Clutch mechanism of electronic lock cylinder

A clutch mechanism, electronic lock technology, applied in building locks, building structures, non-mechanical transmission-operated locks, etc., can solve the problems of waste of resources, cumbersome door closing, inconvenient operation, etc., to ensure the effectiveness of use, The effect of improving safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

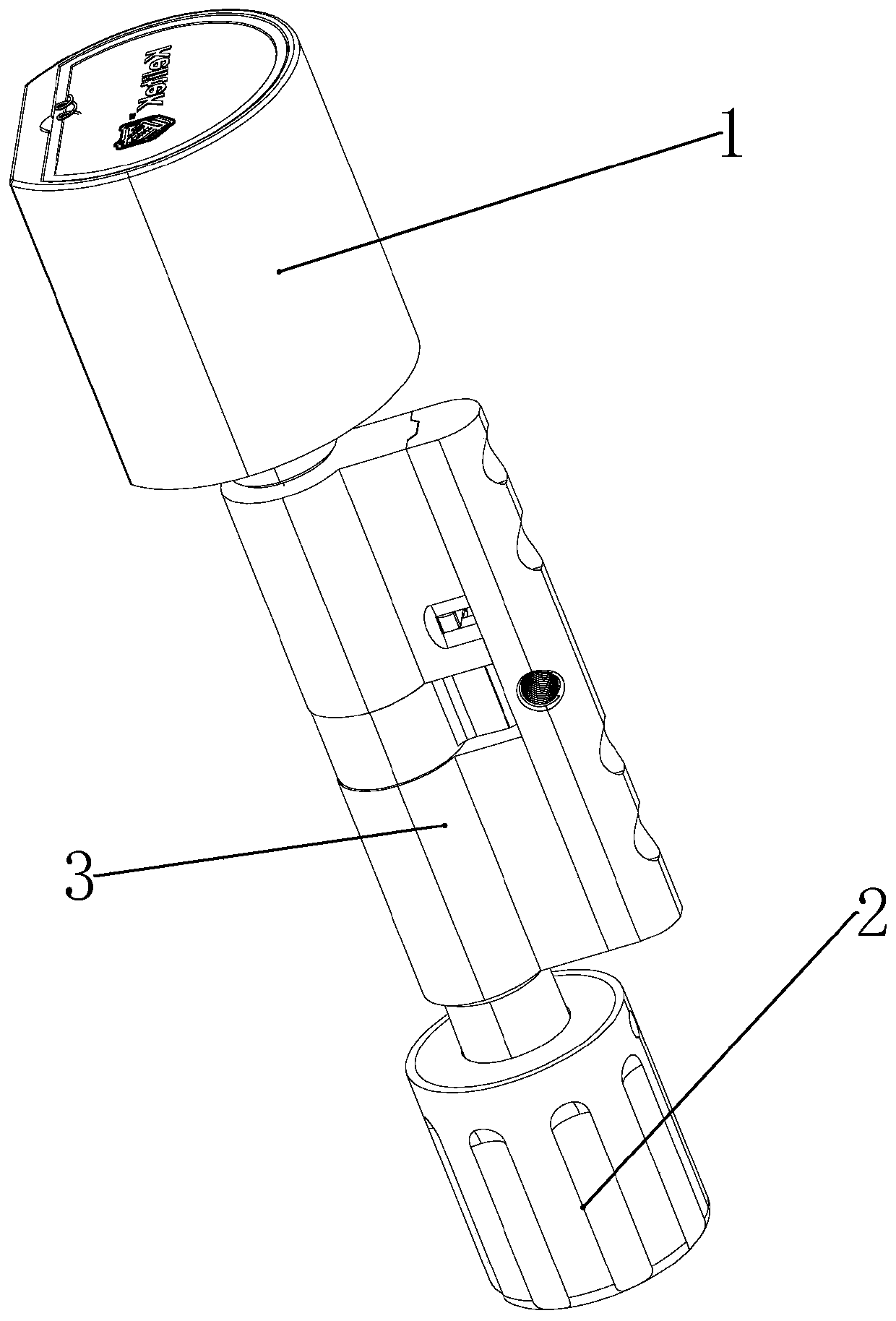

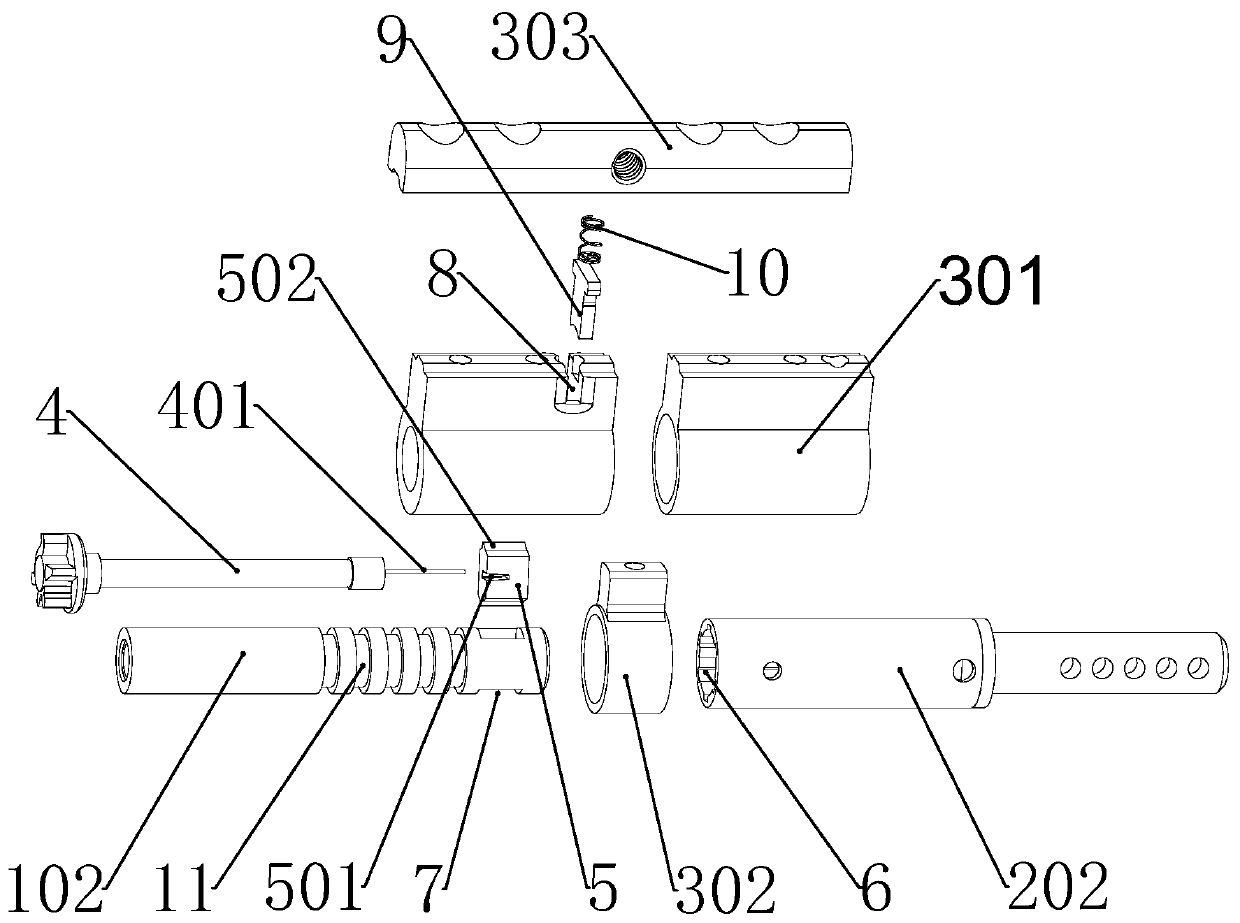

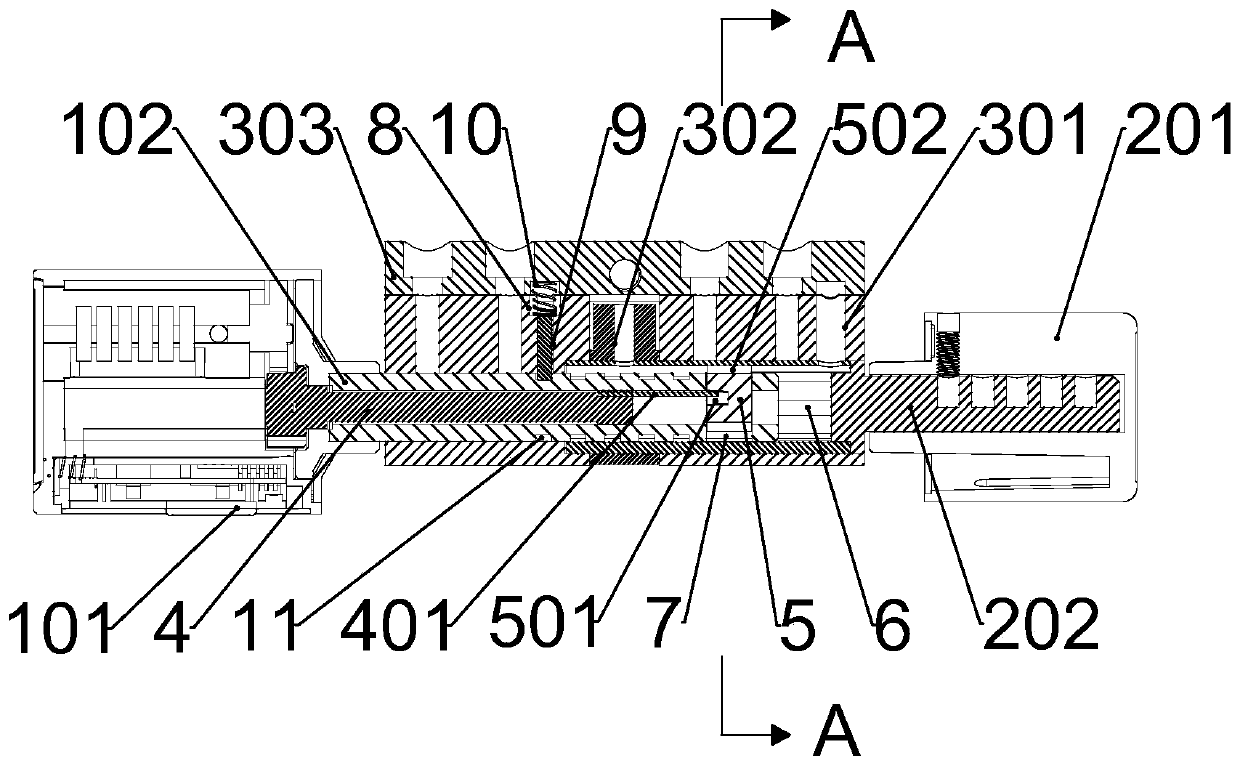

[0026] This embodiment discloses a kind of, such as Figure 1-6As shown, a clutch mechanism of an electronic lock cylinder includes a front handle assembly 1 assembled in the axial direction, a rear handle assembly 2 and a lock cylinder body 3 between them. The front handle assembly 1 includes a front The handle 101, the front main shaft 102 that rotates synchronously with the front handle 101, the rear handle assembly 2 includes the rear handle 201 and the rear main shaft 202 that rotates synchronously with the rear handle 201, the rear main shaft 202 is sleeved on the front main shaft 102, A clutch mechanism is arranged inside the front main shaft 102, and the clutch mechanism includes a lock core shaft 4 and a claw 5 that are forward and reverse relative to the front main shaft 102. The toggling lever 401 is made of steel wire with certain elasticity and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com