Tower crane attachment device

A technology of attachment device and tower crane, applied in cranes and other directions, can solve the problems of lack of tower crane stability and water leakage in pre-embedded positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

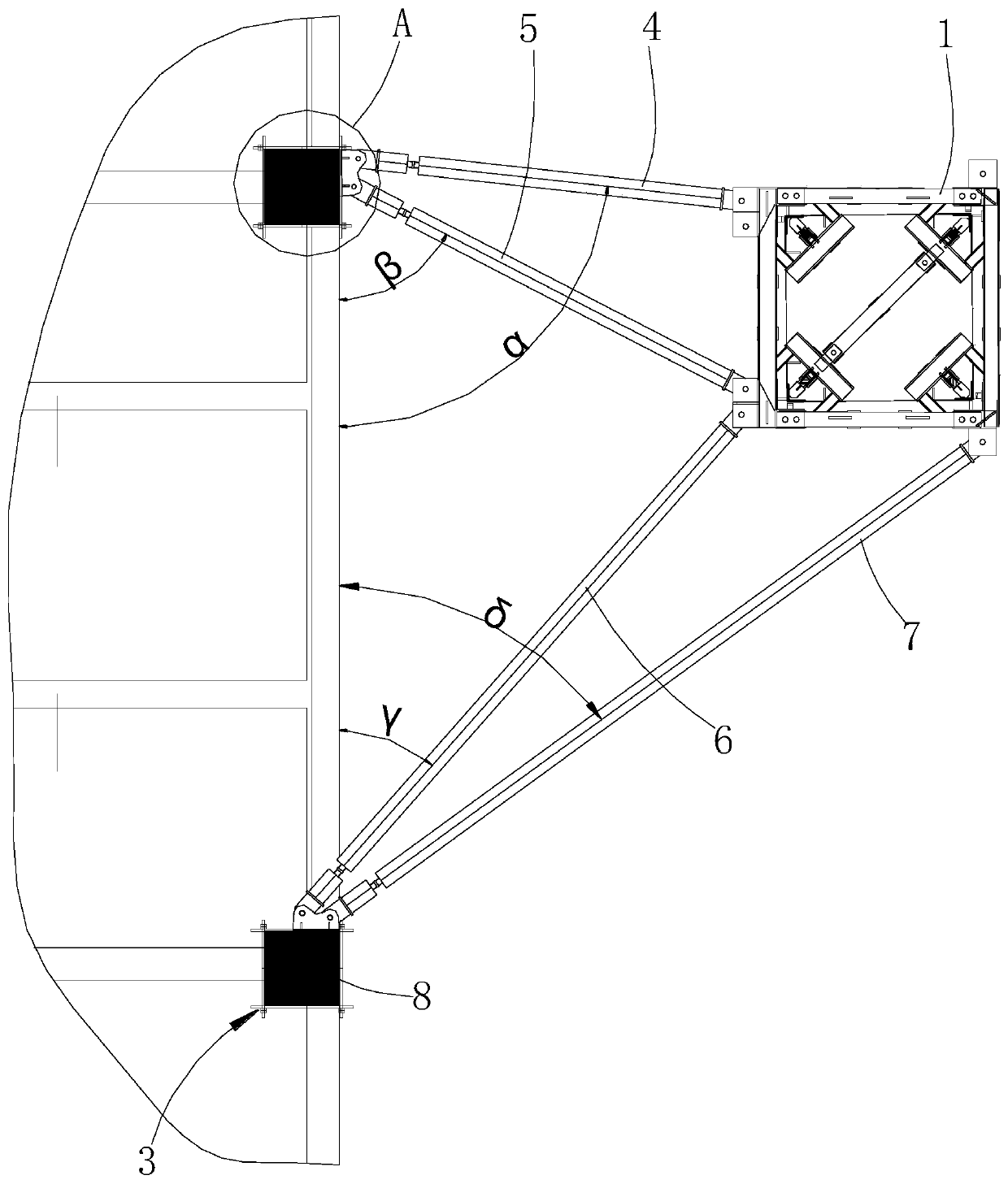

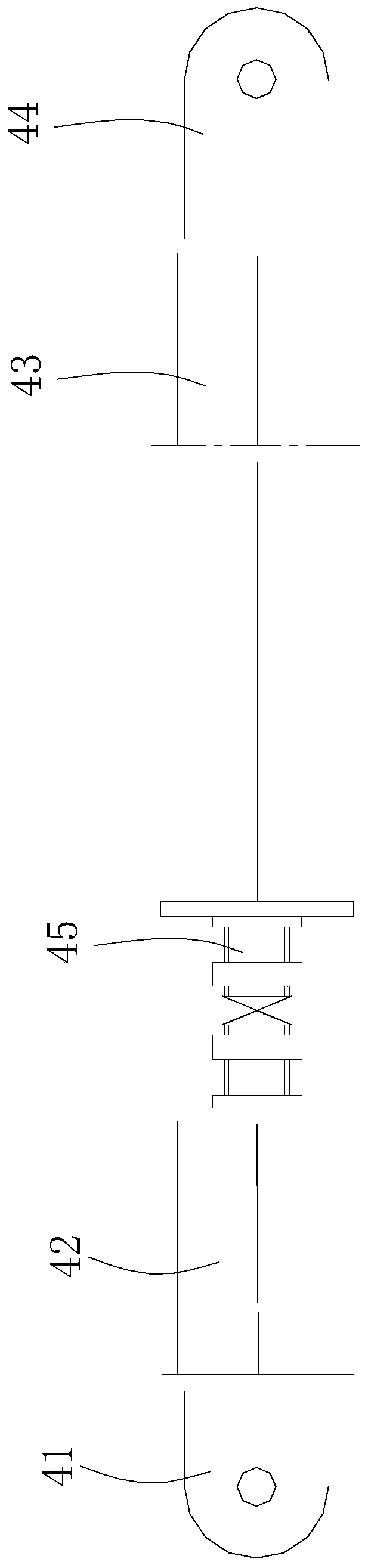

[0016] Such as Figures 1 to 3 shown

[0017] The attachment device includes a standard joint attachment frame 1, four connecting rods and two groups of hoop assemblies.

[0018] The standard section attachment frame 1 adopts a commercially available standard section attachment frame 1, and the standard section attachment frame 1 is fixed between the two standard section arms of the tower crane.

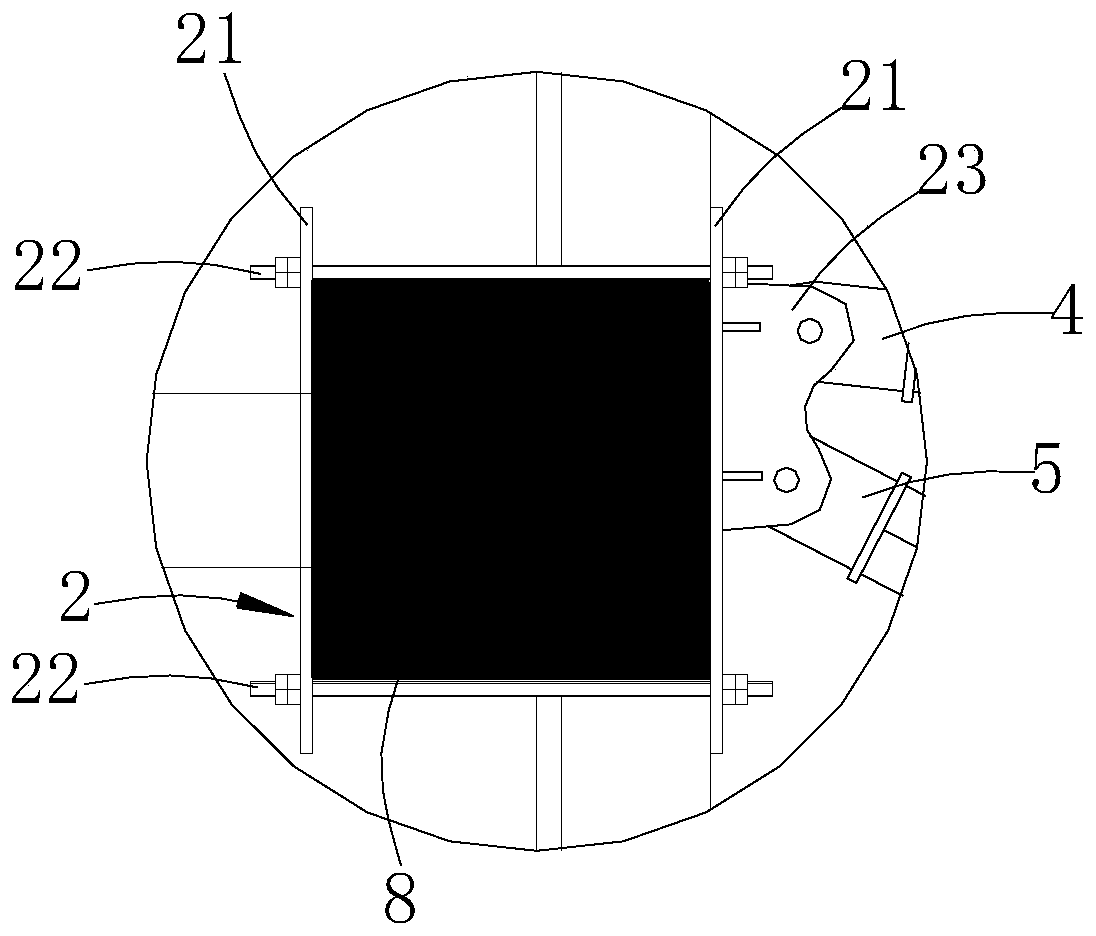

[0019] The two groups of hoop assemblies are the first hoop assembly 2 and the second hoop assembly 3 respectively. The first hoop assembly 2 and the second hoop assembly 3 have the same structure. The first hoop assembly 2 is used as an example to introduce the hoop assembly. The structure of the hoop assembly, the first hoop assembly 2 includes two holding plates 21 and six fixing bolts 22, the two holding plates 21 are respectively close to the two sides of the concrete column 8 of the main building, and the two holding plates 21 are passed through six Two fixing bolts 22 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com