Numerical control machining combined machine for pin tumbler lock cylinders

A marble lock cylinder, combined machine technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of difficult to achieve automatic flow processing, unable to complete the transmission accurately, increase labor costs, etc., to achieve automatic processing, prevent The effect of self-rotation displacement and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

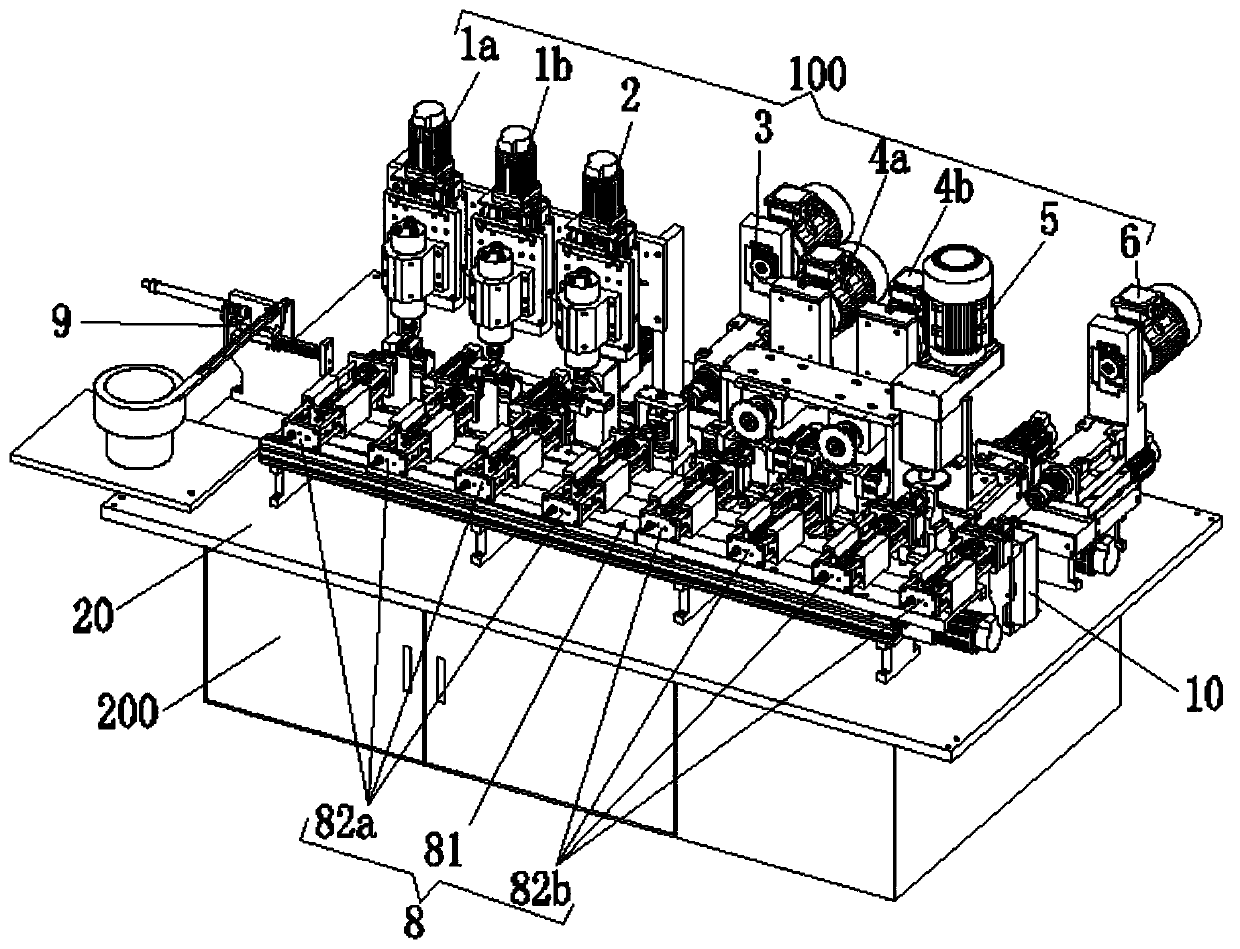

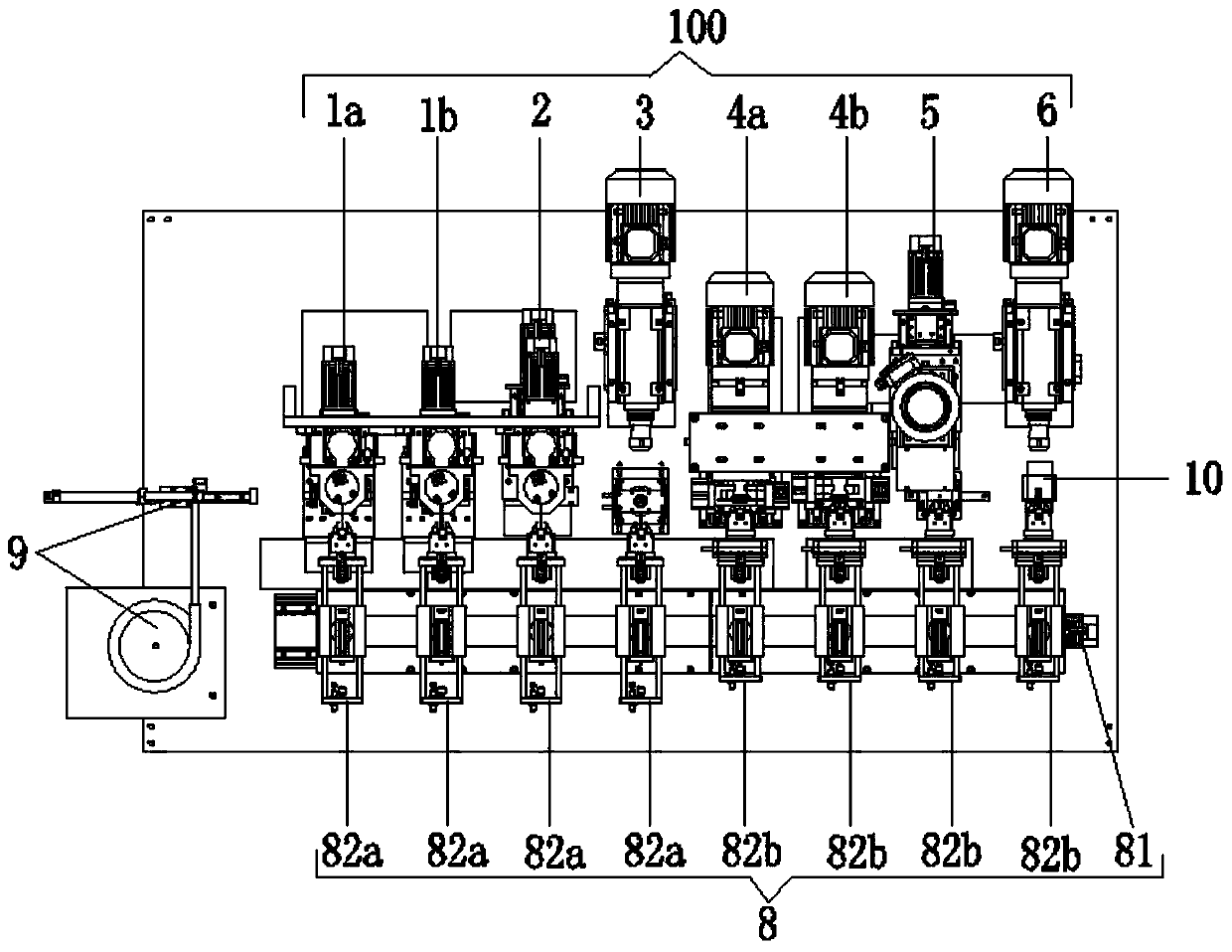

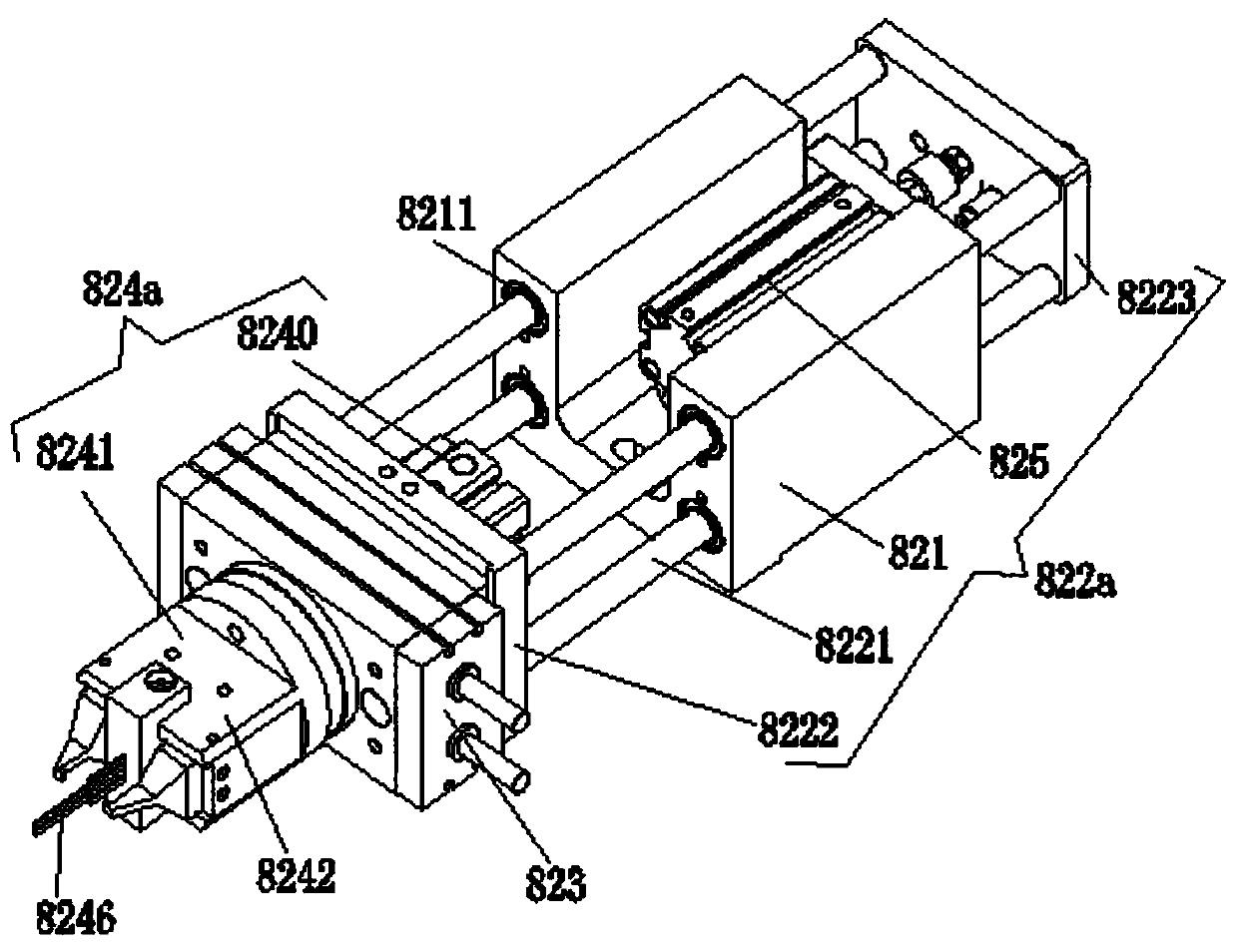

[0050] Such as Figure 1-27 As shown, a pin lock cylinder numerical control processing combination machine includes: a frame platform 20, and a processing unit 100 installed on the frame platform 20, a workpiece transmission device 8, a feeding device 9, and a discharging device 10; The bottom of the frame platform 20 is provided with a control box 200; the processing unit 100 is relatively distributed with the workpiece transmission device 8; the feeding device 9 and the discharging device 10 are respectively distributed at the two ends of the processing unit 100; The unit 100 is composed of a number of processing devices arranged in a linear manner, and each group of processing devices can independently complete the processing of a process; the workpiece transmission device 8 includes a number of transmission arms 82 installed on the seventh servo slide 81; The seventh servo slide 81 is installed on the frame platform 20; the number and arrangement of the transmission arms 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com