High-efficiency double-row whole-rod type sugarcane combine harvester

The technology of a double-row whole-rod type and combine harvester is applied in the field of high-efficiency double-row whole-rod type sugarcane combine harvesters, which can solve the problems of high sugar cane loss rate and low efficiency of sugarcane harvesters, and reduce labor intensity. , reduce labor input, improve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

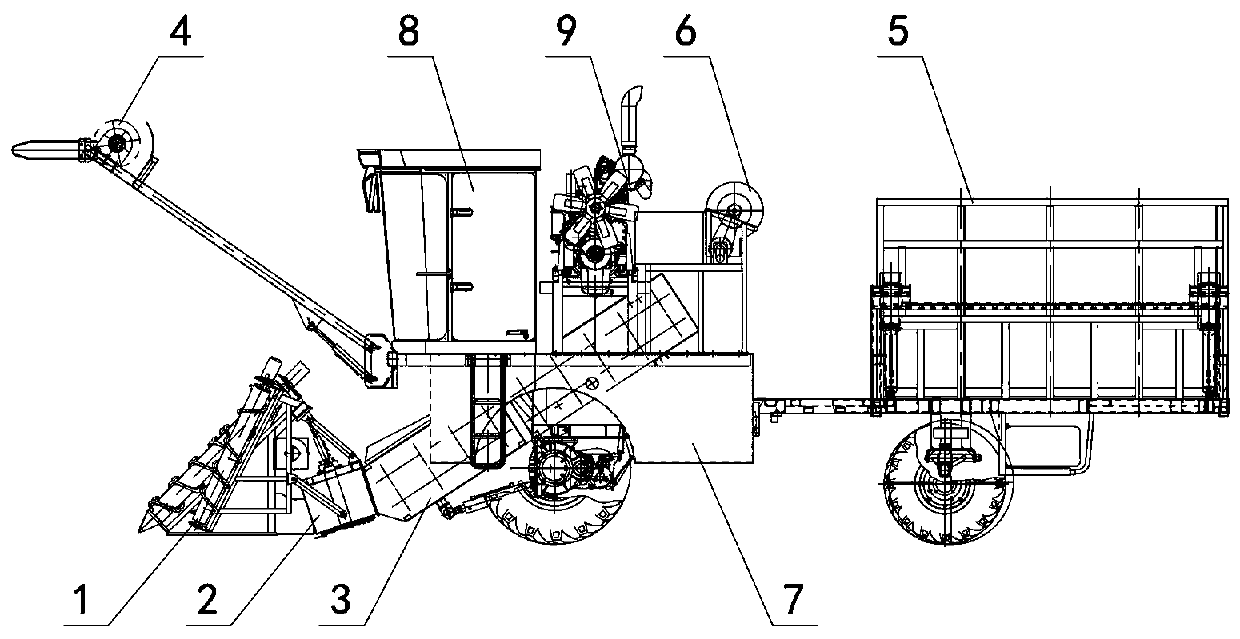

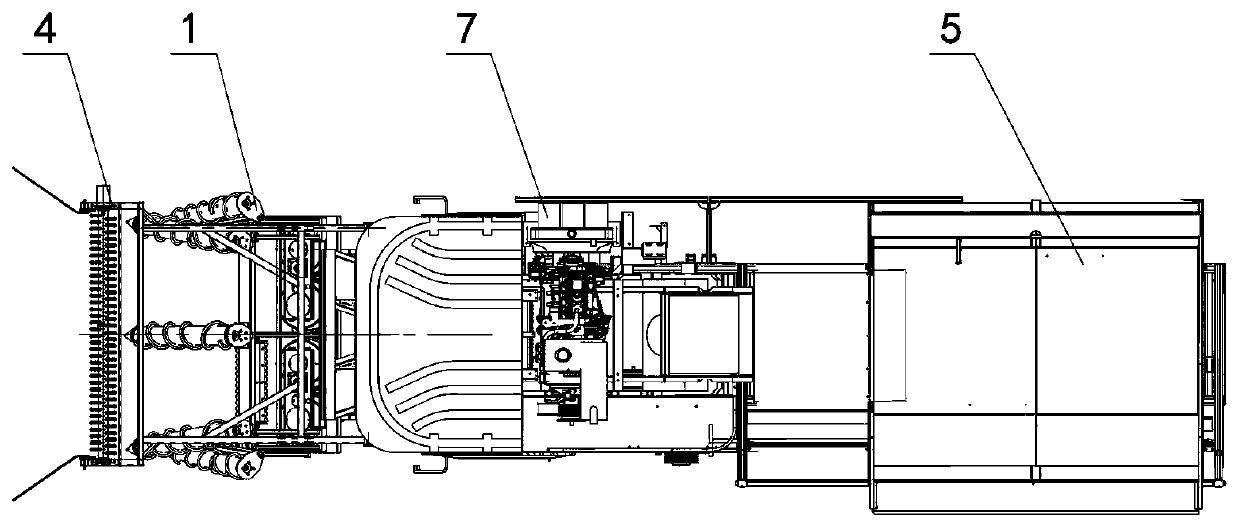

[0044] The high-efficiency double-row full-rod sugarcane combine harvester includes a chassis 7, which is equipped with a front axle assembly, a rear axle assembly, an engine 9, a gearbox, and a cab 8, and a tip-cutting mechanism is overhanging and hinged above the front end of the chassis 7. 4. The central part of the chassis 7 is obliquely equipped with a conveying leaf stripping mechanism 3, the front end of the conveying leaf stripping mechanism 3 is fixed with a header mechanism 2, the front end of the header mechanism 2 is fixed with a sugarcane support mechanism 1, and the rear end of the conveying leaf stripping mechanism 3 is fixed with a The blower 6 is facing downward, and the rear side of the blower 6 is provided with a sugarcane bin 5;

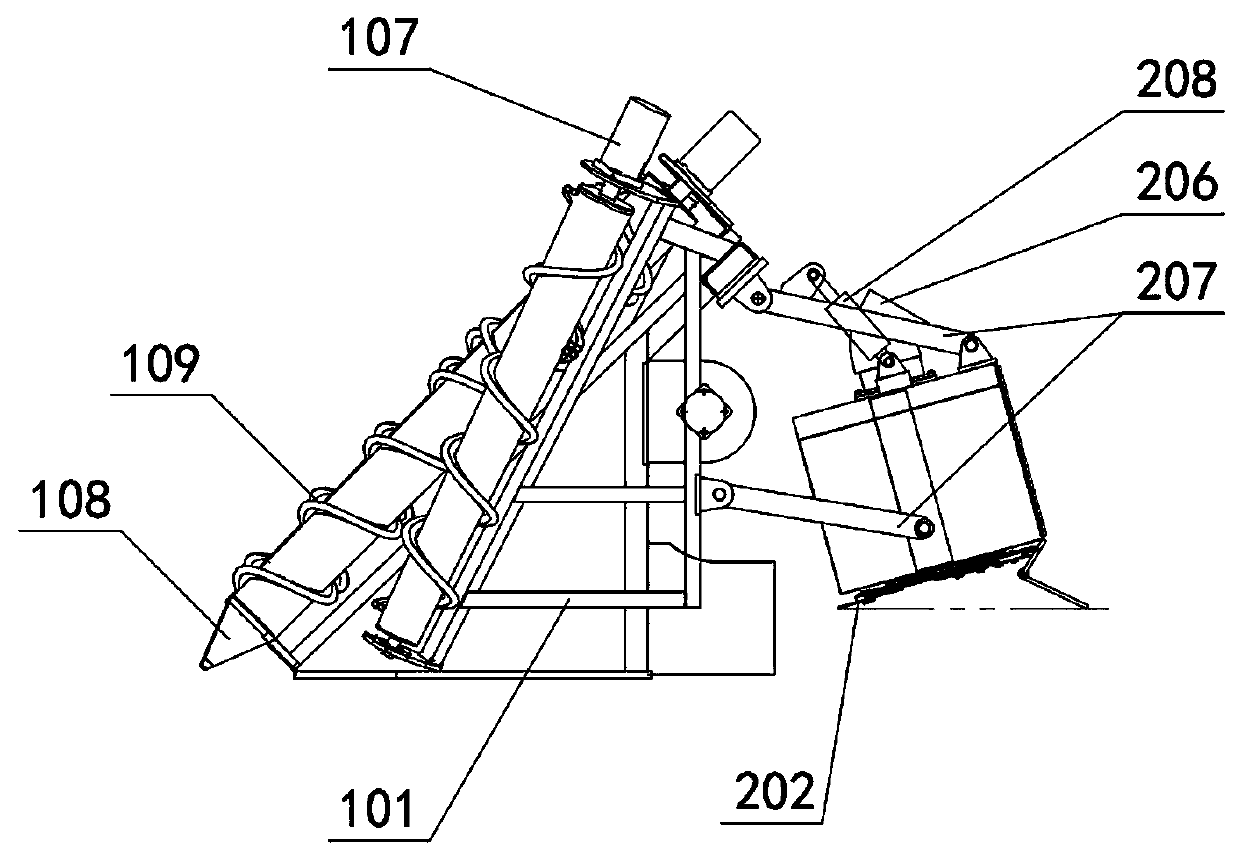

[0045] The cane-supporting mechanism 1 includes a cane-supporting support 101, on which a left outer cane-supporting cylinder 102, a left inner cane-supporting cylinder 103, a middle cane-supporting cylinder 104, a right inner cane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com