Washing device for heptafluoropropane storage tank and method thereof

A technology for heptafluoropropane and cleaning device, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., and can solve the problems of poor use effect, residual water stains, slow drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

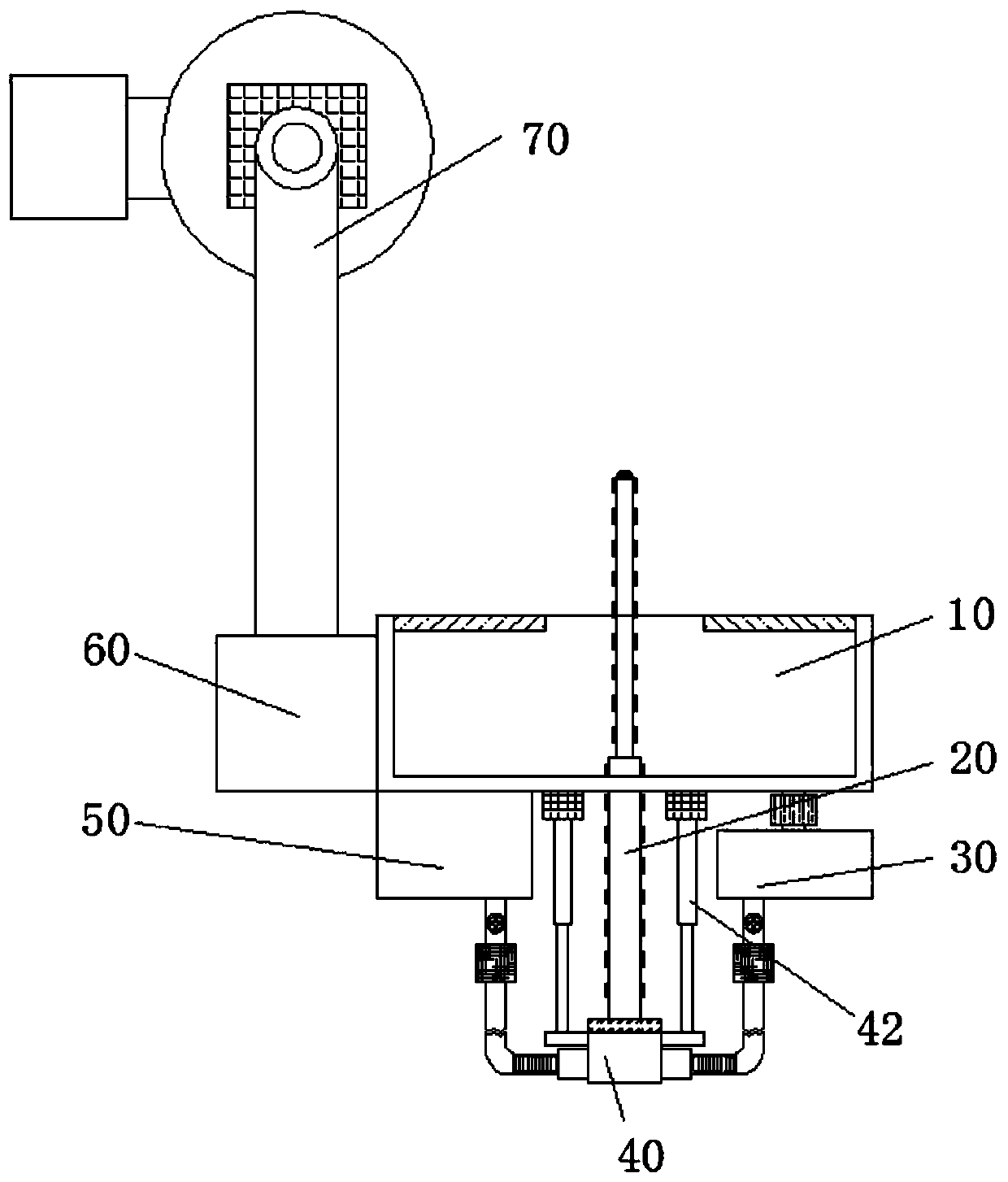

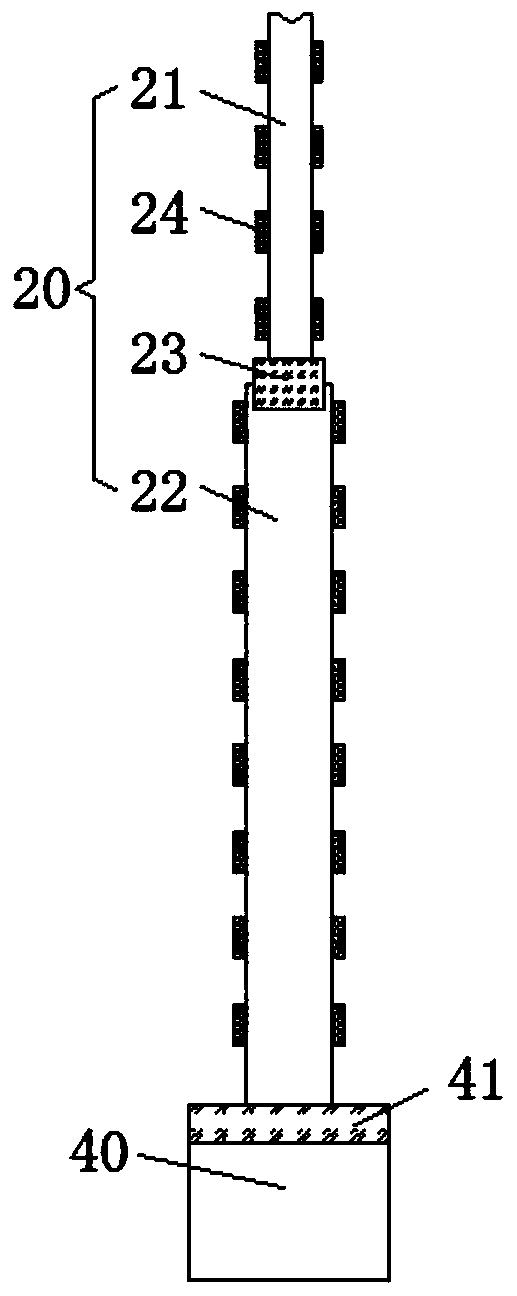

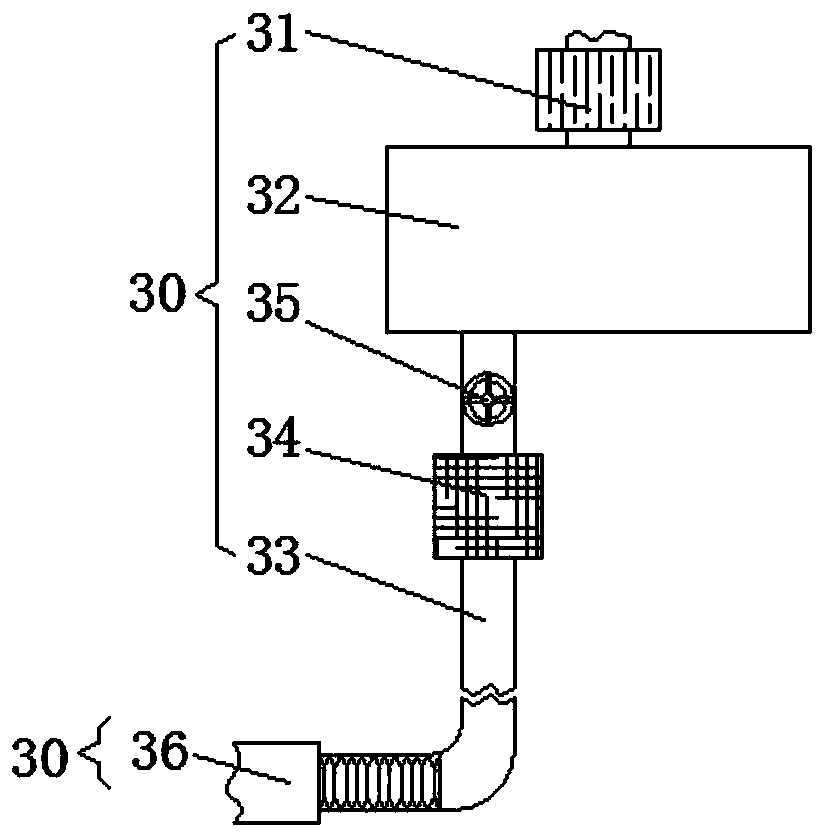

[0030] Such as figure 1 As shown, the heptafluoropropane storage tank cleaning device described in this embodiment includes a cleaning bin 10, a water spray mechanism 20, a water supply mechanism 30, a temporary storage bin 40, an air supply mechanism 50, a fixing seat 60 and a turning mechanism 70, and the cleaning bin 10 The center is equipped with a water spray mechanism 20, the bottom of the water spray mechanism 20 is provided with a temporary storage bin 40, the bottom bolt of the cleaning bin 10 is fixed with a hydraulic rod 42 that drives the temporary storage bin 40 to move, and one side of the bottom of the cleaning bin 10 is provided with There is a water supply mechanism 30 for supplying water to the water spray mechanism 20, and the other side of the bottom of the cleaning chamber 10 is provided with an air supply mechanism 50 for supplying air to the water spray mechanism 20. One side of the cleaning chamber 10 is fixed with a fixed seat 60, and the fixed seat 60 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap