An electronic detonator chip foot wire riveting device

A technology of electronic detonators and riveting devices, which is applied in the direction of offensive equipment, fuzes, weapon accessories, etc., can solve the problems of low riveting efficiency and difficult quality assurance, and achieve the effects of improving production efficiency, high degree of automation, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

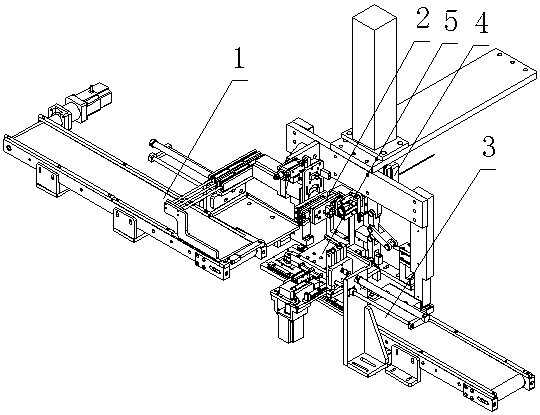

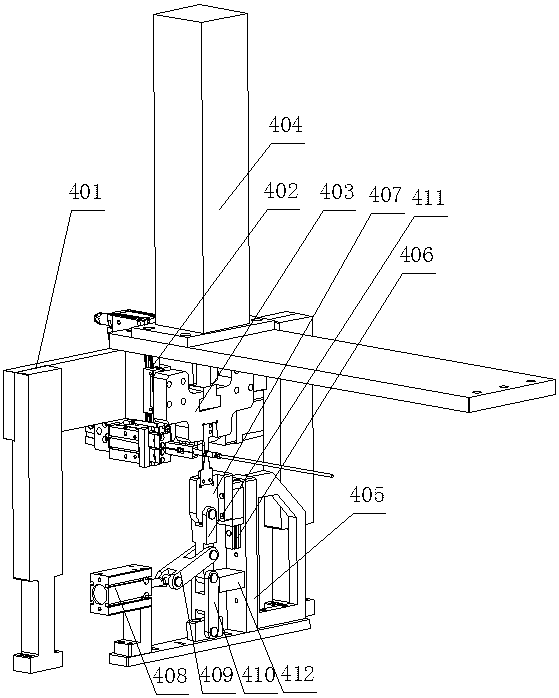

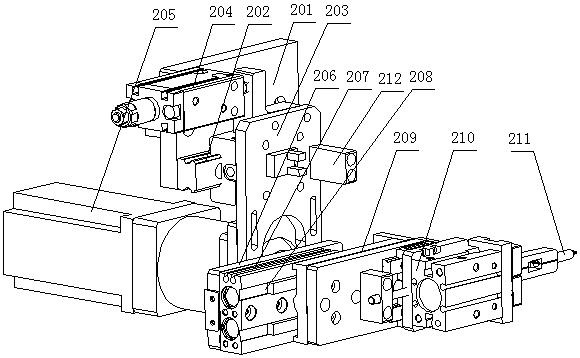

[0022] Such as figure 1 The shown electronic detonator chip pin line riveting device includes a feeding module 1, a riveting module 4, and a retrieving module 2 connected to the riveting module 4, and the material box (not shown in the figure) is moved from the feeding module 1 into the retrieving module. The transfer module 5 at the reclaiming position of the module 2, and the empty box recycling module 3 that removes the magazine from the transfer module 5 . Such as figure 2 As shown, the riveting module 4 includes a riveting frame 401, a first linear slide rail 402 connected to the top of the riveting frame 401, a riveting upper punching knife 403 slidingly connected to the first linear slide rail 402, a cylinder base and a riveting The top of the frame 401 is connected, the first cylinder 404 that the piston rod i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com