High stability liftable resistance furnace suitable for fire test of 3D frame structure

A frame structure and high-stability technology, applied in the field of high-stability liftable resistance furnaces, can solve problems such as inconvenient hanging of heat preservation devices, difficulty in continuing to heat up electric furnaces, sinking of heat preservation devices, etc., and achieve good synergistic deformation effects and increased Out-of-plane stability and torsional stability, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solutions provided by the present application will be further described below in conjunction with specific embodiments and accompanying drawings. The advantages and features of the present application will become clearer in conjunction with the following description.

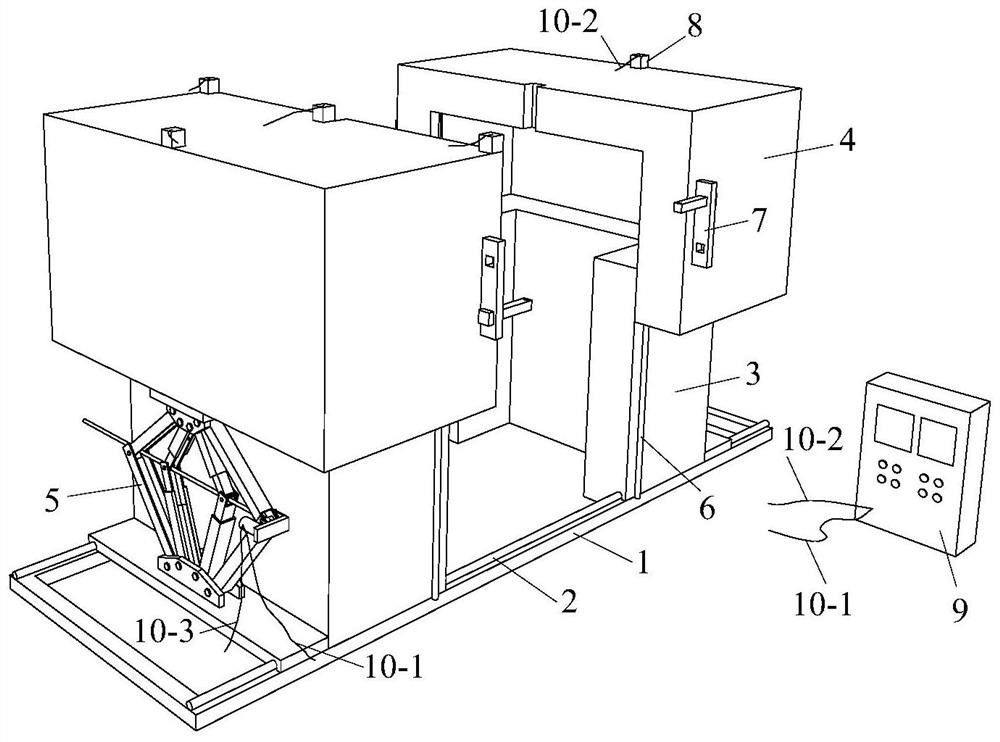

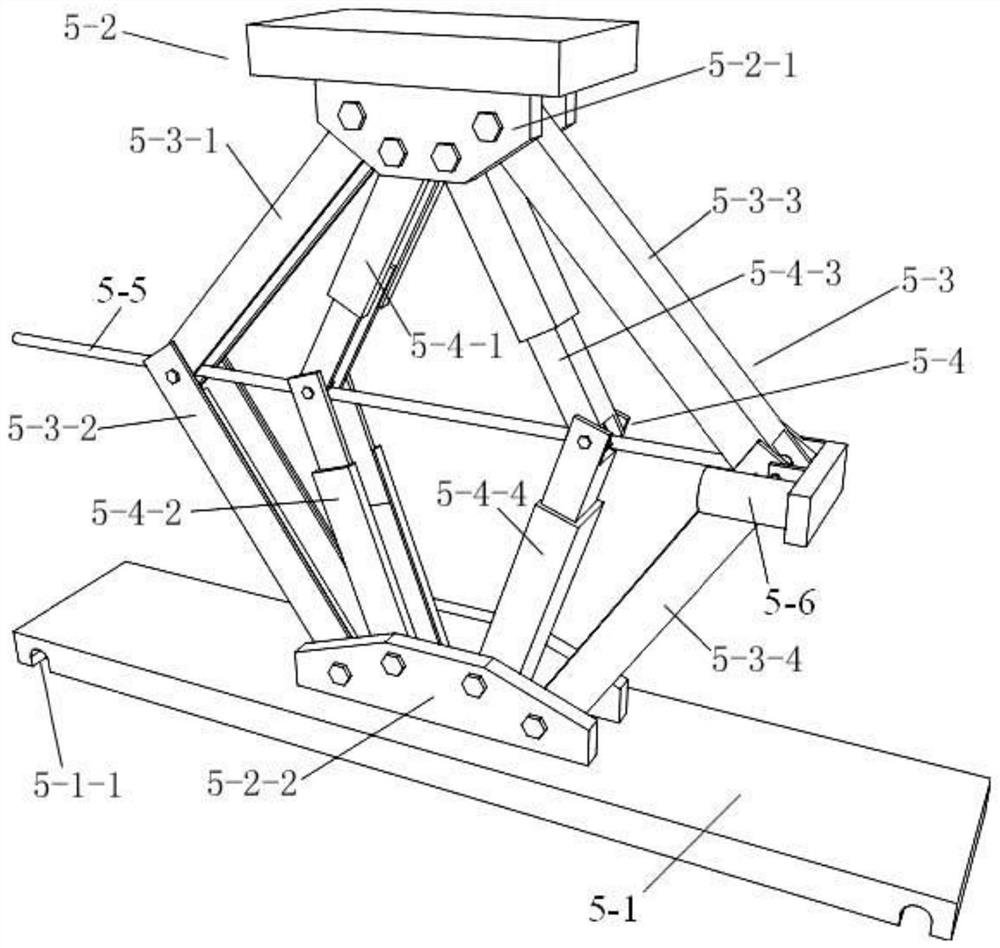

[0053] Such as Figure 1 to Figure 4 As shown, a high-stability liftable resistance furnace suitable for three-dimensional frame structure fire test includes a base 1, a first guide rail 2, a lower furnace body 3, an upper furnace body 4, a lifting control device 5, a high-frequency laser measuring Distance sensor 8 and control cabinet 9.

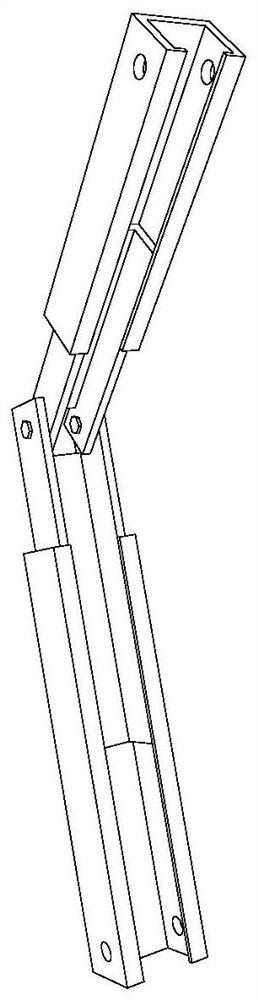

[0054] Wherein, the base 1 can adopt a frame structure, and the left and right sides of the frame structure are respectively equipped with a first guide rail 2; First rollers are installed in the bottom grooves of the second lower furnace body, and the first lower furnace body and the second lower furnace body are respectively installed on the two first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com