, which is coaxial with the through hole of the Nb rod. Mix Nb powder and Sn powder, ball mill for 10h, the molar ratio of Nb powder and Sn powder is 3:1, and the particle size of Nb powder and Sn powder is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com