Pot cover device with turner

A technology for spatulas and pot lids, which is applied to cooking utensil lids, inserts, cooking utensils, etc., can solve the problems of motor damage, high maintenance frequency, and reduced service life, and achieve the effects of simplifying control, reducing costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

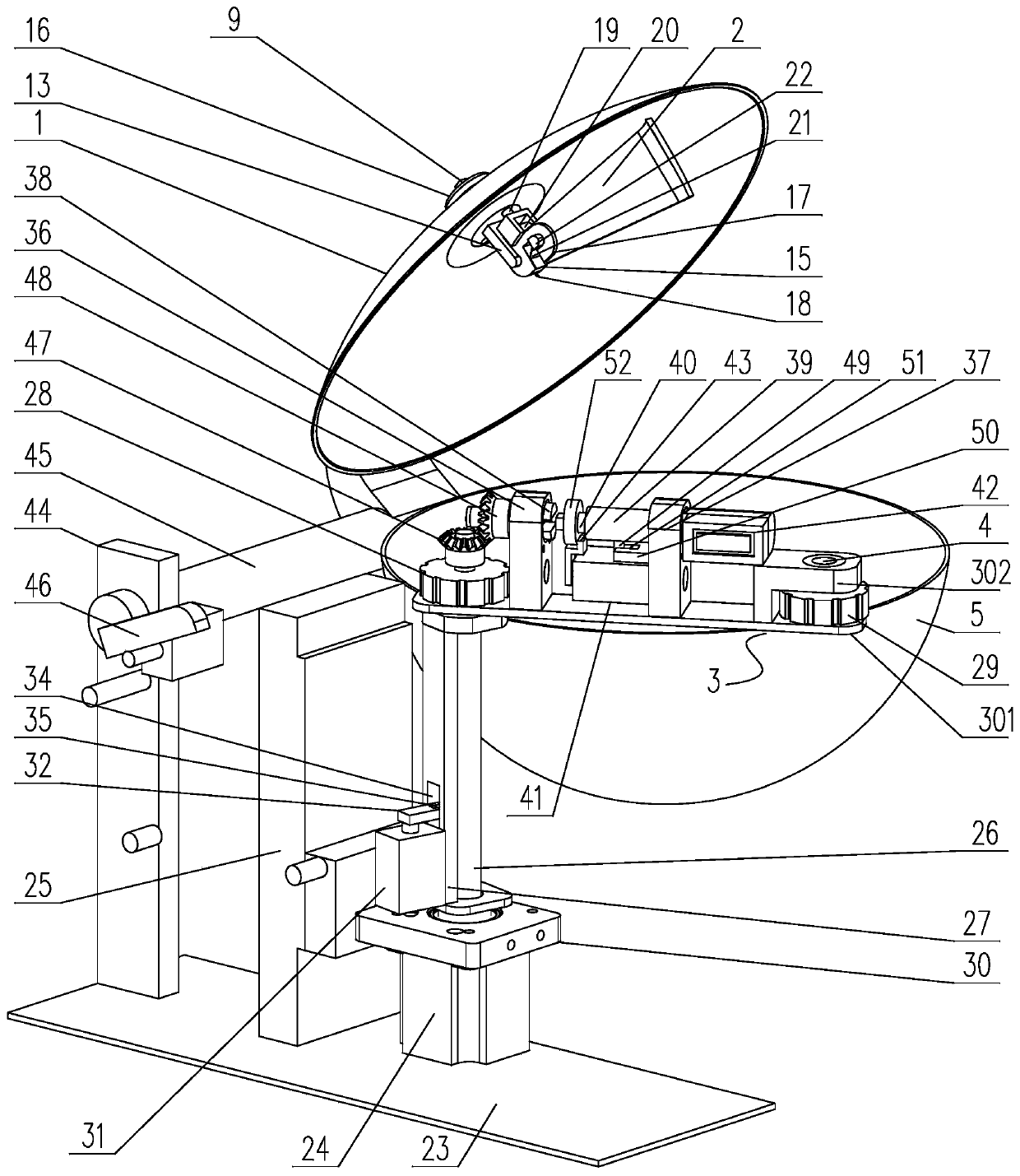

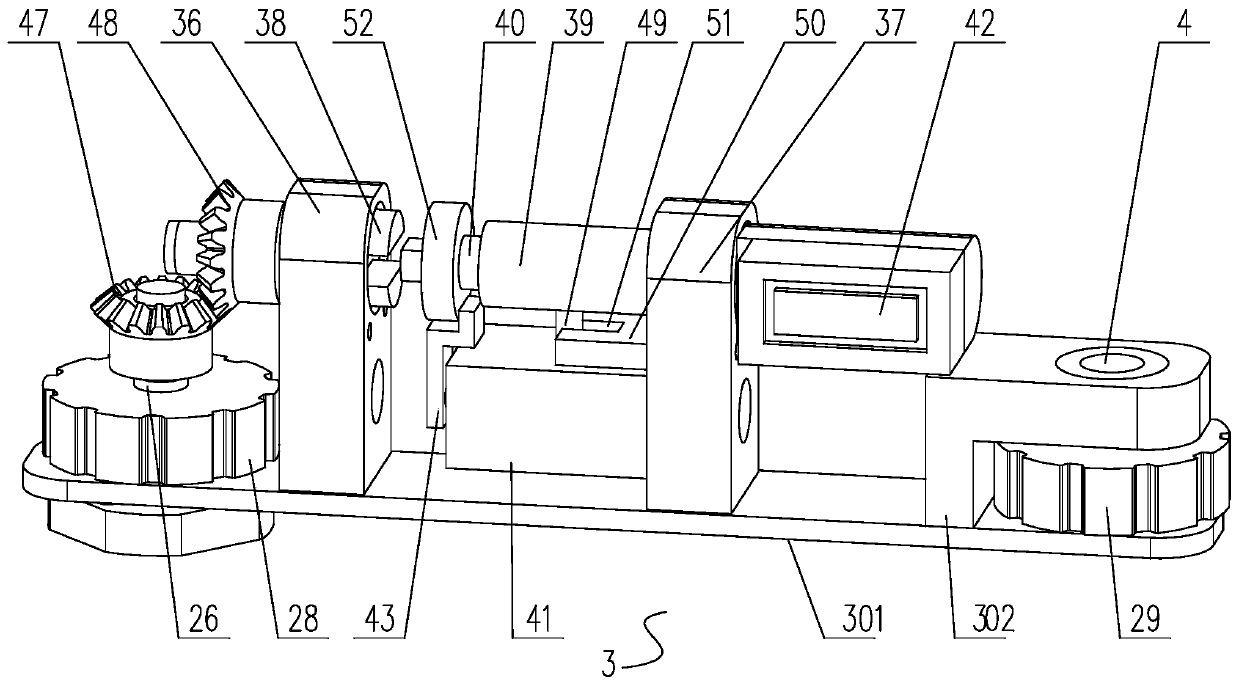

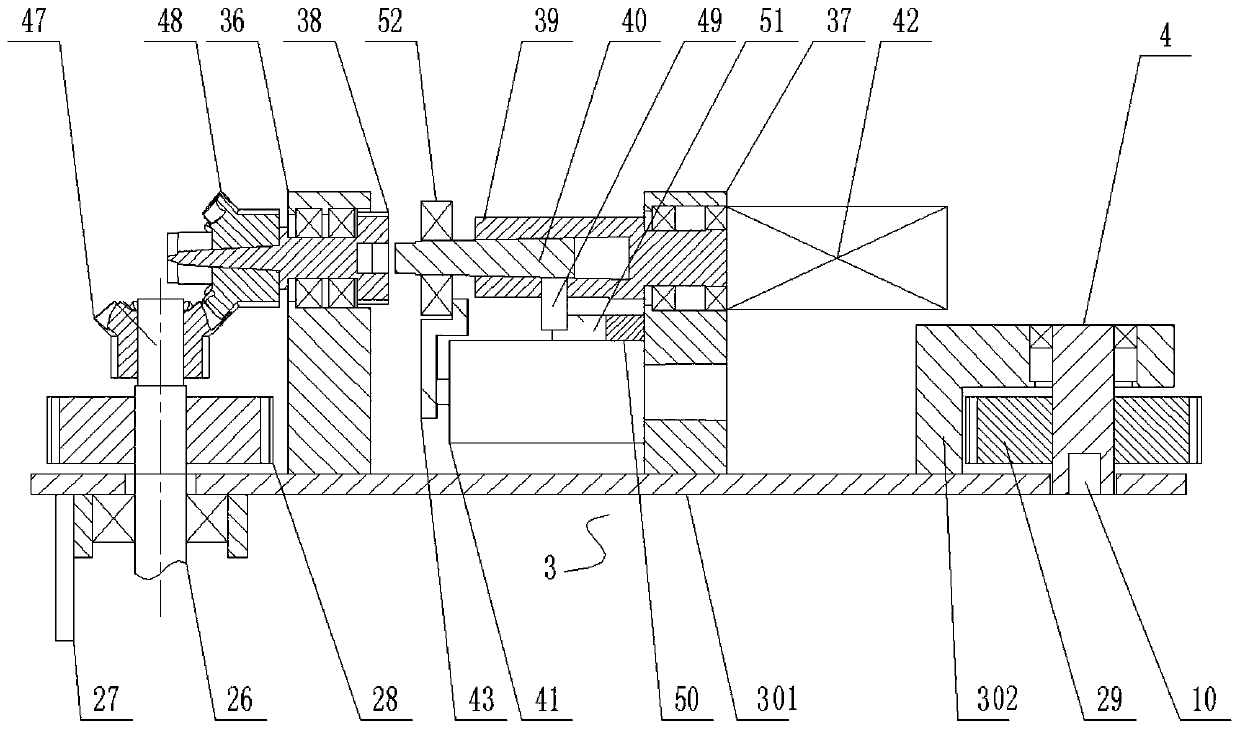

[0050] Such as Figure 1 to Figure 9 As shown, the present invention is provided with a pot cover device with a spatula, comprising a pot cover 1, a spatula 2 mounted on the inside of the pot cover 1 through a rotation pair, a drive assembly for driving the spatula 2 to rotate, and fixing the pot cover 1 On the base plate 23 and supported on the support assembly above the frying pan 5, the drive assembly includes a rotary lifting platform, a support arm 3 fixed on the rotary lifting platform, a drive mechanism installed on the support arm 3 and a rotation mechanism arranged on the support arm. 3 on the upper rotating shaft 4, the rotary lifting platform drives the support arm 3 to rotate around the straight line vertical to the horizontal plane and move up and down along the straight line vertical to the horizontal plane. Driven by the rotary lifting platform, the upper rotating shaft 4 can be moved to Above the rotating pair, and coaxially inserted with the rotating pair, the...

Embodiment 2

[0059] This embodiment is based on the first embodiment, and makes a specific implementation description for the structure of the rotary pair.

[0060] Such as Figure 3 ~ Figure 7 As shown, in the present invention, the rotating pair includes a bearing A6 and a lower rotating shaft 7, and a mounting hole 8 is provided on the pot cover 1, and the bearing A6 is located in the mounting hole 8 and sleeved on the lower rotating shaft 7 , and the inner and outer rings of the bearing A6 are interference fit with the lower rotating shaft 7 and the mounting hole 8 respectively;

[0061] The upper rotating shaft 4 is plugged coaxially with the lower rotating shaft 7;

[0062] The bottom of the lower rotating shaft 7 is disconnected from the spatula 2 .

[0063] If the pot cover is directly rotatably connected with the lower rotating shaft 7 through bearings, the thickness of the pot cover will be large and the material cost will increase; while the thickness of the pot cover is small...

Embodiment 3

[0068] This embodiment is based on the second embodiment, and further optimizes the fixing of the spatula 2.

[0069] Such as Figure 3 ~ Figure 7 As shown, in the present invention, a collar 16 is provided at the middle of the insertion shaft 9, and the lower rotating shaft 7 is disassembled and connected with the spatula 2 through a disassembly assembly, which includes a hinge arm 13, a hinge shaft 14. The hinge block 15 and the push rod 19, the upper and lower ends of the hinge arm 13 are respectively connected to the lower rotating shaft 7 and the hinge shaft 14, the axis of the hinge shaft 14 is parallel to the horizontal plane, and the hinge block 15 The top is hinged with the hinged arm 13 through the hinged shaft 14, and its bottom is clamped with the spatula 2;

[0070] A return spring 18 is arranged between the hinged arm 13 and the hinge block 15, and when the return spring 18 is in its original state, the spatula 2 is in a horizontal position, that is, the spatula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com