LED light source assembly and high-power lamp using LED light source assembly

A technology of LED light source and LED light strip, which is applied in the direction of semiconductor devices, light sources, electric light sources, etc. of light-emitting elements, which can solve the problems of high price, large volume and heavy weight of LED lights, and solve the problem of heat dissipation and avoid volume increase , The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

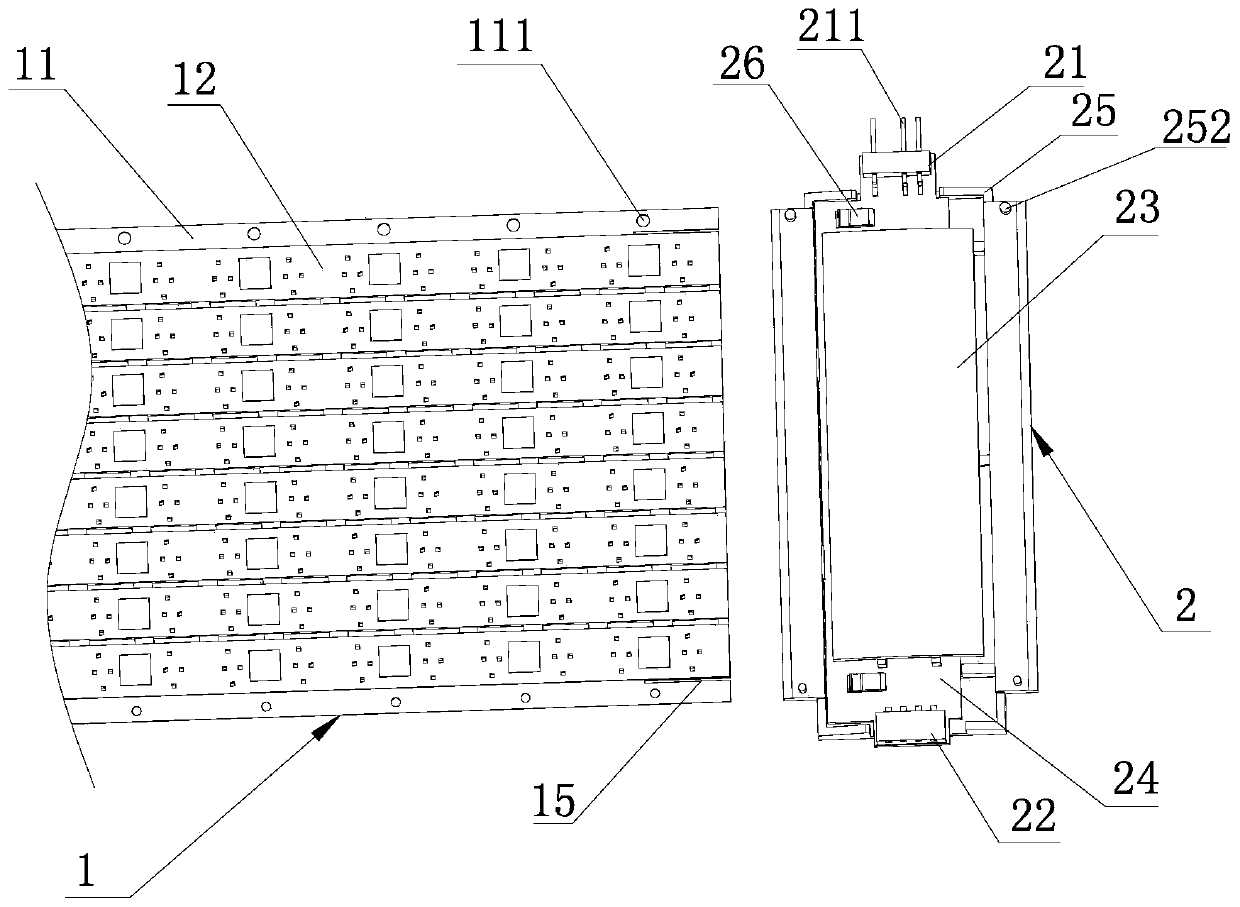

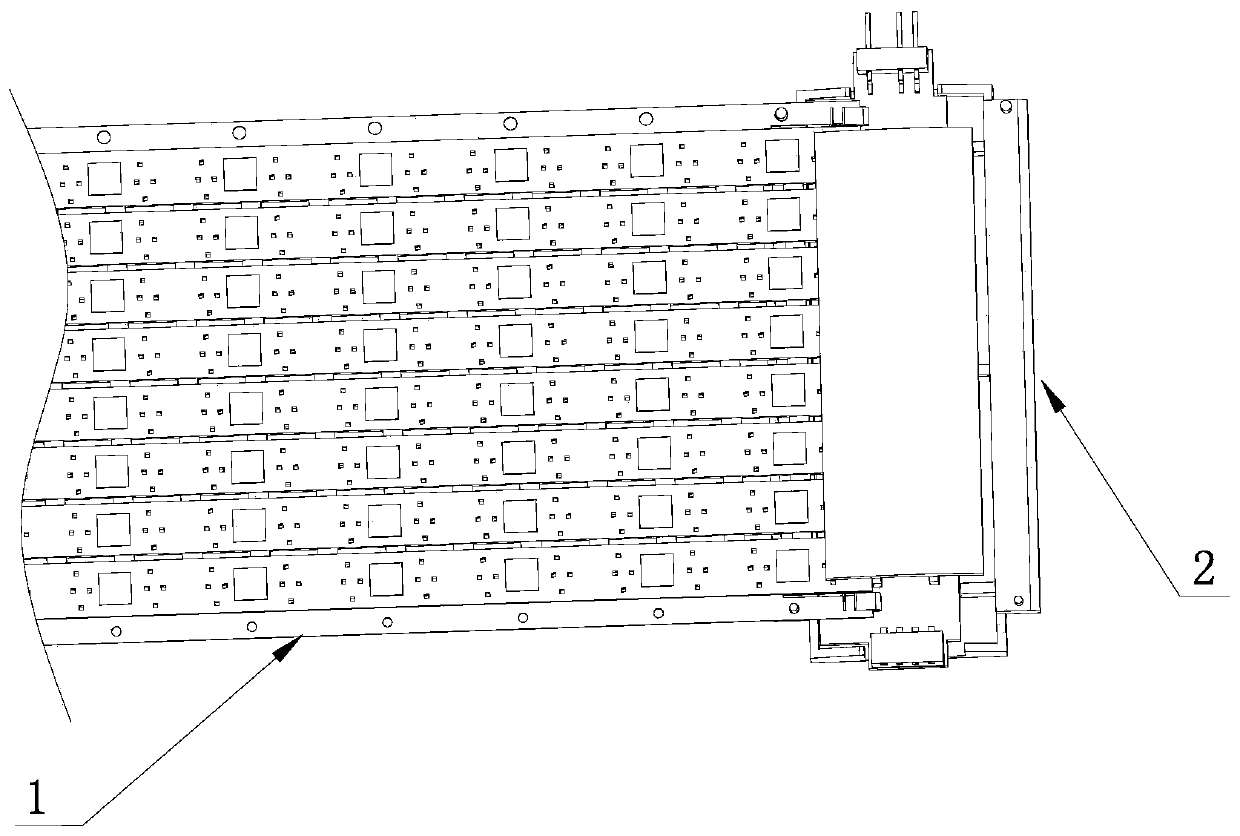

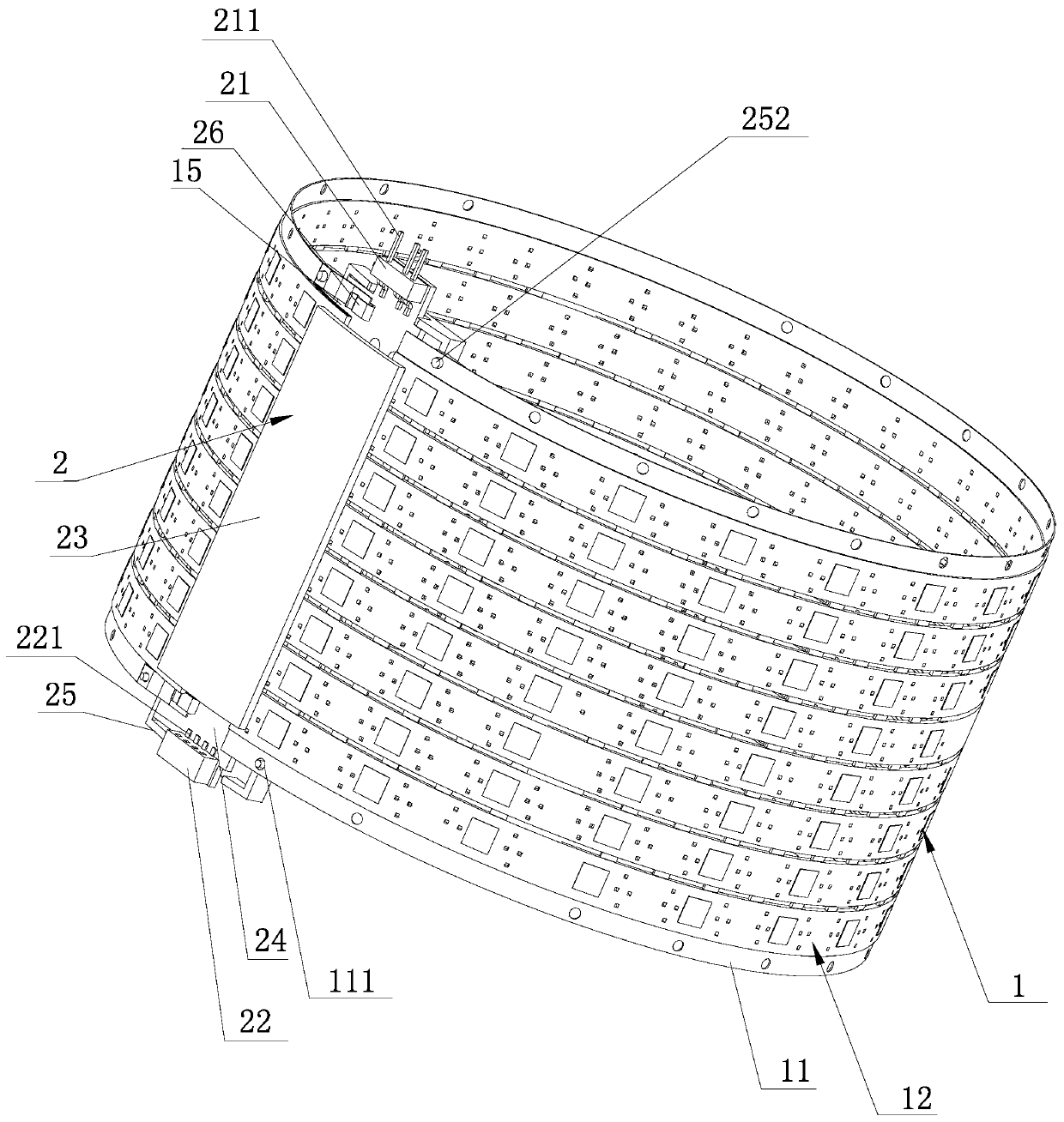

[0038] A kind of LED light source assembly proposed in this embodiment, such as Figure 1 to Figure 8 As shown, it includes an LED light source board 1 and an electrical connector 2. The LED light source board 1 has a bar-shaped structure. The LED light source board 1 has two electrodes 11 arranged along the length direction and parallel to each other. One end of the electrical connector 2 has a plug The needle assembly 21 and the other end has a socket assembly 22, so that one end of the length direction of the LED light source board 1 is connected to one side of the electrical connector 2, and the other end of the length direction of the LED light source board 1 is connected to the electrical connector 2 after the LED light source board 1 is curled. The other side of the connector 2 is connected, and the pin assembly 21 is electrically connected to one electrode 11 close to it, and the socket assembly 22 is electrically connected to the other electrode 11 close to it, forming...

Embodiment 2

[0046] This embodiment proposes a high-power lamp using the LED light source assembly of Embodiment 1, such as Figure 9 to Figure 18 As shown, it includes a lamp cap 3, a lamp body 4, a driving power supply 5 arranged in the lamp body 4, three LED light source assemblies G, a top layer ring 7, a top layer light source board 8, an annular mask 9, the lamp cap 3 and the lamp The narrow mouth of the body 4 is connected, the top layer light source board 8 is installed on the top of the top layer ring 7, the annular mask 9 is covered outside the top layer light source board 8 and connected with the top of the top layer ring 7, and passes between two adjacent LED light source assemblies G The connecting ring 6 is connected, the top of the wide mouth of the lamp body 4 is connected to the bottom of the bottom LED light source assembly G, the top layer ring 7 is connected to the top of the top LED light source assembly G, and the bottom LED light source The socket assembly 22 in the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap