Single-row seedling strip tillage and preparation combined machine in straw row-returning mode

A combined working machine and single-row seedling technology, applied in agricultural machinery and implements, agriculture, and agricultural machinery, etc., can solve the problems of soil compaction, insufficient soil quality, slow ground temperature rise, etc. ground temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

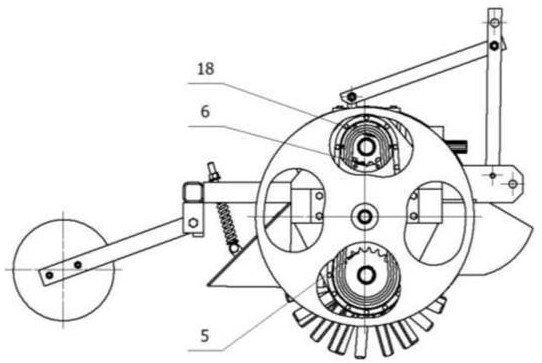

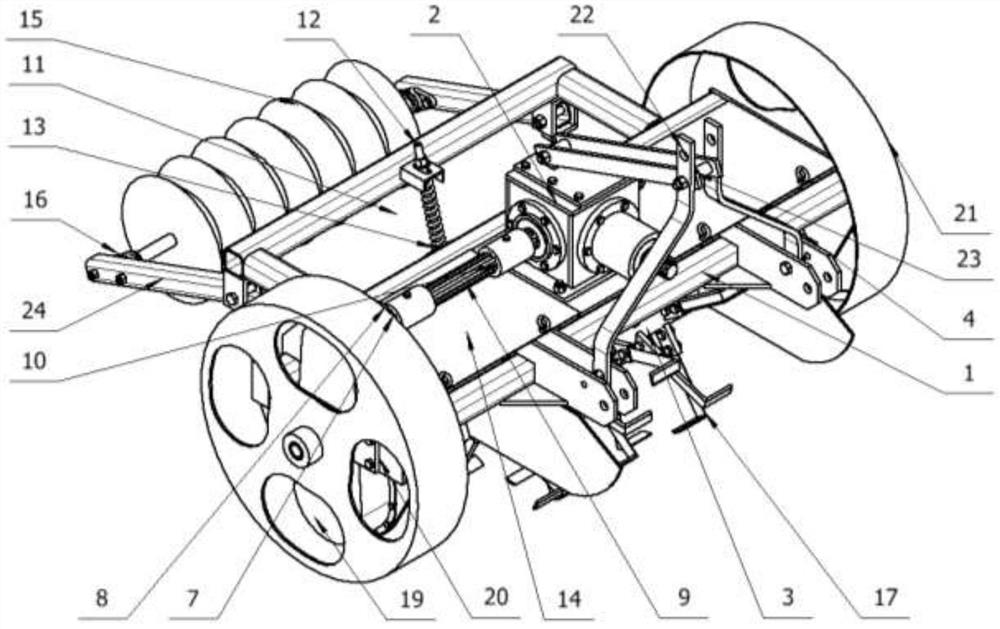

[0010] Such as figure 1 , figure 2 As shown, the present invention comprises a frame 1, puts the gearbox 2 of the single-row seedling belt plowing combined operation machine on the designated position of the frame 1, makes the input shaft of the gearbox 2 face the tractor, and fixes it with bolts, and installs it on the suspension respectively. Rod 23 and suspension lower rod 22, the upper suspension rod 23 is installed on the top of the gearbox 2, the lower suspension rod 22 is installed on the frame 1, the upper suspension rod 23 and the lower suspension rod 22 are connected together to form a complete suspension mechanism , install the bearing on the sprocket drive shaft 7, and insert the bearing into the upper bearing seat 8, then install the upper bearing seat 8 on the side plate of the frame 1 and fix it so that the spline on the sprocket drive shaft 7 Facing the gearbox 2, the left and right ends of the rotary tillage shaft 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com