Earthwork cloth rolling supporting bracket

A geotextile and rack technology, applied in the direction of winding strips, thin material handling, transportation and packaging, can solve the problems of high labor intensity, large terrain restrictions, inability to drag and drop geotextile rolls, etc. High-efficiency labor intensity, convenient production, installation and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A geotextile rolling bracket of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

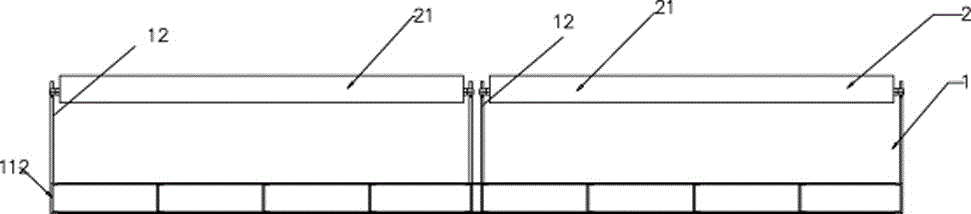

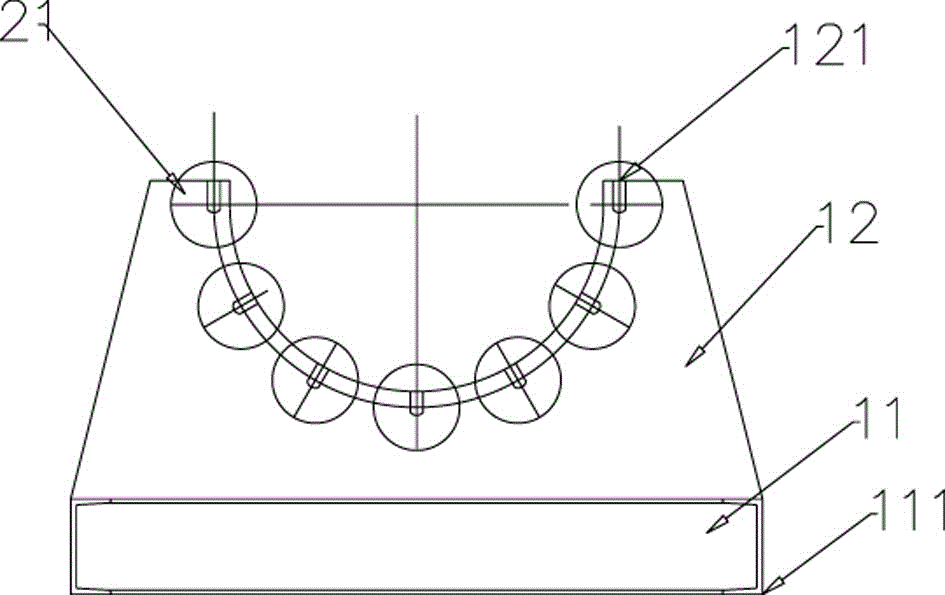

[0015] Such as Figure 1~2 As shown, a geotextile rolling bracket of the present invention includes a frame 1 and a rolling supporting mechanism 2; the frame 1 includes a base 11 and a support plate 12, and the base 11 is divided into two sections on the left and right, and the longitudinal channel steel 111 and transverse channel steel 112 are welded together. The support plate 12 is provided with two sets of four pieces in total, one set at each left and right end of each group, and each support plate is a trapezoidal steel plate with a groove on the upper end. Seven evenly distributed fixing grooves 121 are arranged on the edge of the groove, and the lower end of the support plate 12 is welded and fixed to the base 11; Seven idler rollers 21 are evenly arranged on the inner side along the upper groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com