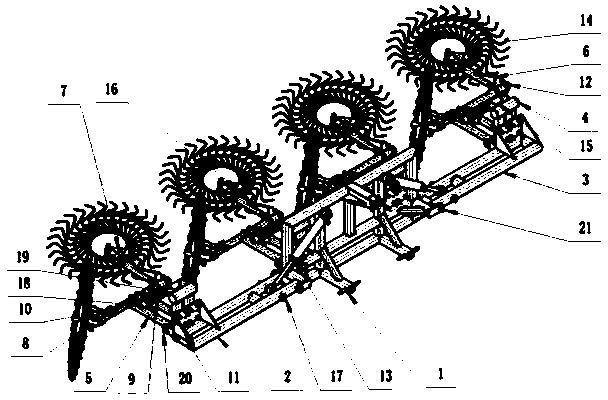

Rear-mounted four-row adjustable corn straw strip collecting machine

A corn stalk and sliver collecting machine technology, which is applied to harvesters, crop processors, agricultural machinery and implements, etc., can solve the problems of wasting stalk resources, backward farming modes, polluting the environment, etc., and achieves convenient installation and use, and improves the emergence rate. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

[0010] Such as figure 1 As shown, the present invention comprises a main frame 1, and the main frame 1 is installed on the rear three-point suspension of the tractor through suspension points. The left expansion frame 3 and the right expansion frame 2 are respectively connected to both sides of the main frame 1 through the hinge shaft (expansion frame) 21, and then the main frame 1 is connected with the left expansion frame 3 and the right expansion frame 2 through the lifting cylinder 13, and the lifting The cylinder body of the oil cylinder 13 is installed on the main frame 1, and the hydraulic rod is connected to the left unfolding frame 3 and the right unfolding frame 2 through the hinge shaft (oil cylinder) 17 to form a foldable working mechanism, and the oil circuit of the lifting oil cylinder 13 is connected to the The hydraulic system of the tractor puts the left unfolding frame 3 and the right expanding frame 2 in a horizontal wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com