Front double-row three-column straw cleaning machine

A technology for cleaning machines and straws, which is applied in the fields of soil preparation machinery, agricultural machinery and implements, applications, etc., can solve the problems of wasting straw resources, backward land protection, soil erosion, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

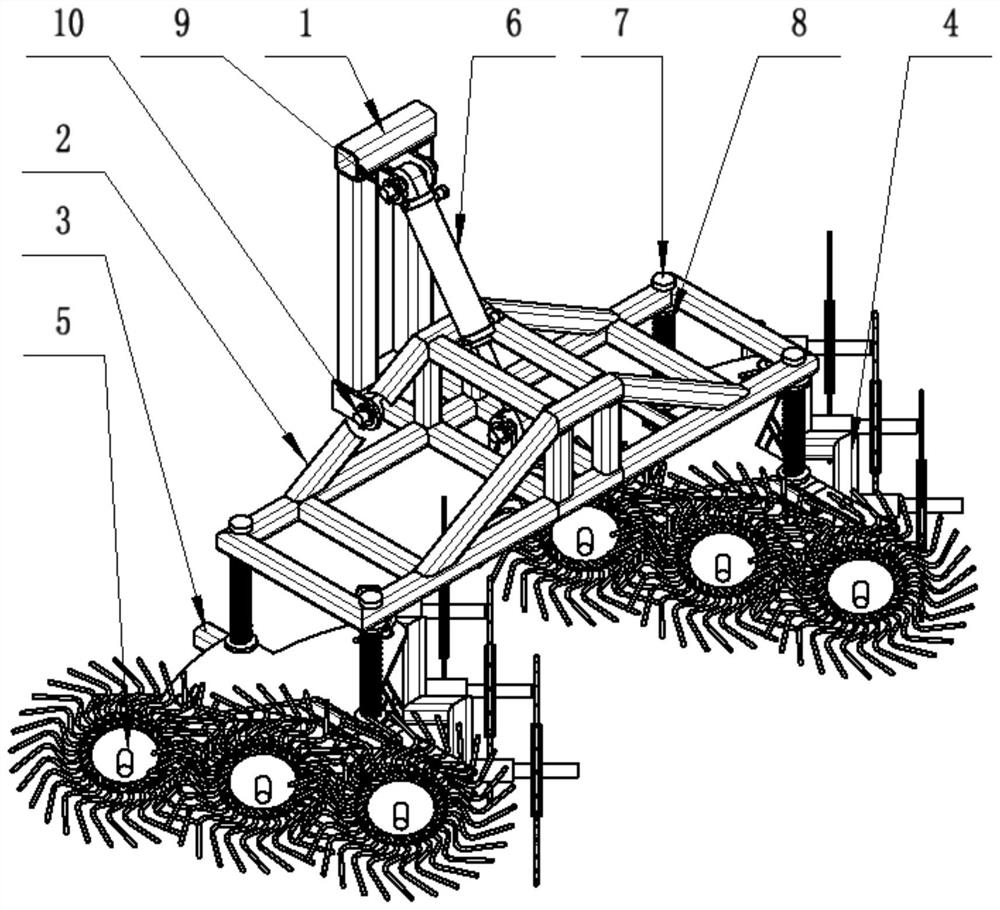

[0010] Such as figure 1 As shown, the present invention includes a main frame 1, the main frame 1 of the straw cleaning machine is connected with the front counterweight of the tractor with a U-shaped clip through a self-made connecting piece (because the tractor manufacturer and model are different), and the front counterweight of the tractor is connected, and adjusted Machine ground clearance. The connecting frame 2 and the main frame 1 are connected together with the long connecting pin 10, the hydraulic rod end of the hydraulic cylinder 6 is connected with the connecting frame 2, and the fixed end of the hydraulic cylinder 6 is connected with the main frame 1 of the straw cleaning machine through the short connecting pin 9. Together, a triangular mechanism that can change the working height is formed. The oil inlet and outlet of the hydraulic cylinder 6 are connected with the hydraulic system of the tractor through the hydraulic oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com