High-position full-automatic stacking machine

A fully automatic, palletizer technology, applied in the stacking of objects, depalletizing, transportation and packaging of objects, etc., can solve the problems of increasing customer procurement costs, waste of customer sites, and inability to achieve the palletizing function alone. The effect of occupying less space for customers, saving manufacturing and processing costs, and requiring low processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

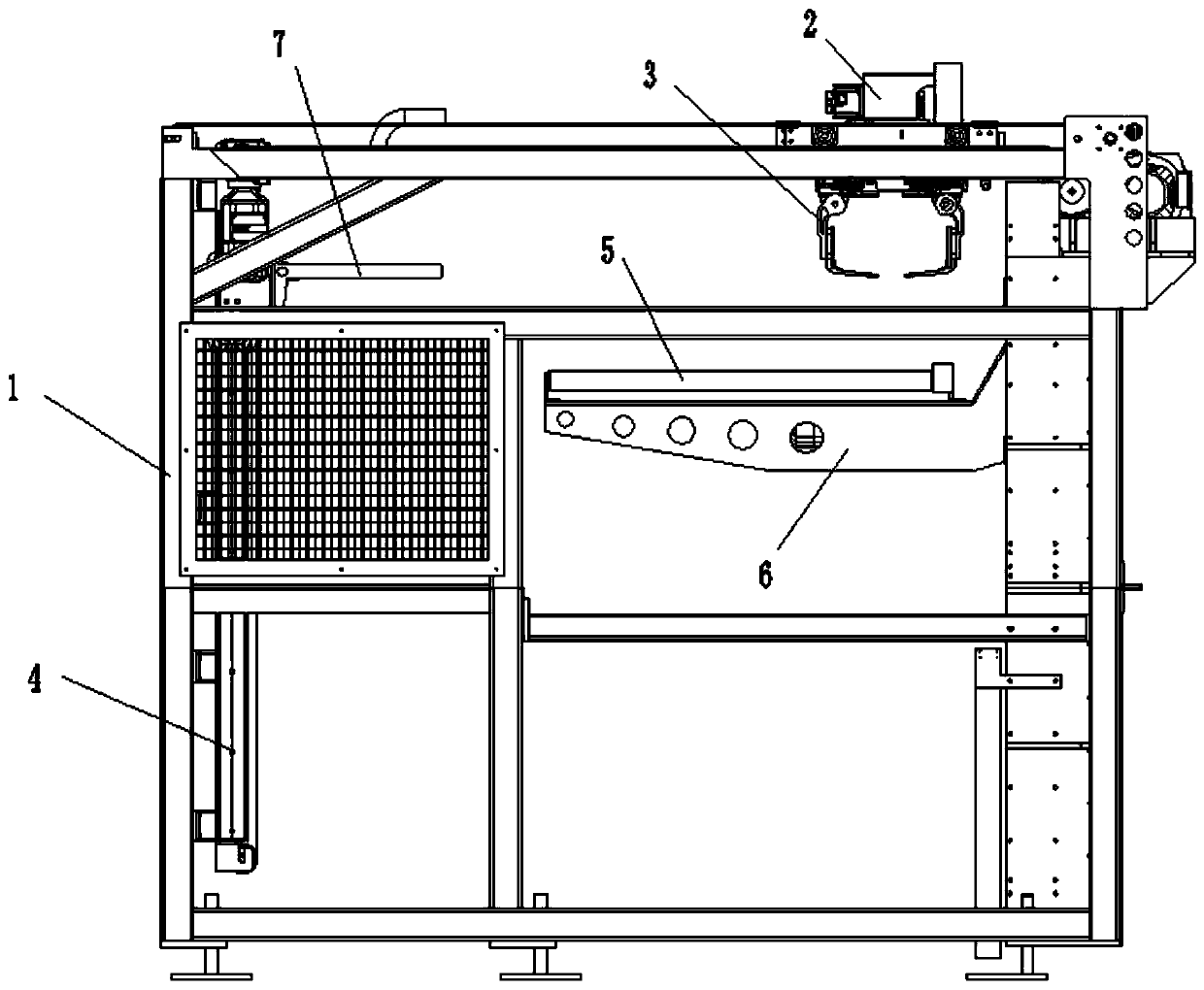

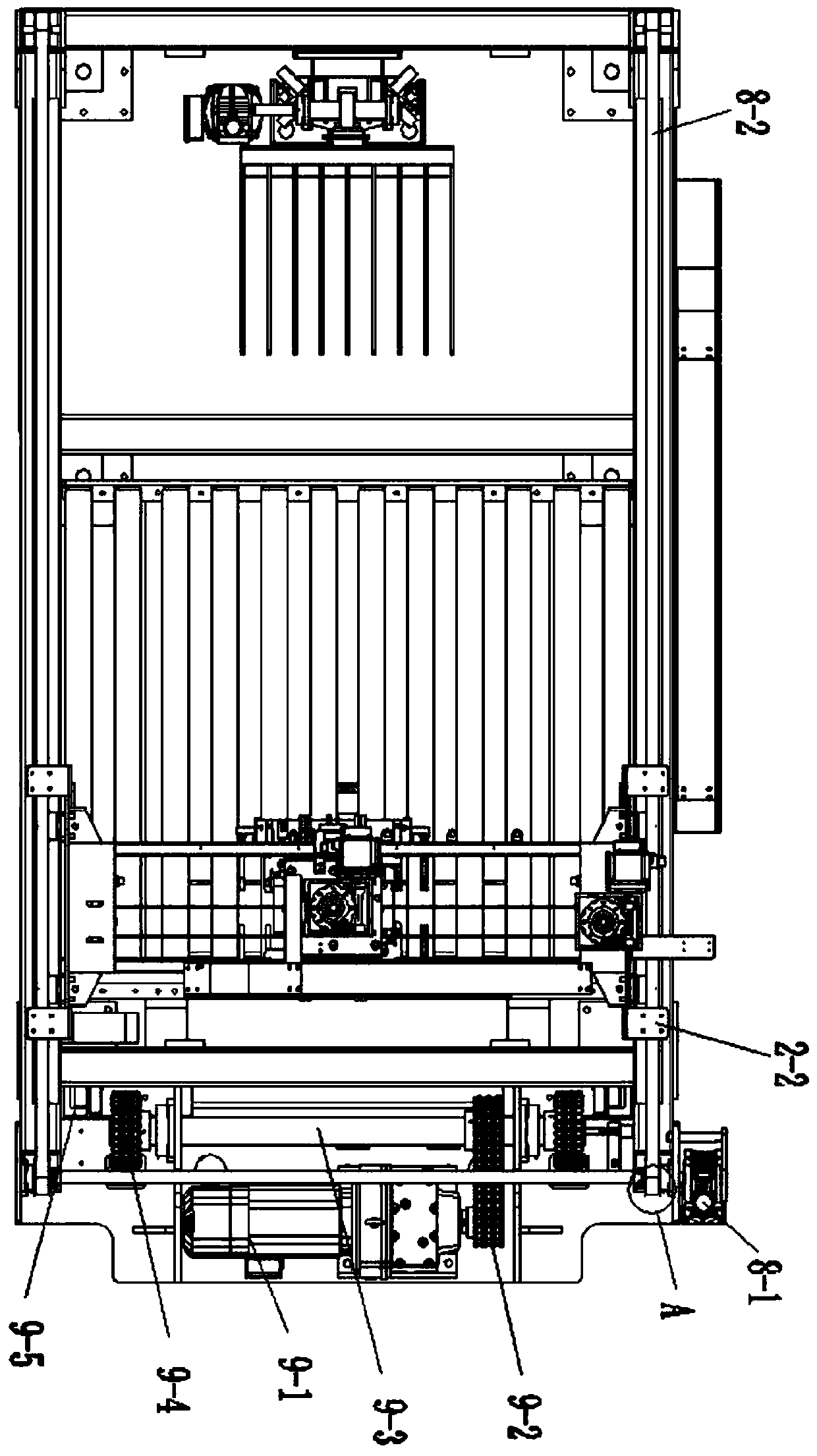

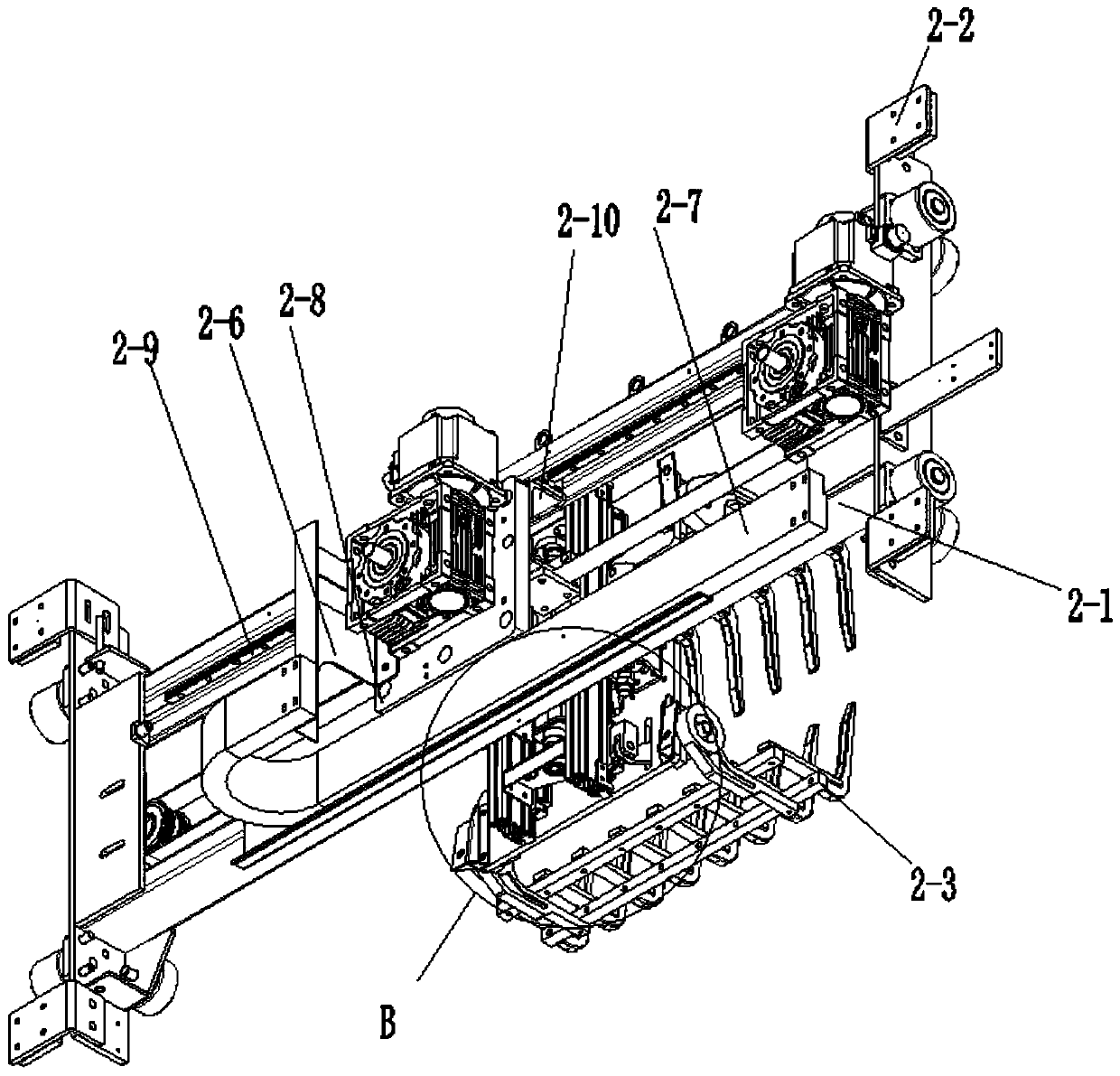

[0027] like figure 1 A high-position fully automatic palletizer shown includes a frame 1, a three-axis transport trolley 2, a gripper 3, a vertical elevator 4, a pallet 5 and a lifting platform 6, and the three-axis transport trolley 2 is installed On the top of the frame, the top of the frame is also provided with a translation mechanism, the three-axis transport trolley is connected with the translation mechanism and moves horizontally through it, and the gripper is arranged at the bottom of the three-axis transport trolley, The pallet is placed on the lifting cargo platform, the lifting cargo platform is connected with the lifting mechanism, the lifting mechanism is arranged on the right inner wall of the frame, and the vertical elevator is arranged on the frame On the left inner wall, the vertical lifter is also connected with a lifter fork 7 . The present invention can realize the function of directly lifting materials vertically from the conveying line to the grabbing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com