High-strength square sealing head processing technology

A processing technology and high-strength technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of large size, easy deformation, easy deformation of the head, etc., to achieve long service life, small overall deformation and high quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

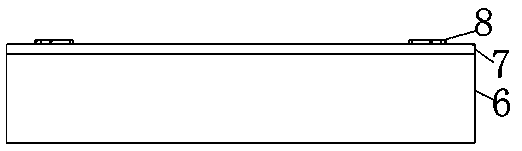

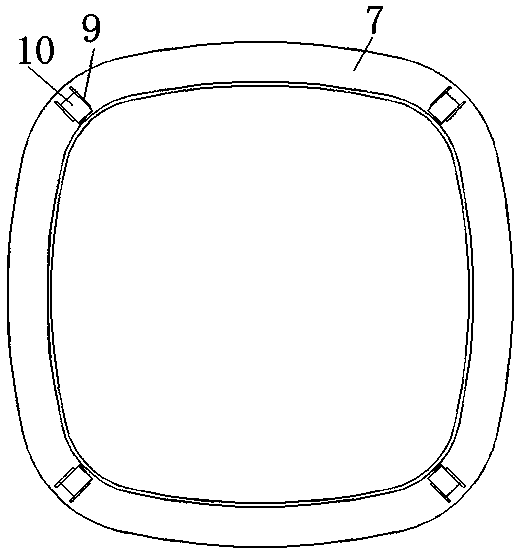

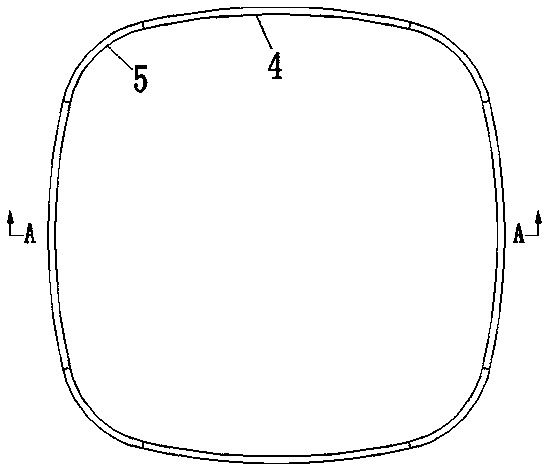

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a kind of high-strength square head processing technology described in the present invention, it comprises the following steps,

[0027] (1) Make the head forming mold;

[0028] (2) cutting;

[0029] (3) Hot stamping: one-time molding to make the main body of the square head;

[0030] (4) Groove and water-cooling elimination: fix the main body of the square head on the special tooling, then inject water into the main body of the square head as a whole, use the magnetic wheel cutting machine to bevel, and then use the edge tearing machine to bevel the angle;

[0031] (5) Groove grinding, surface pickling, partial grinding, overall surface treatment, and overall acceptance;

[0032] In step (3), the main body of the square head includes a four-sided arc-shaped botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap