Method for identifying oil fume of range hood and range hood

A range hood and oil fume technology, which is applied in the direction of oil fume removal, character and pattern recognition, heating methods, etc., can solve the inaccurate recognition results of oil fume image data frames, the inability to accurately control kitchen appliances, and the inability to correctly calculate key feature smoke Issues such as the actual amount of change, to achieve the effect of ensuring quality and using habits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

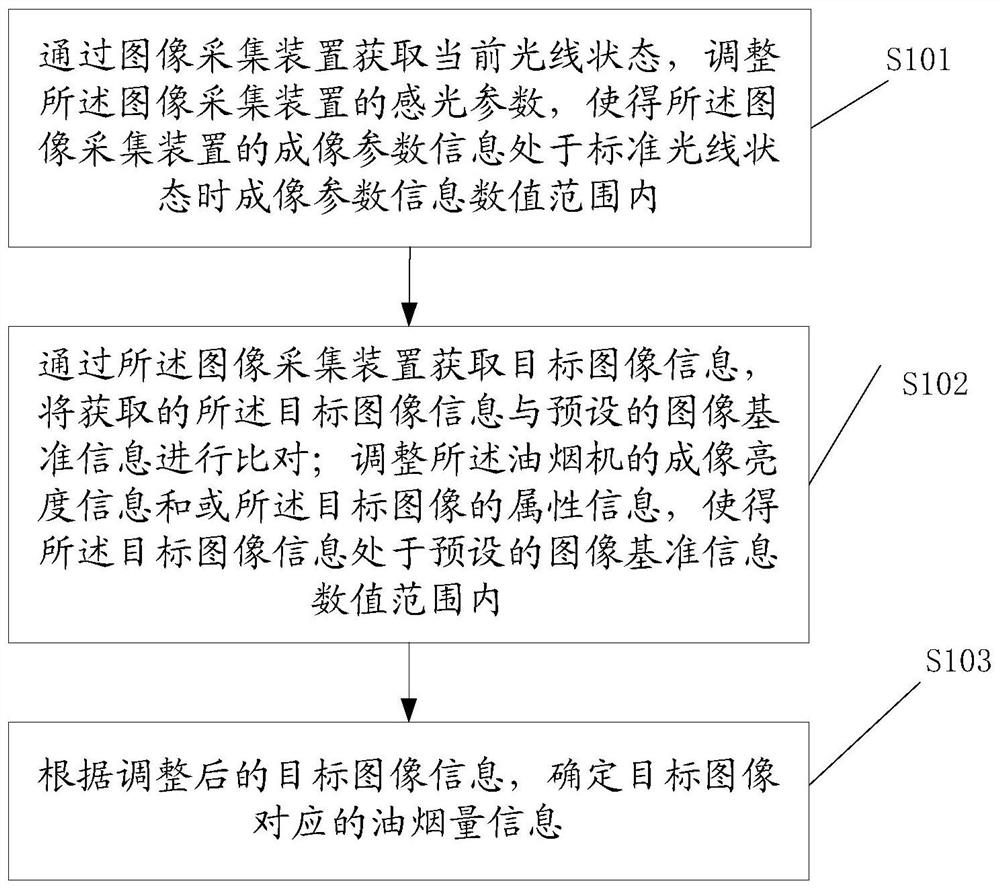

[0099] Such as Figure 4 As shown, in order to solve the impact of ambient light on image recognition, parameters such as brightness, grayscale, and color that may have a greater impact on recognition are selected. In sunny days, no direct light, and bright environments, the image effect of this embodiment is processed. The numerical range of the correct recognition result is used as the parameter benchmark, and the brightness value, color, gray value and other parameters obtained by the camera at the current moment are compared with the parameter benchmark, and when the value is not within the benchmark range, adjust the relevant parameters until the value falls. Within the reference range, the image processed by the above process is re-identified to correspond to the oil fume information, and the process is as follows:

[0100] 1. Adjust the photosensitive parameters of the hue head based on the brightness, grayscale, and color parameter benchmarks of the pre-established sta...

Embodiment 2

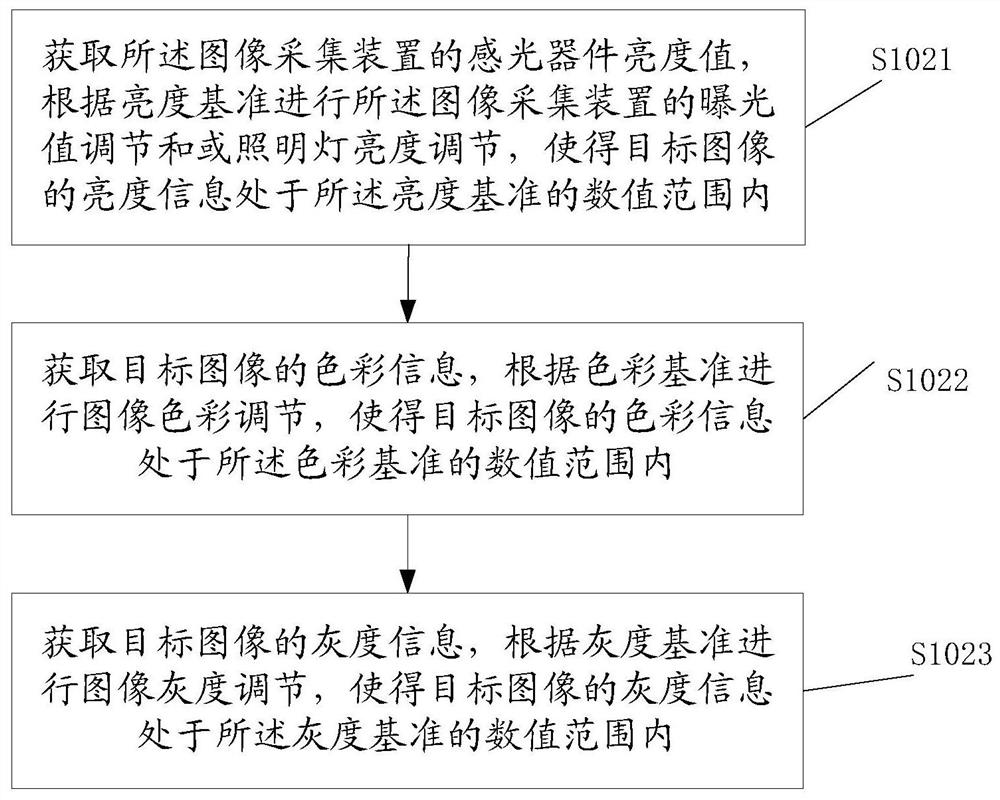

[0107] This embodiment illustrates the process of image brightness adjustment:

[0108] Upgrade the conventional lighting device of the range hood to a lighting with adjustable brightness value, and choose a lens with a large enough light input for the camera recognition module so that it can have better adaptability in the case of excessive light or too dark light . The brightness adjustment process in the image recognition process is as follows: Figure 5 As shown, first obtain the brightness value of the photosensitive device of the camera. If the brightness value is lower than the reference range, it means that the current ambient light is dark. At this time, the exposure time of the lens is increased step by step. The power consumption of the camera increases, and the heat of the camera makes the current noise of the captured image larger. Therefore, it is necessary to set the exposure level threshold, which can allow the camera to freely adjust the exposure time without...

Embodiment 3

[0110] This embodiment illustrates the process of image color adjustment:

[0111] After the above brightness adjustment, the brightness value of the image data collected by the cooker hood in real time has been adjusted to the reference range, but no matter how high or low the exposure parameters of the camera are adjusted or the brightness value of the captured image is directly adjusted, the image quality will be affected. And almost all image recognition technologies are based on the grayscale image after image data frame binarization, so the image quality loss caused by brightness adjustment must be restored before the grayscale image processing. The camera-side and color-related parameters include image contrast, hue, and saturation. Its adjustment process is as follows Figure 6 Shown: first obtain the image contrast, chroma and saturation values of the color card area, and compare with the established color reference, so that the three parameters of the color card a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com