Nose-bridge-free protective mask and high-speed rotary die cutting production process and production equipment thereof

A technology of high-speed rotation and masks, which is applied to protective clothing, textiles, papermaking, and other household appliances. It can solve the problems of complex production equipment, high cost, and impact on production efficiency, so as to simplify equipment, reduce equipment costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

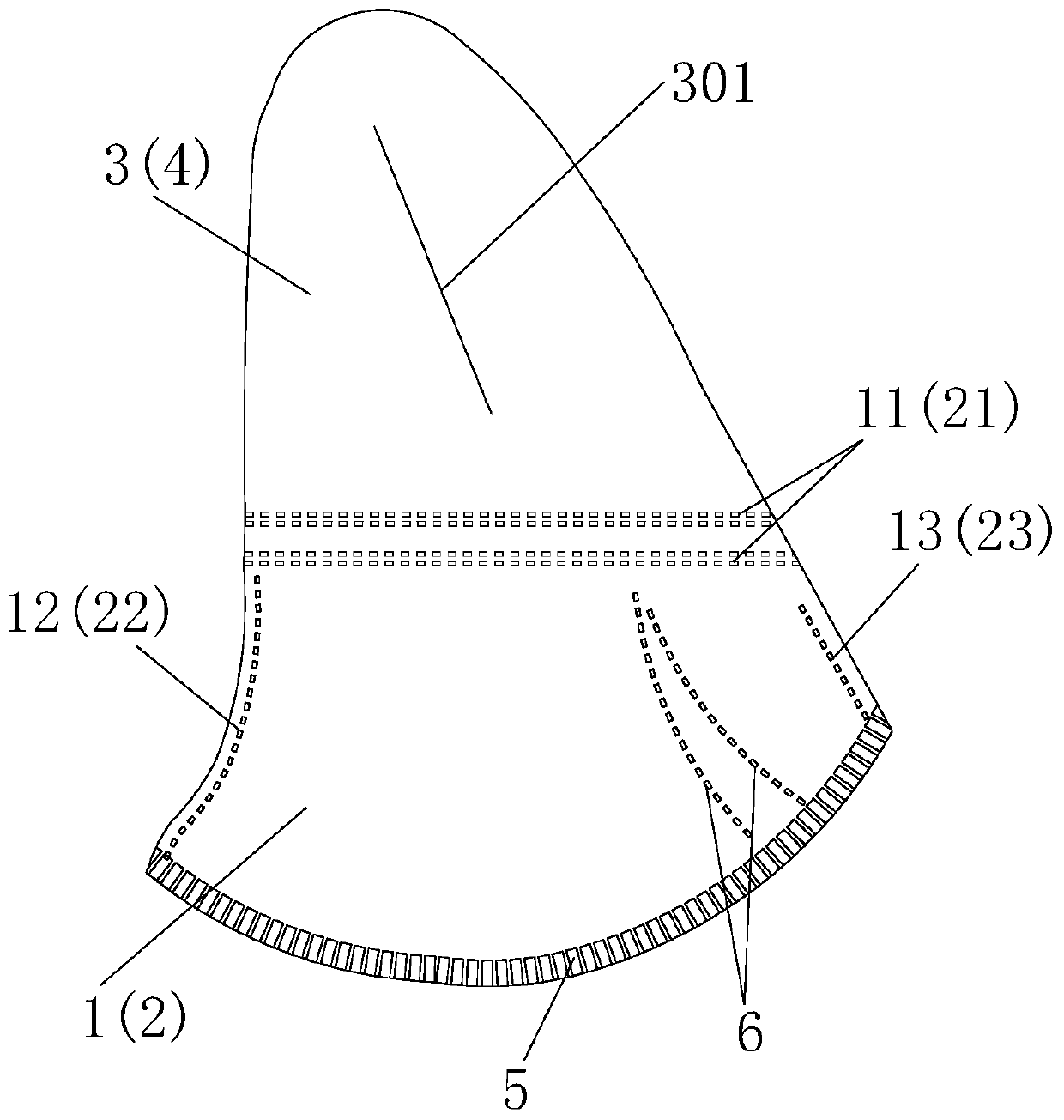

[0027] Such as Figure 1-Figure 2 Shown, what the present invention described is a kind of protective respirator without bridge of the nose, wherein: this protective respirator comprises the first mask body 1 and the second mask body 2 of symmetrical design, and the first ear strap cloth 3 that is symmetrically arranged and The second ear strap cloth 4, the first mask body 1 and the second mask body 2 respectively comprise an outer non-woven fabric, an inner layer non-woven fabric and at least one layer of melt blown cloth between the two, and the first ear strap The cloth 3 is embedded in the edge between the melt blown cloth of the first mask body 1 and the inner layer non-woven fabric and bonded by the first hot pressing line 11; the second ear strap cloth 4 is embedded in the melt blown cloth of the second mask body 2 The edge between the inner layer non-woven fabric is bonded by the second hot pressing line 21; the both side edges of the first mask body 1 are also provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com