A kind of food waste hydrolysis processing method

A technology of kitchen waste and treatment method, which is applied in the fields of water/sewage multi-stage treatment, flotation water/sewage treatment, adsorbed water/sewage treatment, etc., and can solve the problems of complex separation and treatment steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

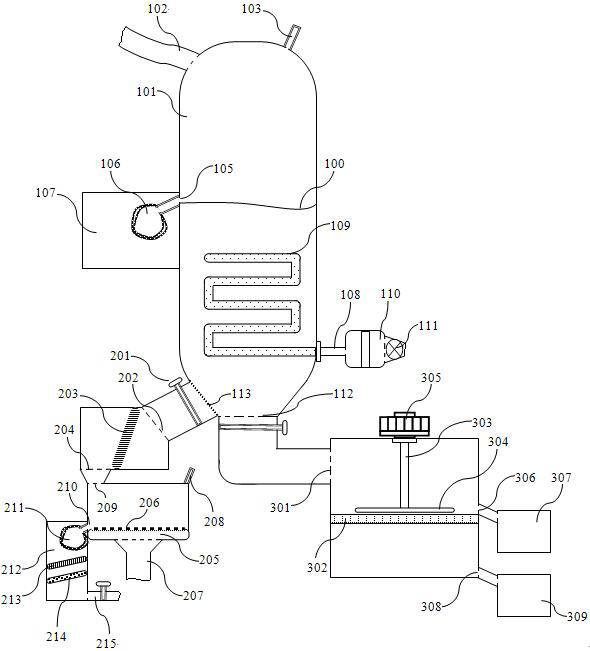

Image

Examples

Embodiment 2

[0039] A method for hydrolysis treatment of kitchen waste, the treatment method is carried out using the kitchen waste hydrolysis treatment device described in Example 1, specifically comprising the following steps:

[0040] 1) Put the kitchen waste into the hydrolysis high-pressure tank through the feed port of the hydrolysis tank, close the exhaust pipe of the hydrolysis tank, close the oil discharge port, close the sewage inlet valve, close the discharge port of the hydrolysis tank, and close the hot dry air inlet. When the material in the hydrolysis high-pressure tank reaches 10% of the total volume, open the hot dry air inlet, adjust the temperature of the hot dry air to 115°C, and open the exhaust pipe of the hydrolysis tank at the same time.

[0041] 2) When the material in the high-pressure hydrolysis tank reaches 55% of the total volume, close the exhaust pipe of the hydrolysis tank, increase the temperature of the hot dry air to 125°C, and after the pressure in the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com