A tunnel advance support type locking foot anchor structure and its construction method

A technology of locking foot bolts and advanced support, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., and can solve the problems that the welding position of the end of the bolt exceeds, cannot meet the support requirements, and the welding labor intensity is high. , to achieve the effect of eliminating harmful gases, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

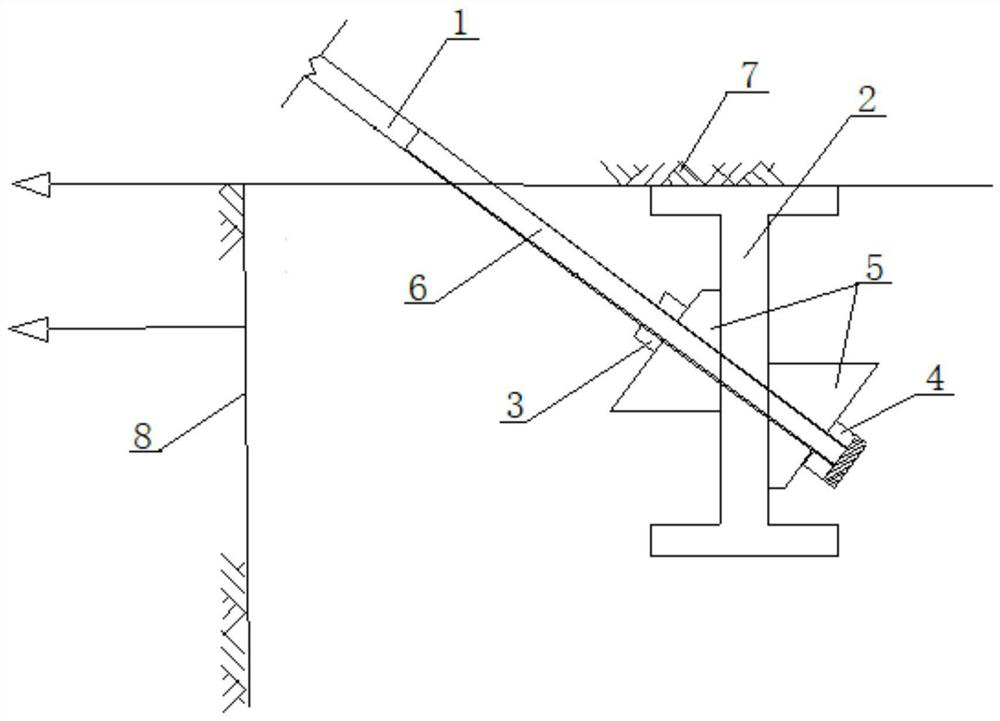

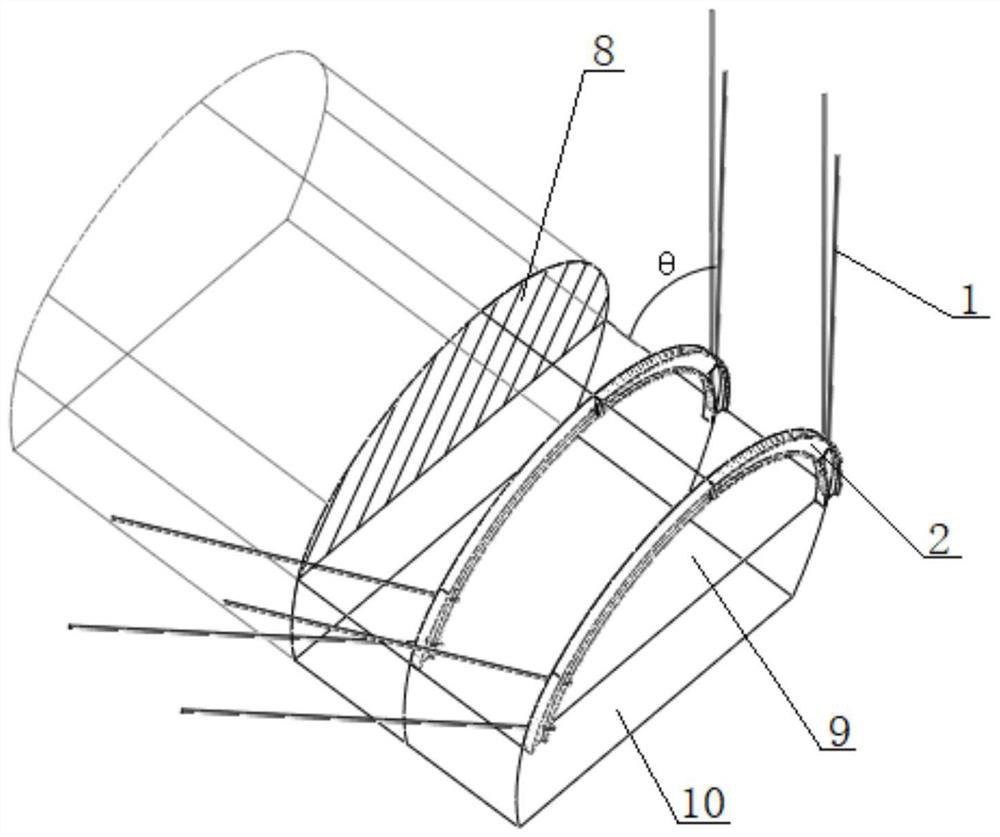

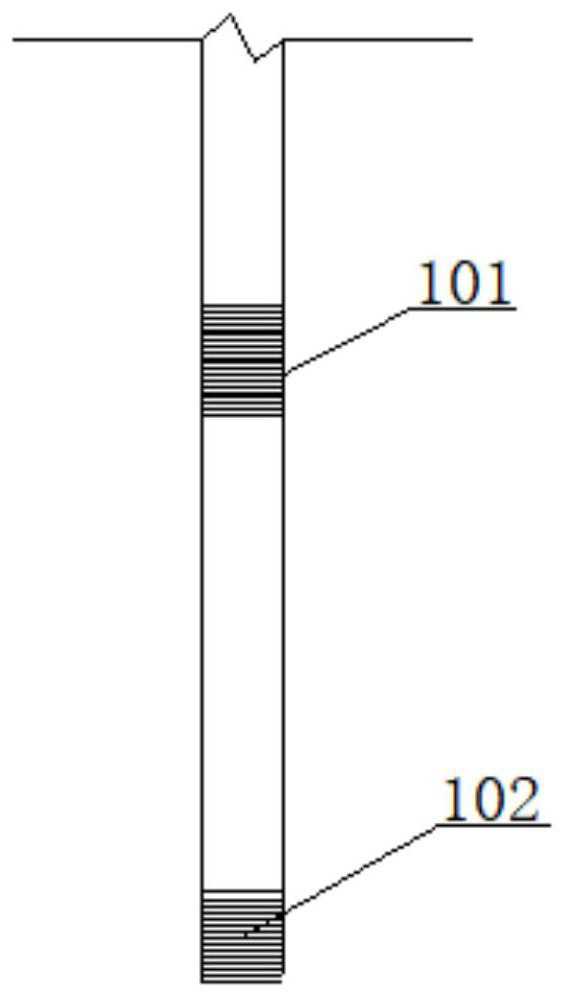

[0030] see Figure 1 to Figure 4 , a tunnel advance support type locking foot anchor structure, comprising a locking foot anchor 1 and an upper section steel arch 2. The upper profiled steel arch 2 includes flanges 201 at both ends and a web 202 in the middle, the web 202 is provided with several reserved holes 203, and the surrounding rock is provided with a plurality of drill holes corresponding to the reserved holes 203. hole, the radius of the reserved hole 203 is slightly larger than that of the locking foot bolt 1, and the locking foot bolt 1 is inserted into the corresponding drill hole through the top of the reserved hole 203; 2 before layout.

[0031] see Figure 1 to Figure 4 Specifically, the reserved holes 203 on the web 202 are arranged at a distance of 0.6m-0.8m, that is, one is arranged every 0.6m-0.8m.

[0032] see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com