Ankle arthroplasty systems and methods

A technology for ankle joints, articular surfaces, applied in the field of surgical operating systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0164] The result can be as Figure 6B and 10B Formation of preparation surface 620 is shown. combine Figure 11A and 11B Fabrication surface 620 will be further shown and described.

[0165] Figure 11A and 11B A side elevational view, a cross-sectional view, and an enlarged cephalic frontal view, respectively, of the talus 420 with the talus base 410, talus burr holder 600, and burr 610 as shown in Figs. Figure 10A and 10B positioning shown. In addition to the slot for the keel 212 of the talar prosthesis 102, the shape of the preparation surface 620 is shown in more detail.

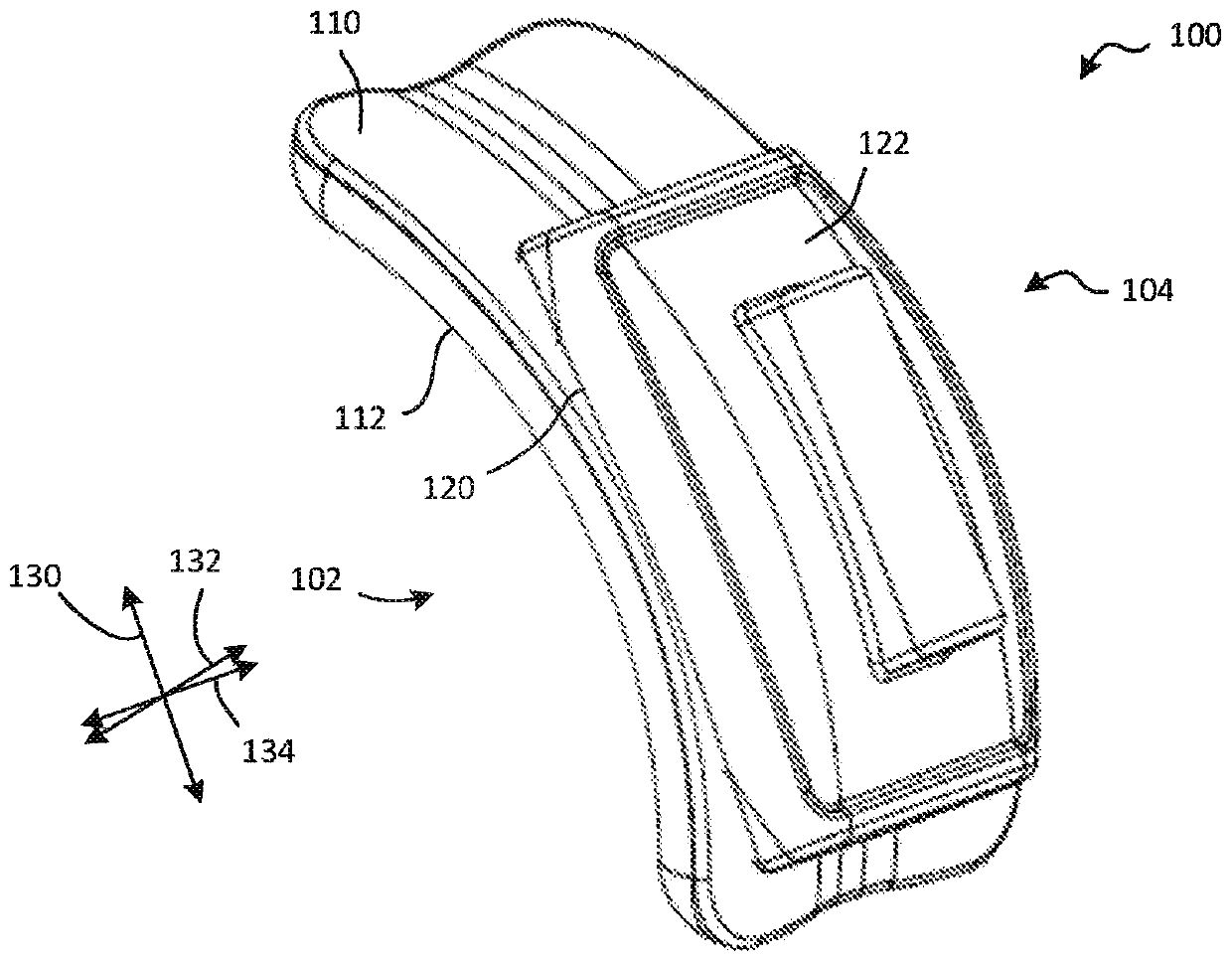

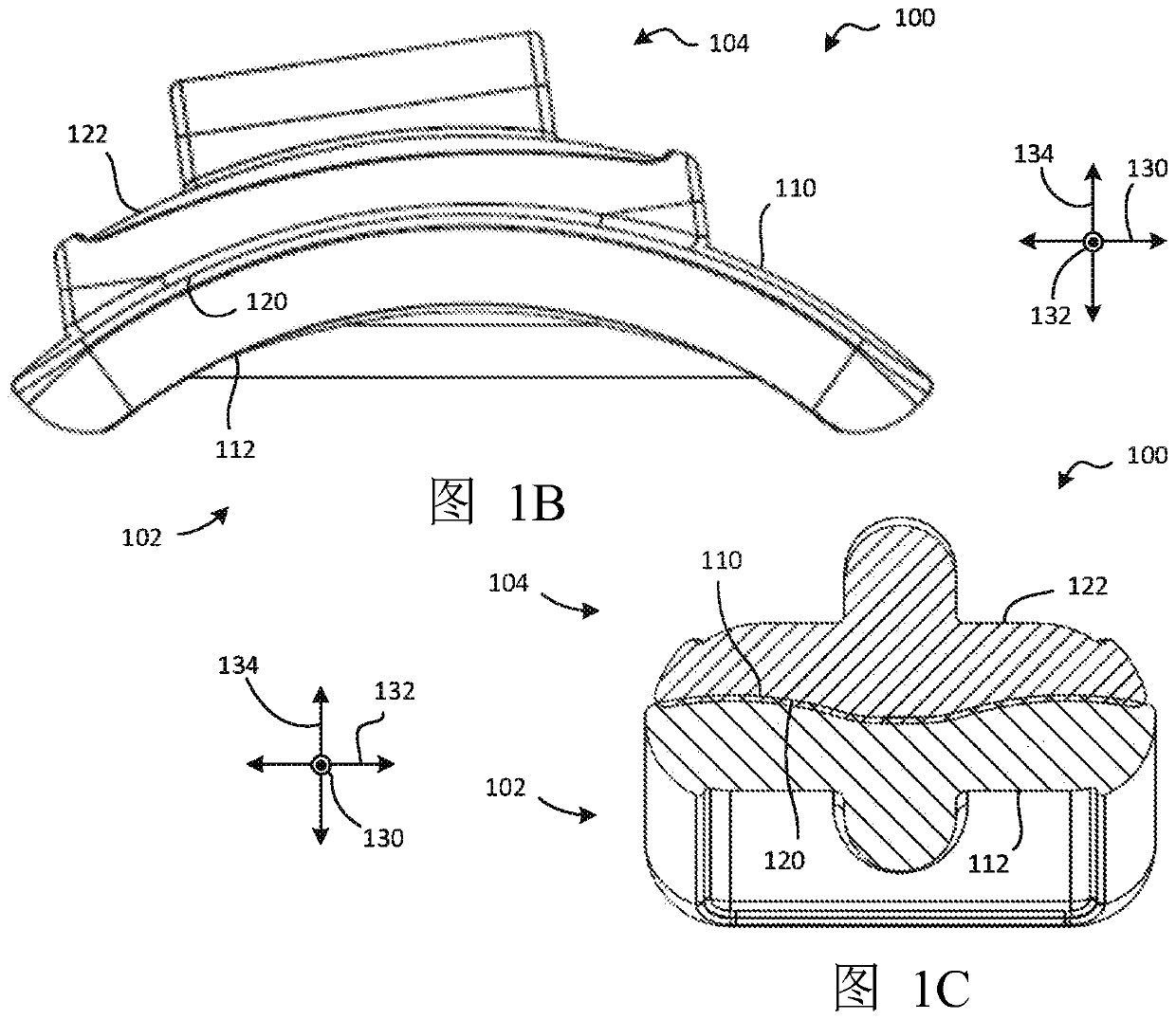

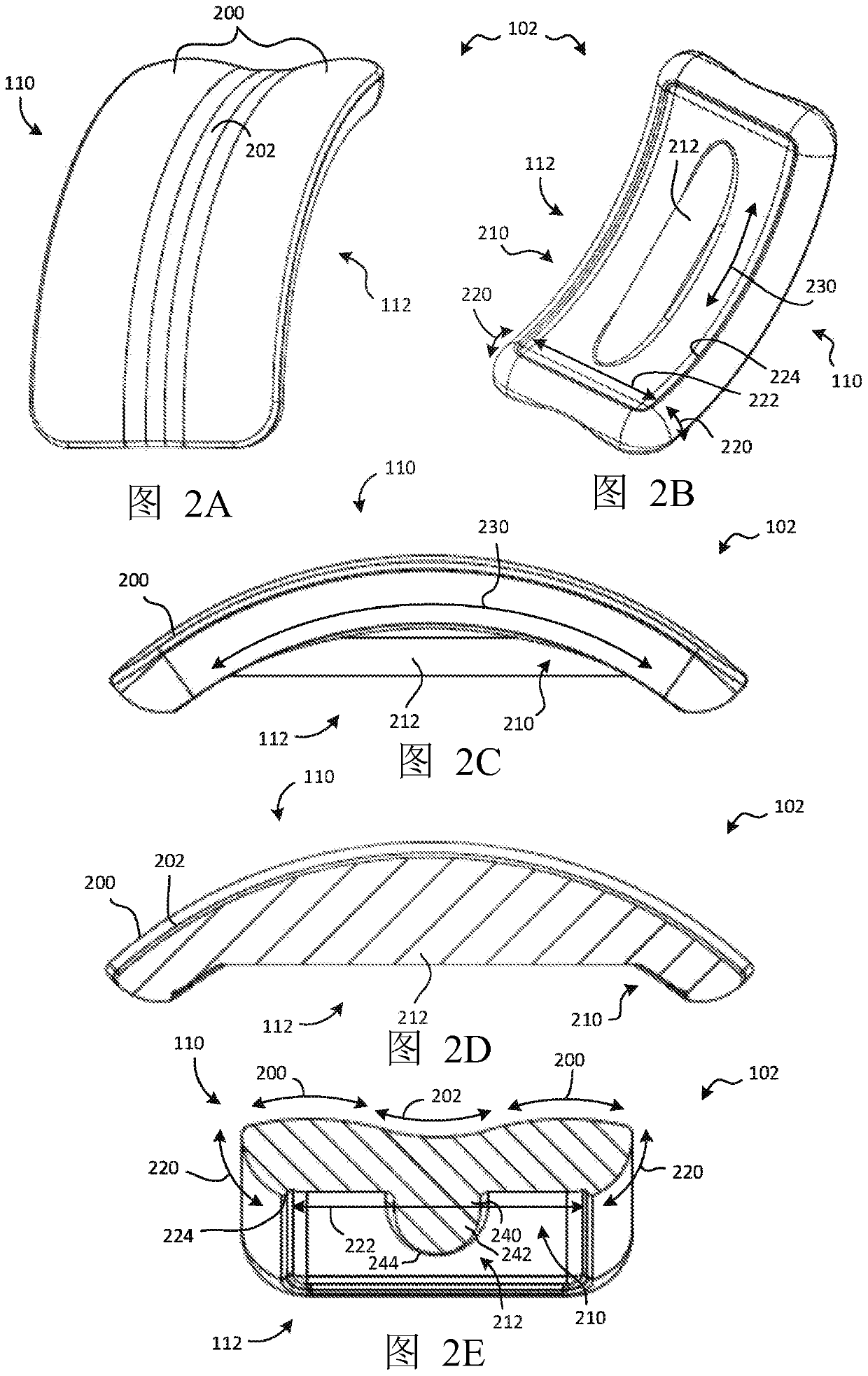

[0166] like Figure 11A As shown, the fabrication surface 620 may have a side cross-sectional shape in planes located in the anterior-posterior direction 130 and the cranio-caudal direction 134, the planes being the same as those shown in Figure 2C The side views of the talar prosthesis 102 shown are closely matched. The preparation surface 620 may have a convex anteroposterior curvature 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com