A method for checking accuracy of residual stress by xrd method and calculating method for shear stress

A technology of residual stress and calculation method, which is applied in the direction of measuring force, measuring device, force/torque/work measuring instrument, etc. It can solve the single detection result of XRD method, the inability to express the state of residual stress in the plane, and the inability to provide the distribution of shear stress, etc. problem, achieve the effect of ensuring normal operation and widening the detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

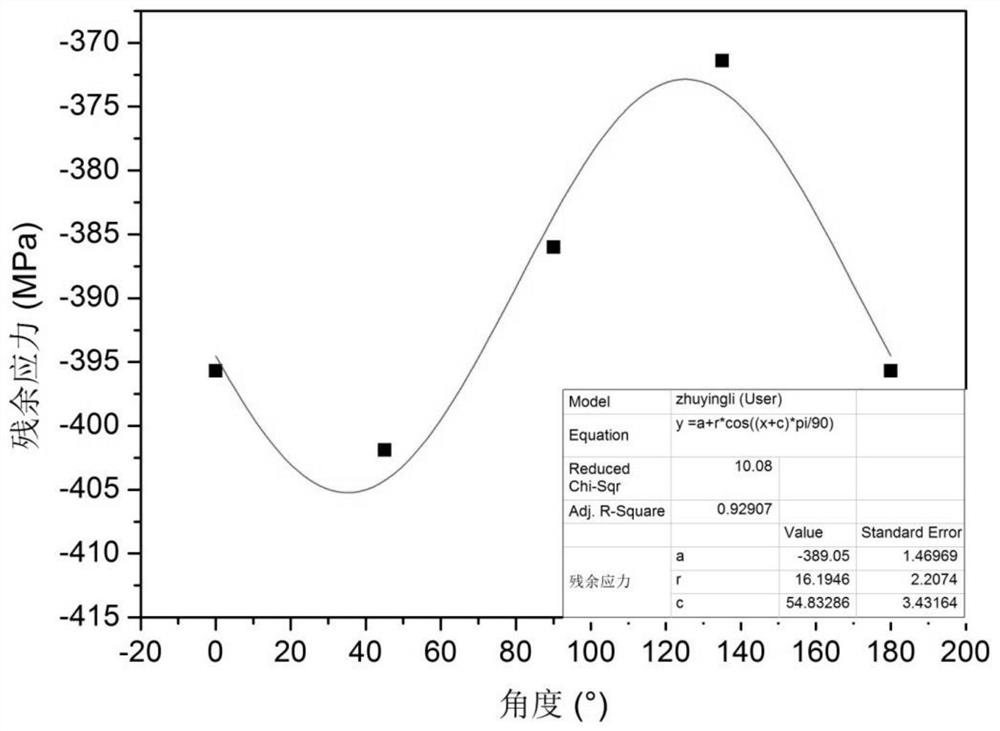

[0041] Embodiment 1 takes rolling direction as 0 ° direction, and angle measurement is positive with counterclockwise, carries out 45 °, 90 °, 135 °, 180 ° (0 °) altogether according to implementation steps 1~5 to hot-rolled steel strip sample 4 directions for measurement, data fitting and error analysis, as shown in Table 1, Table 4 and attached figure 1 shown.

Embodiment 2

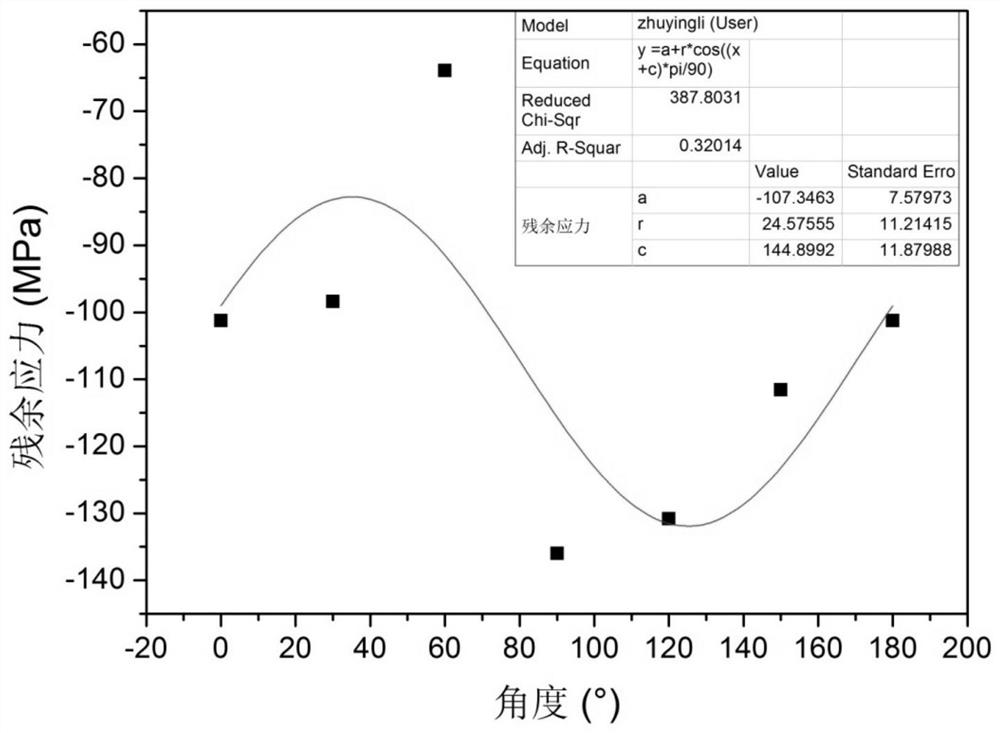

[0042] Embodiment 2 takes the rolling direction as the 0° direction, and the angle measurement is positive in the counterclockwise direction, and the hot-rolled strip steel sample is subjected to 30°, 60°, 90°, 120°, 150°, 180° according to the implementation steps 1 to 5. ° (0°) in total 6 directions for measurement, data fitting and error analysis, as shown in Table 2, Table 4 and attached figure 2 shown.

Embodiment 3

[0043] In Example 3, the rolling direction is defined as the 0° direction, and the angle measurement is taken as positive in the counterclockwise direction, and the hot-rolled strip steel samples are subjected to 22.5° and 45° according to the implementation steps 1-5. 67.5°, 90°, 112.5°, 135°, 157.5°, 180° (0°) in 8 directions for measurement, data fitting and error analysis, as shown in Table 3, Table 4 and attached image 3 shown.

[0044] Table 1 Example 1 Residual stress results measured value, fitting value and deviation analysis under different angles

[0045] Angle / ° 45 90 135 180(0) Measured value / MPa -401.9 -386.0 -371.4 -395.7 Fitting value / MPa -404.3 -383.6 -373.8 -394.5 Deviation / MPa 2.4 2.4 2.4 1.2 Deviation percentage / % 0.59 0.63 0.64 0.30

[0046] Table 2 Example 2 Residual stress results measured value, fitting value and deviation analysis under different angles

[0047] angle 30 60 90 120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com