A kind of highland barley berry honey and its preparation method

A technology for highland barley and highland barley is applied in the field of barley barley honey and its production, which can solve the problems of single product and low added value, and achieve the effects of good taste, increased added value and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

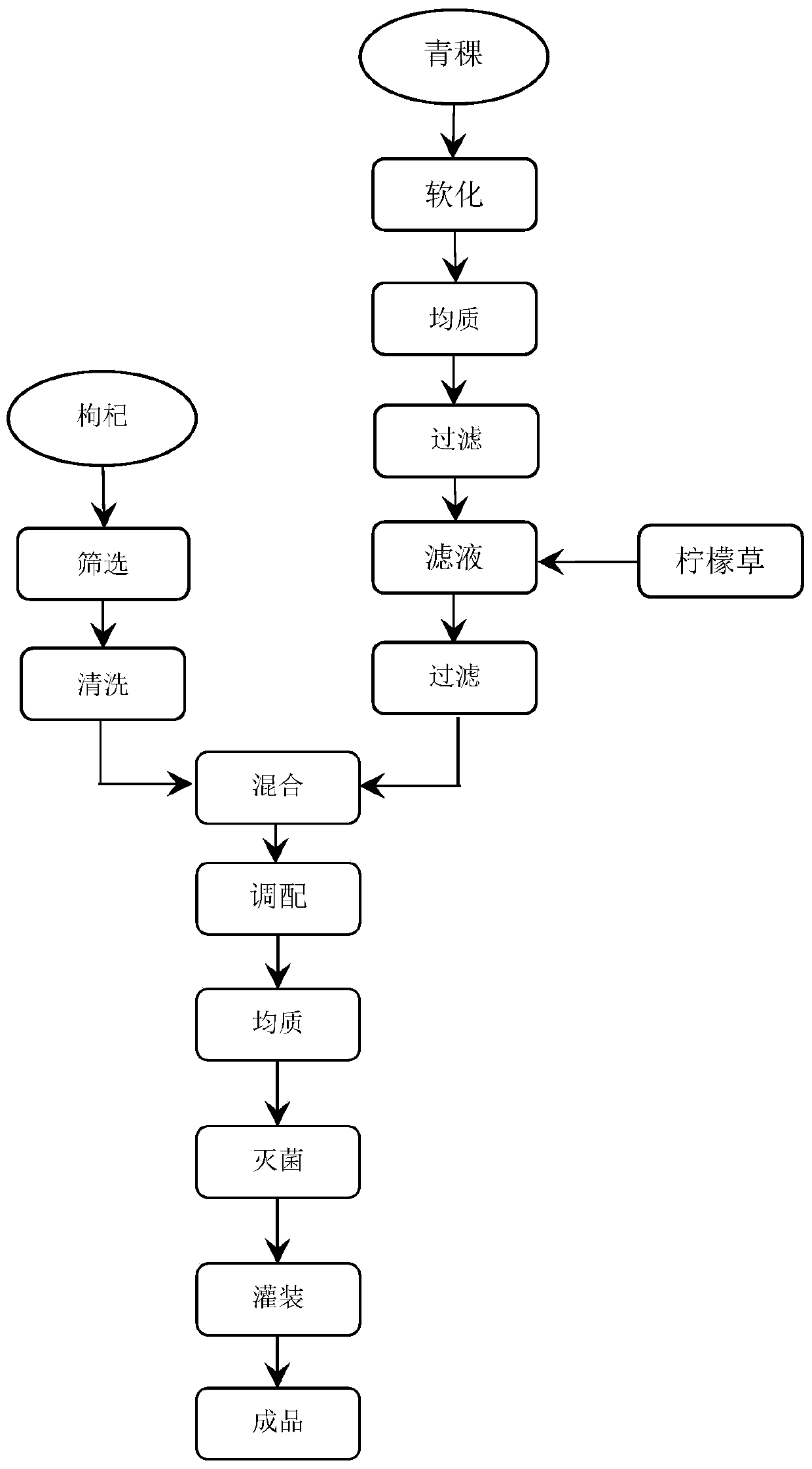

[0025] Add 2 kg of water to 1 kg of highland barley, 0.10 MPa, soften at 105° C. for 6 minutes, add 45 kg of water to the softened highland barley, mix, beat, and filter to obtain 48 kg of highland barley liquid;

[0026] Add 137g of lemongrass to the obtained highland barley liquid, extract at 78°C for 60 minutes, filter, collect the filtrate, and obtain 47.5 kg of highland barley liquid;

[0027] Add 47.5kg of Chinese wolfberry to 47.5kg of prepared highland barley liquid, mix, beat, and homogenize to obtain 95kg of highland barley liquid.

[0028] Take 22kg of highland barley wolfberry liquid, add 65kg of high fructose syrup, 6kg of honey, 2.4kg of citric acid, 2.5kg of sodium citrate, 2.05kg of guar gum and 0.05kg of CMC, and mix evenly to obtain 100kg of highland barley honey.

Embodiment 2

[0030] Take 30 kg of highland barley wolfberry liquid prepared in Example 1, add 57 kg of fructose syrup, 6 kg of honey, 2.4 kg of citric acid, 2.5 kg of sodium citrate, 1.85 kg of guar gum and 0.25 kg of CMC, and mix evenly to obtain highland barley Qimi 100kg.

Embodiment 3

[0032] Add 3 kg of water to 1 kg of highland barley, 0.13 MPa, soften at 121° C. for 5 minutes, add 100 kg of water to the softened highland barley, mix, beat, and filter to obtain 104 kg of highland barley liquid;

[0033] Add 231g of lemongrass to the obtained highland barley liquid, extract at 85°C for 20min, filter, collect the filtrate, and obtain 334kg of highland barley liquid;

[0034] 334kg of highland barley liquid was added into 278kg of wolfberry and mixed, beaten and homogenized to obtain 612kg of highland barley liquid.

[0035] Take 31kg of highland barley wolfberry liquid, add 58.6kg of high fructose syrup, 6kg of honey, 1.6kg of citric acid, 1.79kg of sodium citrate, 1kg of guar gum and 0.01kg of CMC, and mix evenly to obtain 100kg of highland barley honey.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com