Quantitative injection device for drying agent processing

A technology of injection device and desiccant, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, which can solve the problems of reducing work efficiency and manpower consumption, and achieve the effect of reducing repeated loading operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

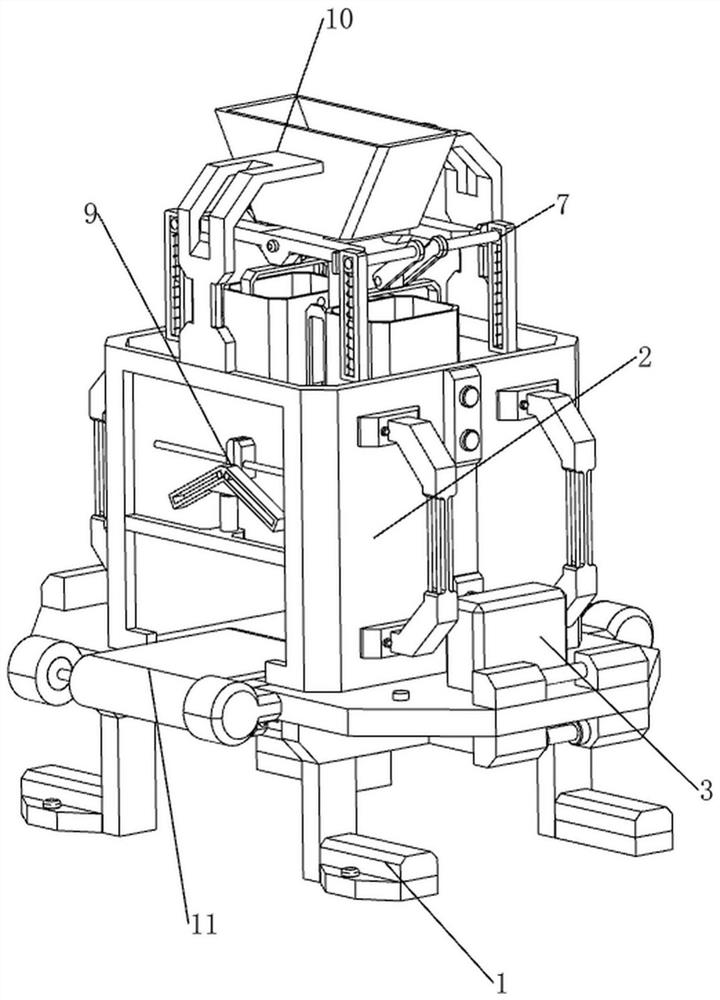

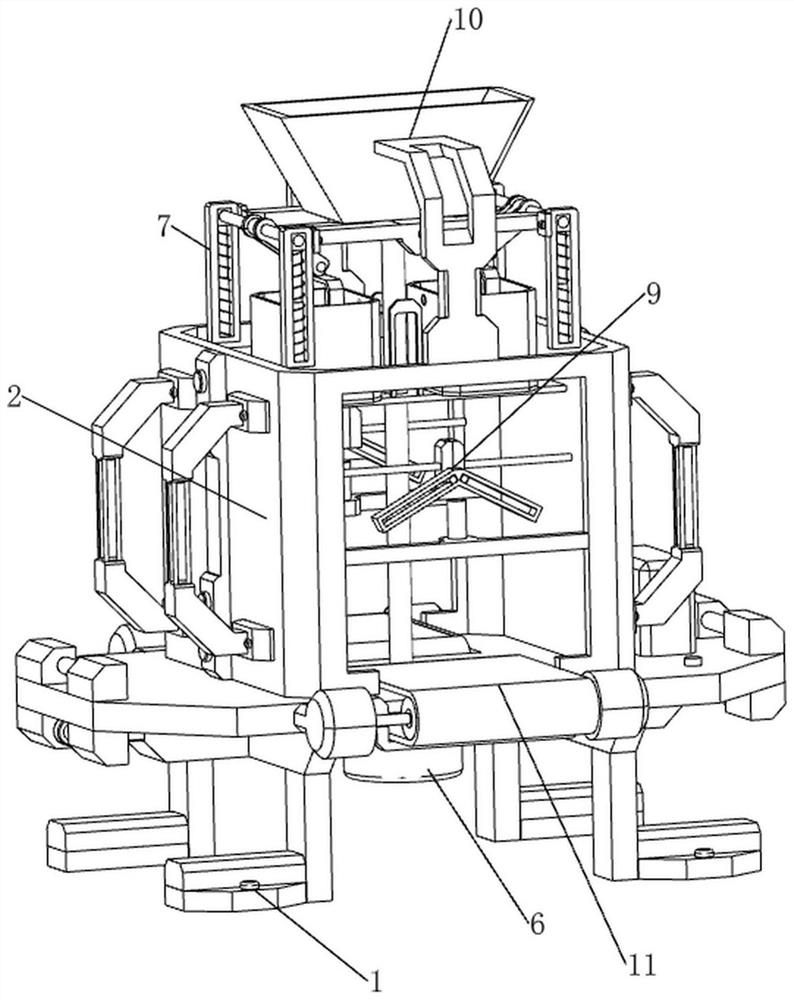

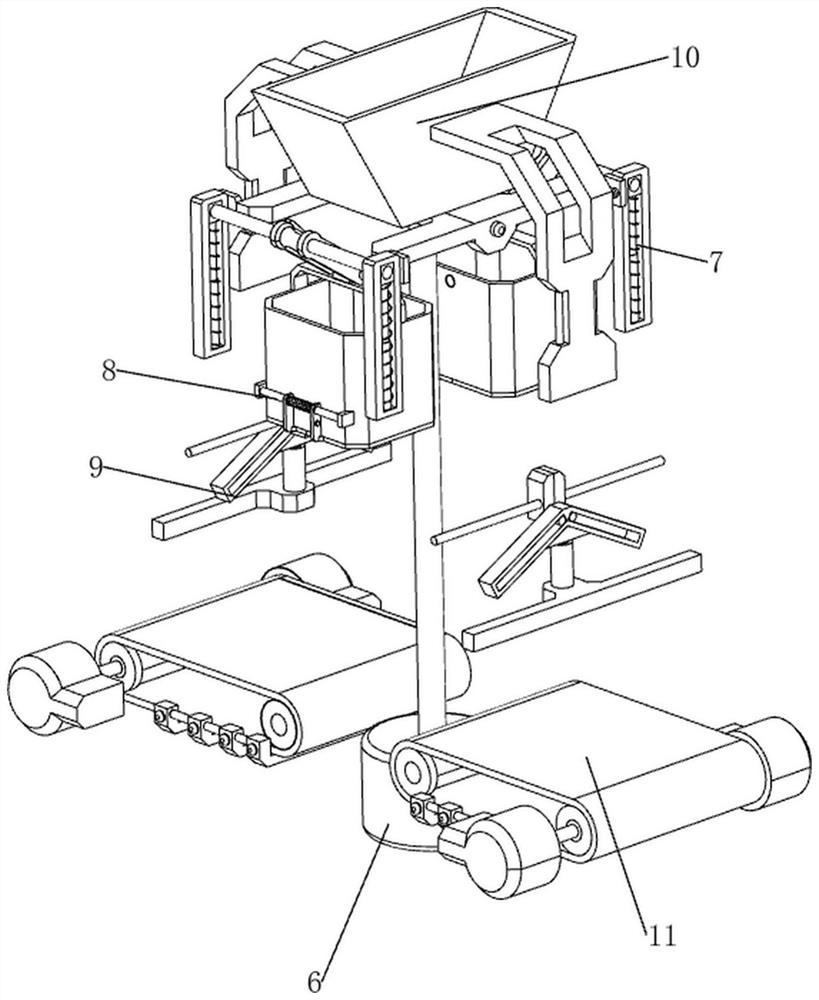

[0034] A quantitative injection device for desiccant processing, such as Figure 1-15 As shown, it includes a bottom frame 1, an outer frame 2, a load bearing plate 4, a pressure sensor 41, a material receiving box 5, a rotating mechanism 6, a quantitative mechanism 7, a discharging mechanism 8 and a pushing mechanism 9, and the bottom frame 1 is welded with an outer Frame 2 and outer frame 2 are provided with a load-bearing plate 4 on the inner upper side, a pressure sensor 41 is provided on the upper right side of the load-bearing plate 4, a rotating mechanism 6 is provided on the bottom frame 1, a quantitative mechanism 7 is provided on the rotary mechanism 6, and a quantitative mechanism 7 Two material receiving boxes 5 are arranged on the top, a material discharging mechanism 8 is arranged on the material receiving box 5, and a pushing mechanism 9 is arranged on the outer frame 2 .

[0035] The rotating mechanism 6 includes a first reduction motor 61, a first rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com