Electromagnetic drying device for yarn sizing machine

A technology of drying device and sizing machine, which is applied in textile and paper making, liquid/gas/vapor removal, textile material processing, etc., can solve problems such as easy scalding of silk threads, and achieve the effect of avoiding excessive temperature and reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

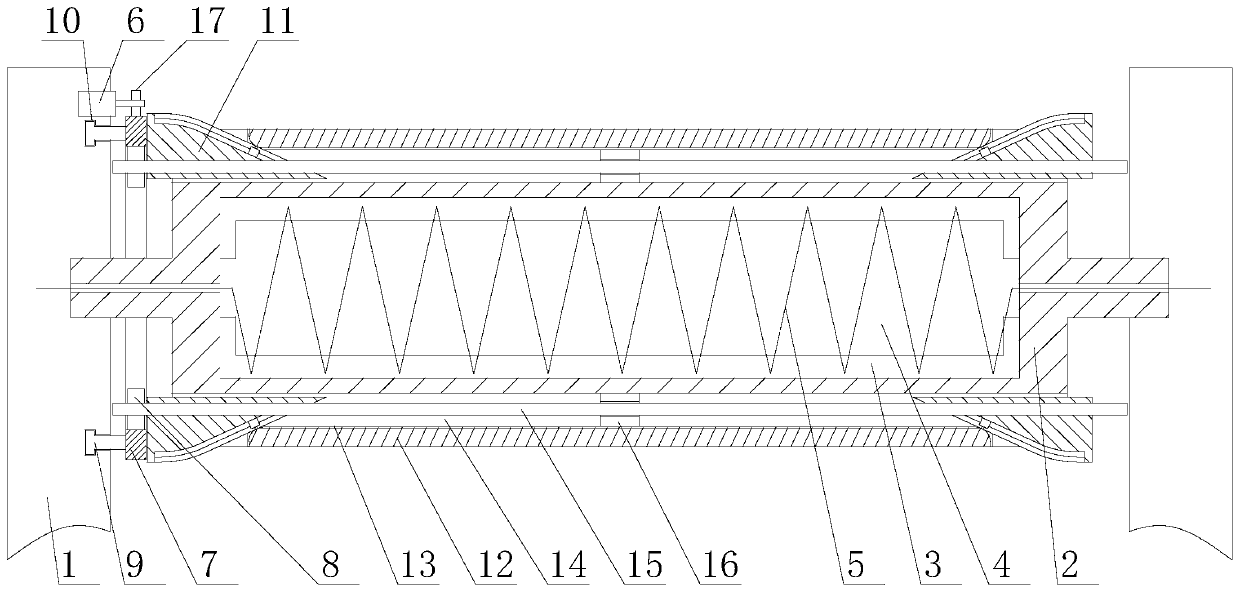

[0033] Based on the above-mentioned purpose, the first aspect of the present invention proposes an embodiment of an electromagnetic drying device for a pulping machine, such as figure 1 shown, including

[0034] Two supporting legs 1, which are respectively fixed on both sides of the sizing machine;

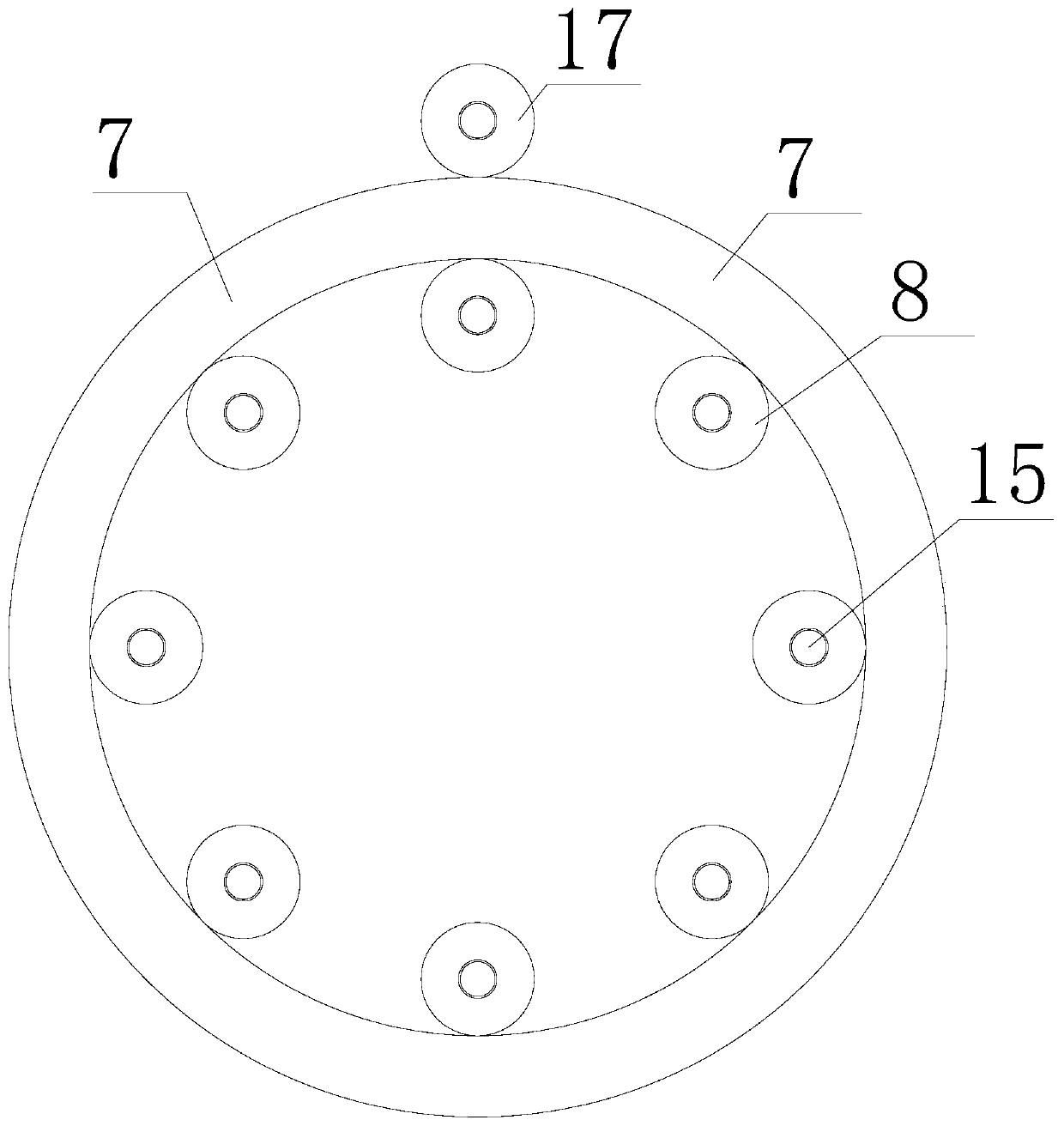

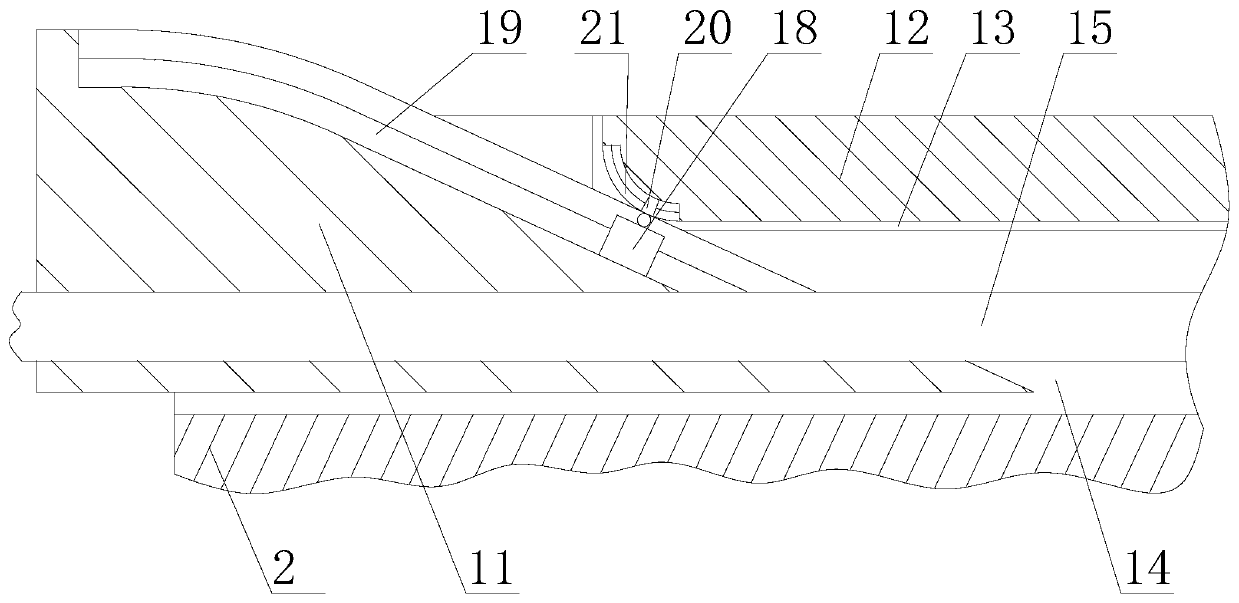

[0035] There is a drying roller 2 inside the inner cavity 3 and an iron rod 4 located in the inner cavity 2. The drying roller 2 is located between the legs 1, and the two ends of the drying roller 2 are rotatably connected with the corresponding legs 1. , the two ends of the iron rod 4 are fixed on the end face of the inner cavity 2;

[0036] The induction coil 5 sleeved on the iron rod 4 is connected to the power supply ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap