A high-efficiency spraying device for rotating material-guided building decorative panels

A technology for architectural decoration and spraying equipment, which is applied in the direction of spraying equipment and spray booths, etc., which can solve the problems of uniform position adjustment of spray paint, insufficient independent operation ability, influence on plate processing efficiency, and increase the cost of spray paint, etc., to achieve good material quality The effect of spraying connection ability, improving independent operation ability and improving spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

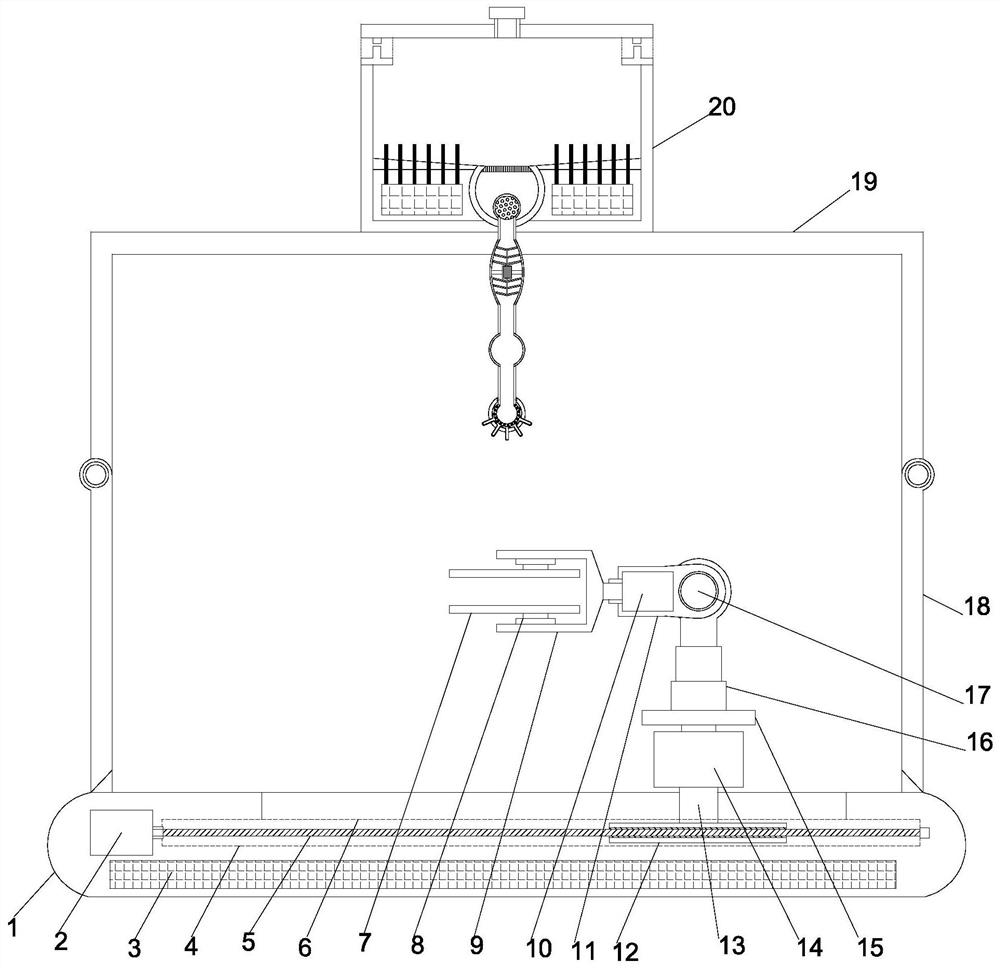

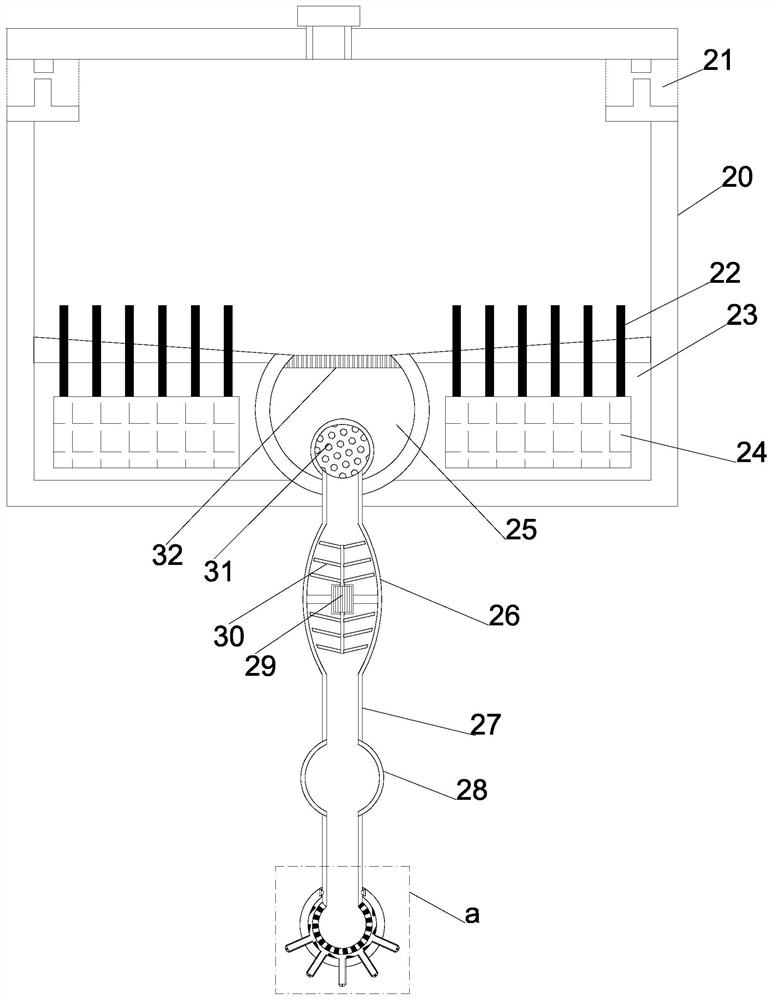

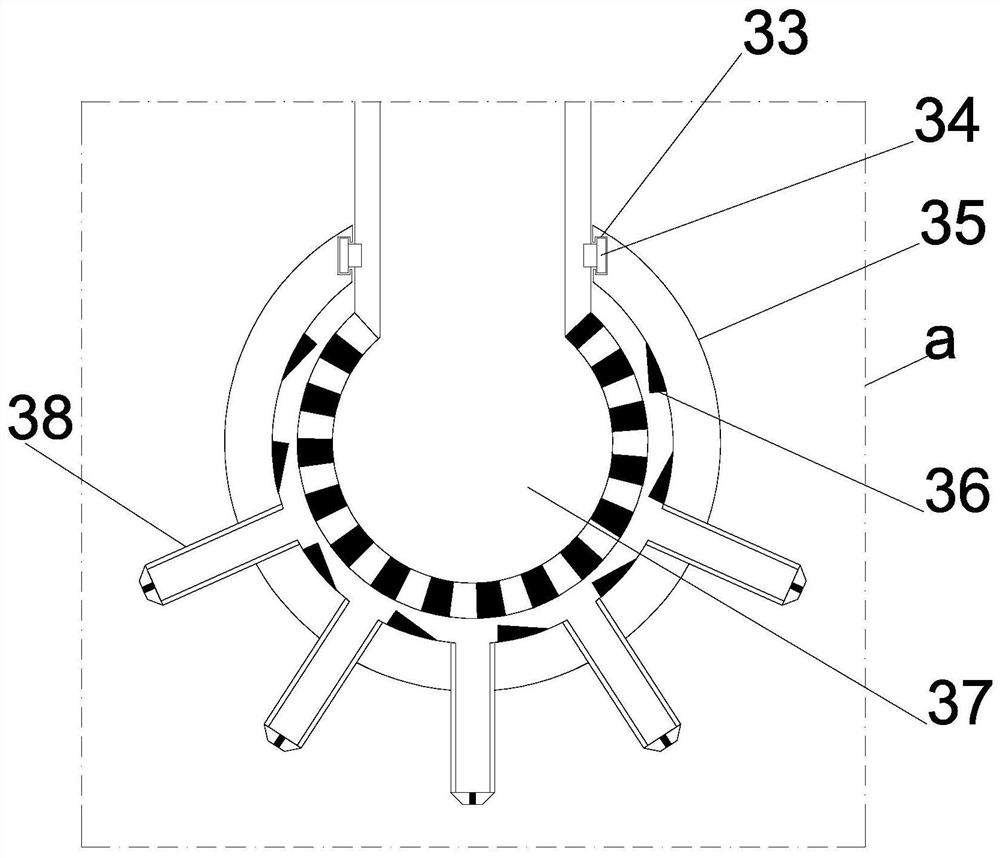

[0022] see Figure 1~4 , in the embodiment of the present invention, a kind of high-efficiency spraying device of rotating guide type building decorative board, comprises the support installation plate 1 that is arranged horizontally, the upper end of support installation plate 1 is vertically provided with support installation tube 19, and the bottom of support installation tube 19 Both sides of the half section are provided with rotary gates 18, and the upper middle position of the supporting installation cylinder 19 is vertically provided with a spraying installation cylinder 20, and the lower half of the spraying installation cylinder 20 is horizontally provided with a cone deflector 23, and the cone surface The middle position of the deflector 23 is concavely provided with a confluence installation cylinder 25 downward, and the upper end of the confluence installation cylinder 25 is horizontally provided with a porous slow-flow plate 32, and the conical surface deflector 2...

Embodiment 2

[0025]On the basis of Embodiment 1, the battery pack 3 and the independent battery 24 are used to supply power, so that the device can run independently for a period of time, which can solve the problem of uneven spraying of the plate when the power is suddenly cut off, and move the guide holes by moving the guide plate 13 6 to ensure that the device can move through stably, and the driving shaft 17 can quickly switch the clamping direction of the device, improving the practicability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com