Dental multicolour grinding block

A restoration and milling technology, used in dentistry, dental prostheses, dentures, etc., can solve the problems of unsatisfactory appearance of teeth and the inability to reduce the number of layers, and achieve the effect of good dispersion and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

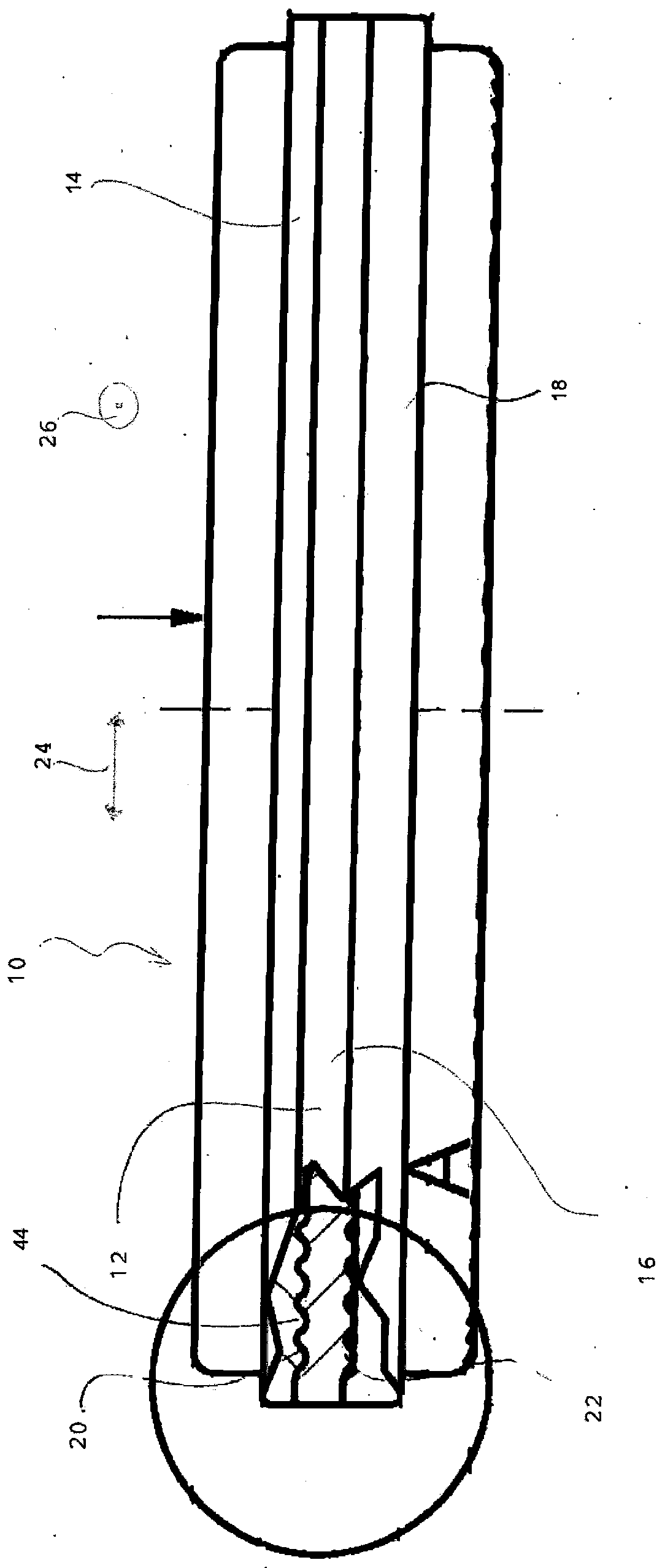

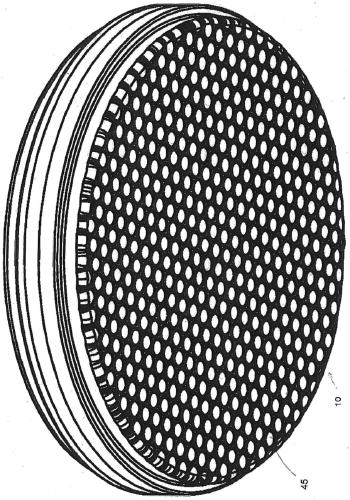

[0067] exist figure 1 and 2 The milling blank 10 shown in is disk-shaped in a manner known per se and has a diameter of approximately 100 mm. The milled blank 10 has a height of 20 mm.

[0068] The milled blank also has, in a manner known per se, a surrounding raised edge 12 for clamping in a corresponding holder of a milling machine.

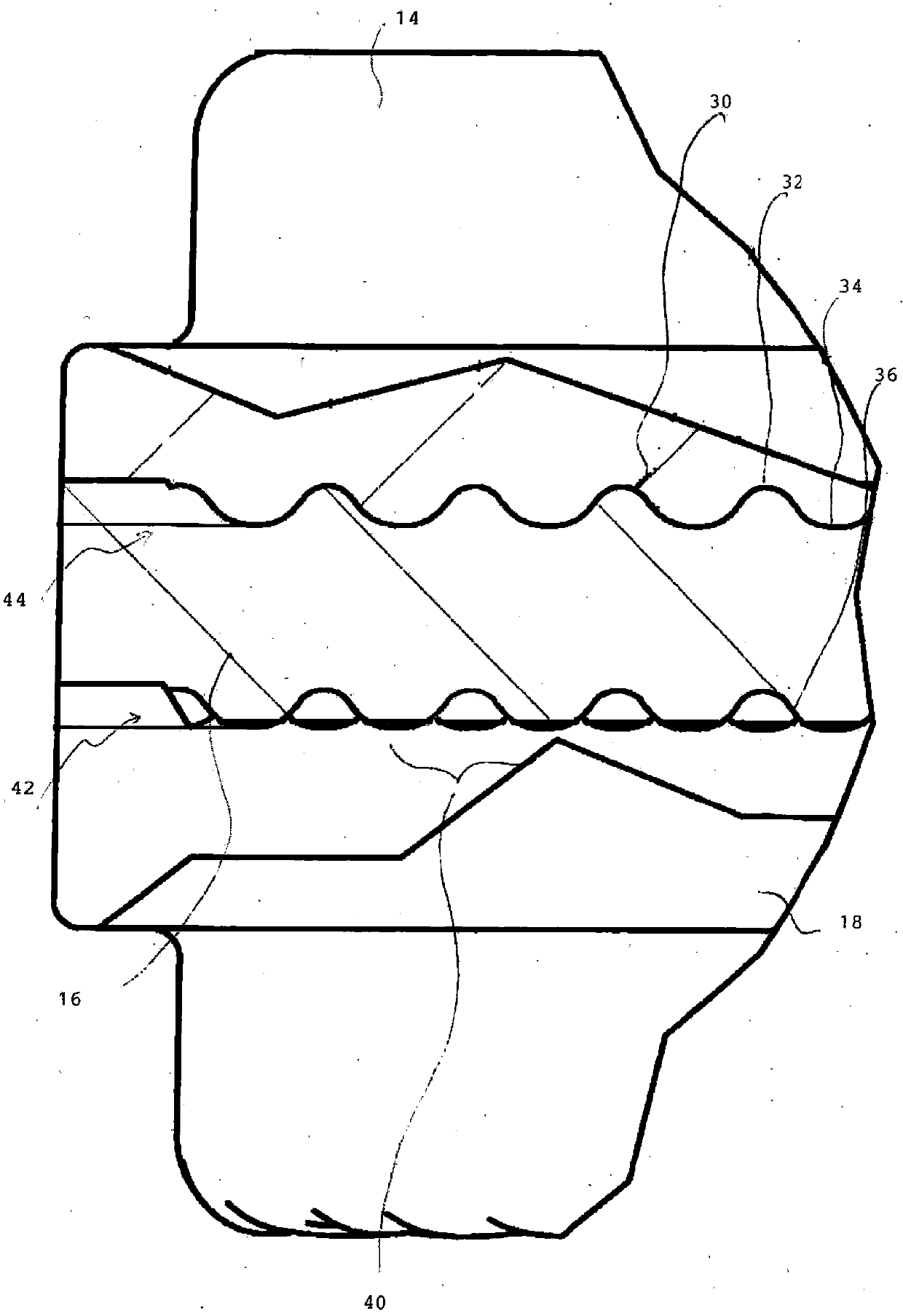

[0069] In the embodiment shown, the milled blank has three layers, namely an enamel layer 14 , an intermediate layer 16 and a dentin layer 18 .

[0070] Between the three layers 14 to 18 there is a transition zone in each case, a transition zone 20 between the enamel layer 14 and the intermediate layer 16 and a transition zone 22 between the intermediate layer 16 and the dentin layer 18 .

[0071] Each transition zone 20 and 22 has a specific transition geometry according to the invention, which extends three-dimensionally and according to the invention has circular surfaces 30 pointing in both directions of extension, as referenced below ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com