Hand-digging pipe-jacking butt joint connection structure and construction method thereof

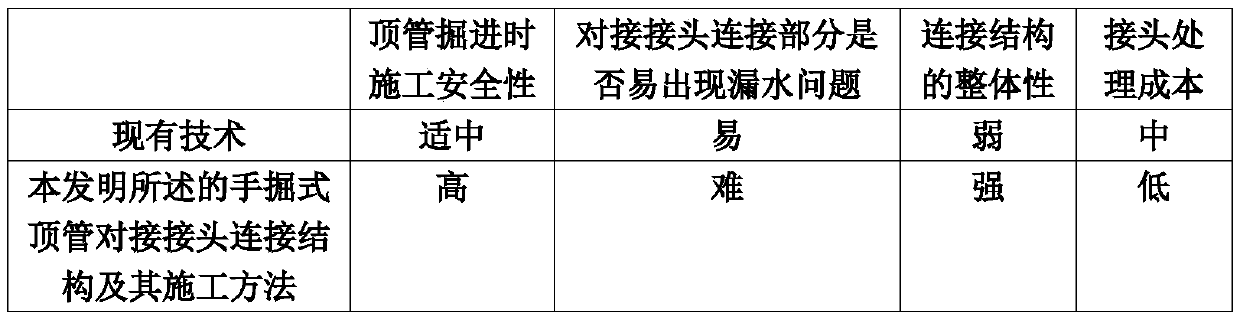

A technology of butt joints and connection structures, which is applied in the direction of pipes/pipe joints/fittings, pipeline laying and maintenance, mechanical equipment, etc., and can solve the problems of easy error, operational impact, and poor integrity of the intermediate butt joint connection parts, and achieve Overcoming the problem of water leakage, convenient and safe construction, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

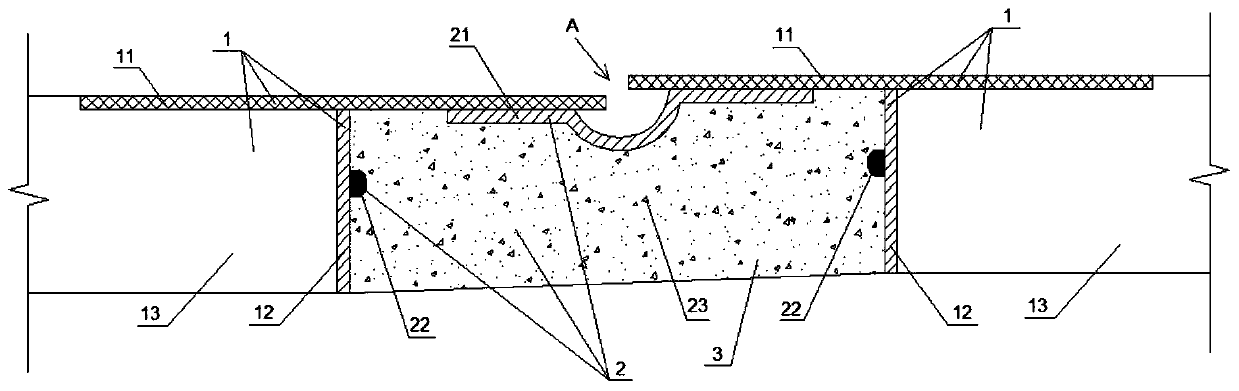

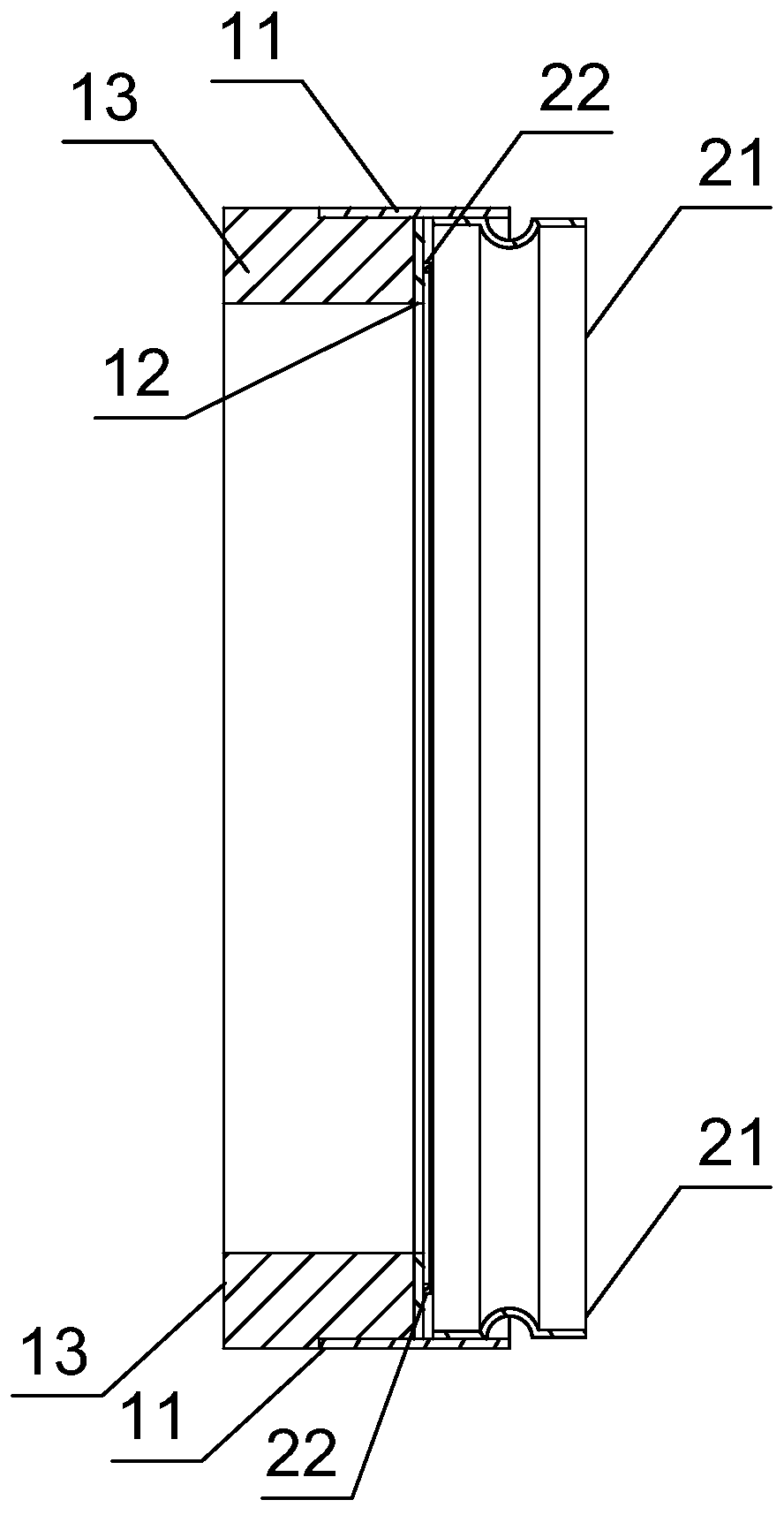

[0037] Referring to the accompanying drawings, it can be seen that the hand-excavated pipe jacking butt joint connection structure includes a prefabricated structure 1 and a cast-in-place structure 2. The pipe joint 13 is docked in the middle; the present invention performs soil cutting and advanced support on the prefabricated structure 1 to increase structural stability and improve docking accuracy;

[0038] The cast-in-place structure 2 includes an Ω steel plate 21, a water-stop structure 22 and structural concrete 23; the Ω steel plate is used to solve problems such as water leakage caused by staggered platforms;

[0039] The Ω steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com