Controllable resistance furnace suitable for fire test of 3D frame structure

A technology of frame structure and resistance furnace, which is applied in the testing of machine/structural components, furnace, furnace type, etc. It can solve the problems of long time, hot gas exposure, lack of three-dimensional frame structure resistance furnace, etc., and achieve good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions provided by the present application will be further described below in conjunction with specific embodiments and accompanying drawings. The advantages and features of the present application will become clearer in conjunction with the following description.

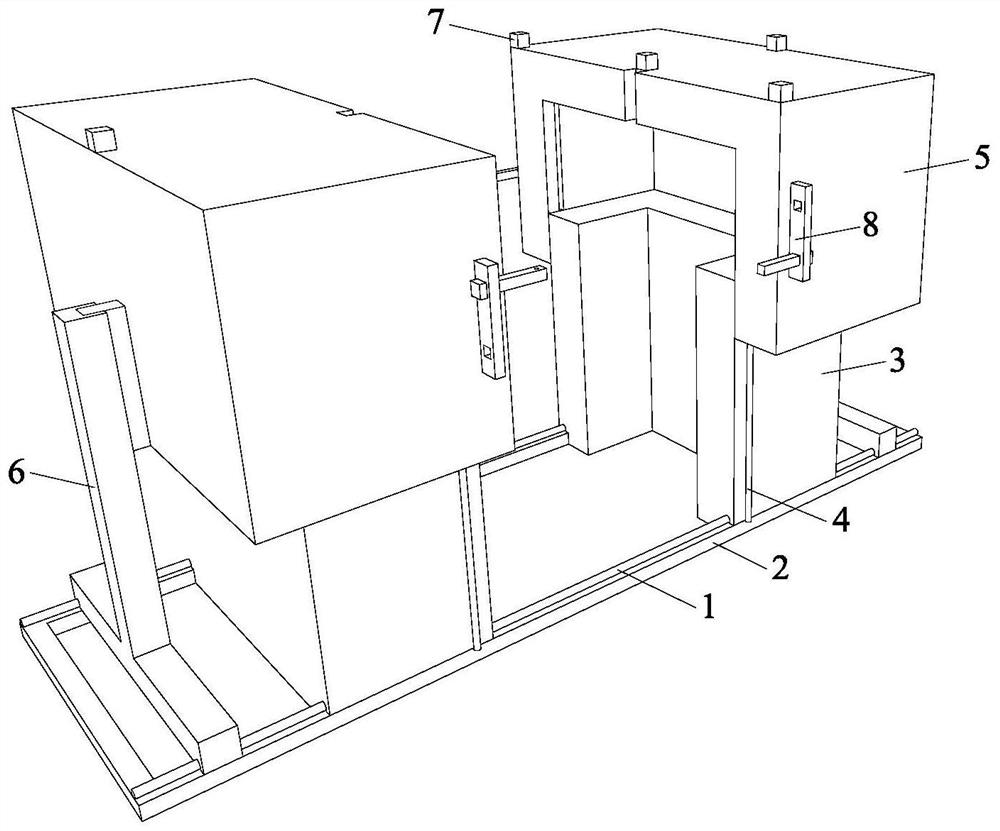

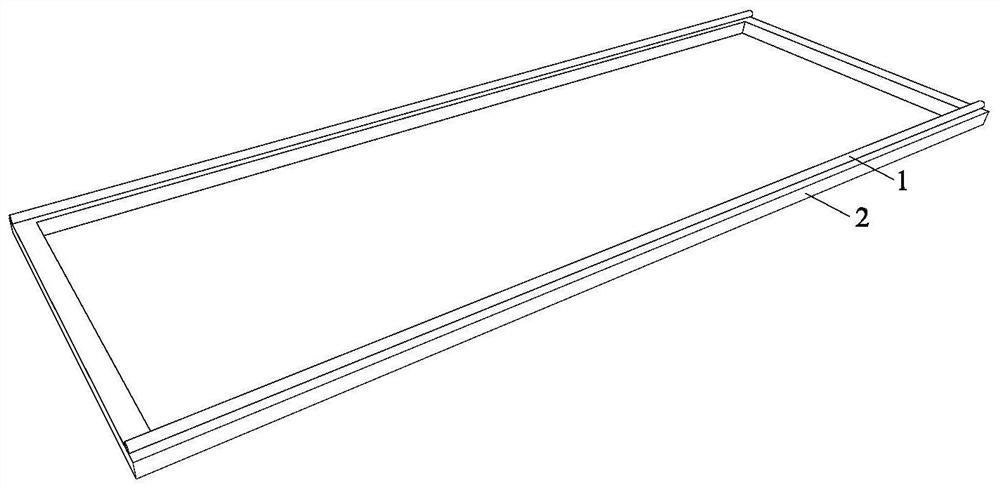

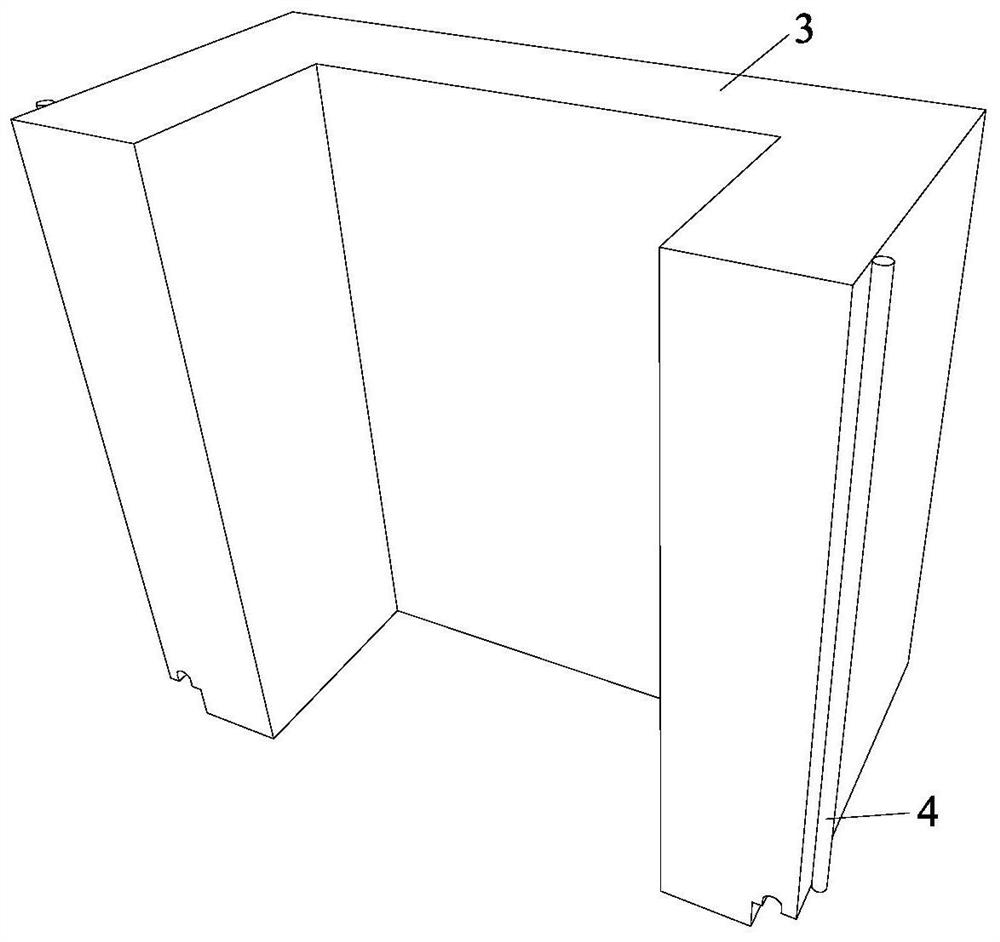

[0041] Such as Figure 1 to Figure 7 As shown, a controllable resistance furnace suitable for fire test of three-dimensional frame structure includes first guide rail 1, base 2, lower furnace body 3, upper furnace body 5, heating resistance wire, upper furnace body moving device 6, high Frequency laser ranging sensor 7 and control system.

[0042]Wherein, the base 2 can adopt a frame structure, and the front and rear frames of the frame structure are respectively equipped with a first guide rail 1; and the bottom of the second lower furnace body are equipped with first rollers, and the first lower furnace body and the second lower furnace body can be slidably installed on the two first gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com