Preparation method of iron-based REFeAsO1-xFx superconducting material

A superconducting material, iron-based technology, which is applied in the field of preparation of iron-based REFeAsO1-xFx superconducting materials, can solve the problems of large deviation of separation schedule, easy rupture of quartz tubes, complicated high-voltage equipment, etc., and achieves composition determination and single-phase property. Good, high superconducting transition temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

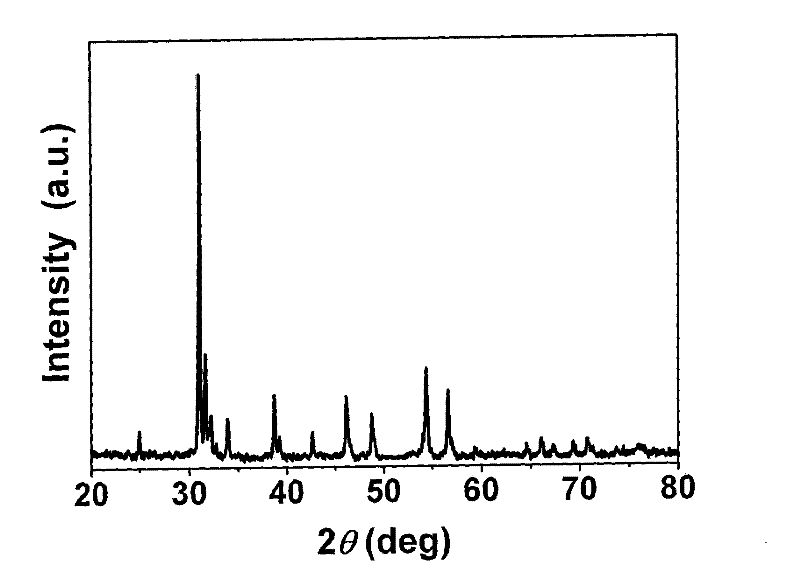

[0022] An Fe-based REFeAsO 1-x f x A method for preparing a superconducting material, RE is one of lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), samarium (Sm) or gadolinium (Gd), when RE is La, 0.03≤ x≤0.2; when RE is one of Ce, Pr, Nd, Sm or Gd, 0.05≤x≤0.35. In this example, RE is Sm, x=0.05, and its specific method is:

[0023] a. Prepare materials according to iron-based SmFeAsO 0.95 f 0.05 The stoichiometric ratio of superconducting materials, under the argon protective atmosphere, weigh SmAs, Fe, Fe respectively 2 o 3 And SmF with a particle size of 5-100 nanometers 3 Nanoscale powder, mixed and ground evenly and then pressed into tablets;

[0024] b. Tube sealing In an argon protective atmosphere, wrap the pressed tablet with a tantalum sheet, and then seal it in a vacuum quartz tube;

[0025] c. Sintering Put the quartz tube into a sintering furnace, raise the temperature to 1100°C at a rate of 100°C / hour under an argon protective atmosphere, k...

Embodiment 2

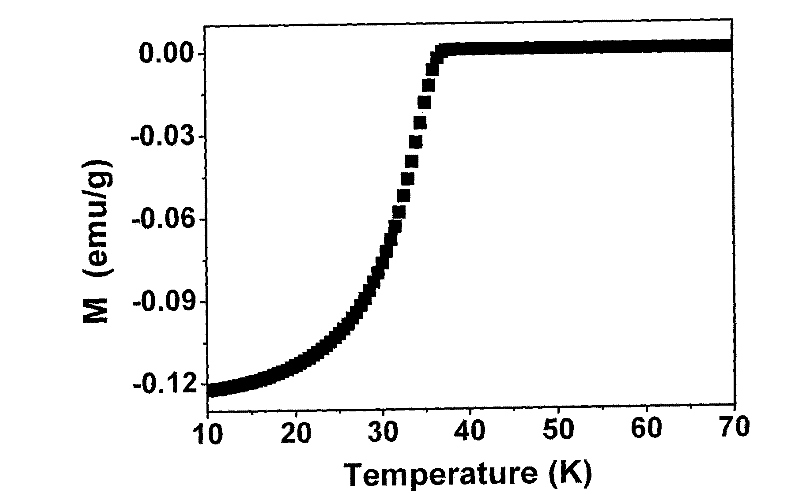

[0028] This example is basically the same as Example 1, the difference is only: iron-based SmFeAsO 1-x f x x = 0.10 of the superconducting material; during c-step sintering, the temperature is raised to 1050°C at a rate of 200°C / hour and kept for 42 hours to obtain SmFeAsO 0.9 f 0.1 superconducting material. Experimental measurement of its superconducting transition temperature is 46K.

Embodiment 3

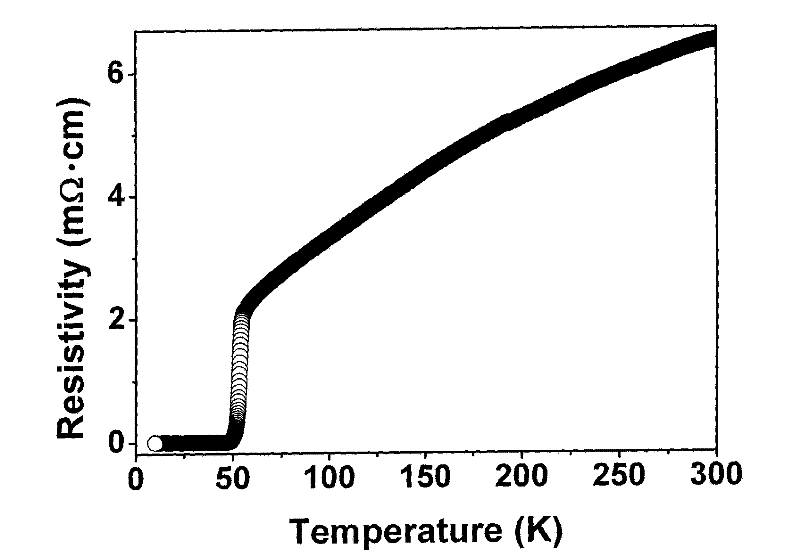

[0030] This example is basically the same as Example 1, the difference is only: iron-based SmFeAsO 1-x f x x = 0.20 of the superconducting material; during c-step sintering, the temperature is raised to 1100°C at a rate of 150°C / hour and kept for 50 hours to obtain SmFeAsO 0.8 f 0.2 superconducting material.

[0031] image 3 For the iron-based SmFeAsO prepared by the method of this example 0.8 f 0.2 The electrical resistance of a superconducting material varies with temperature. Depend on image 3 The phenomenon of zero resistance can be clearly observed, and its superconducting transition temperature is 55K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com