All-working-condition gas-liquid separation device for satellite storage tank

A gas-liquid separation device and a technology of full working conditions, applied in the aerospace field, can solve the problems of increasing the cost of satellites, separate installation space, and inability to perform separation functions, and achieve the effect of simple structure, high structural strength, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

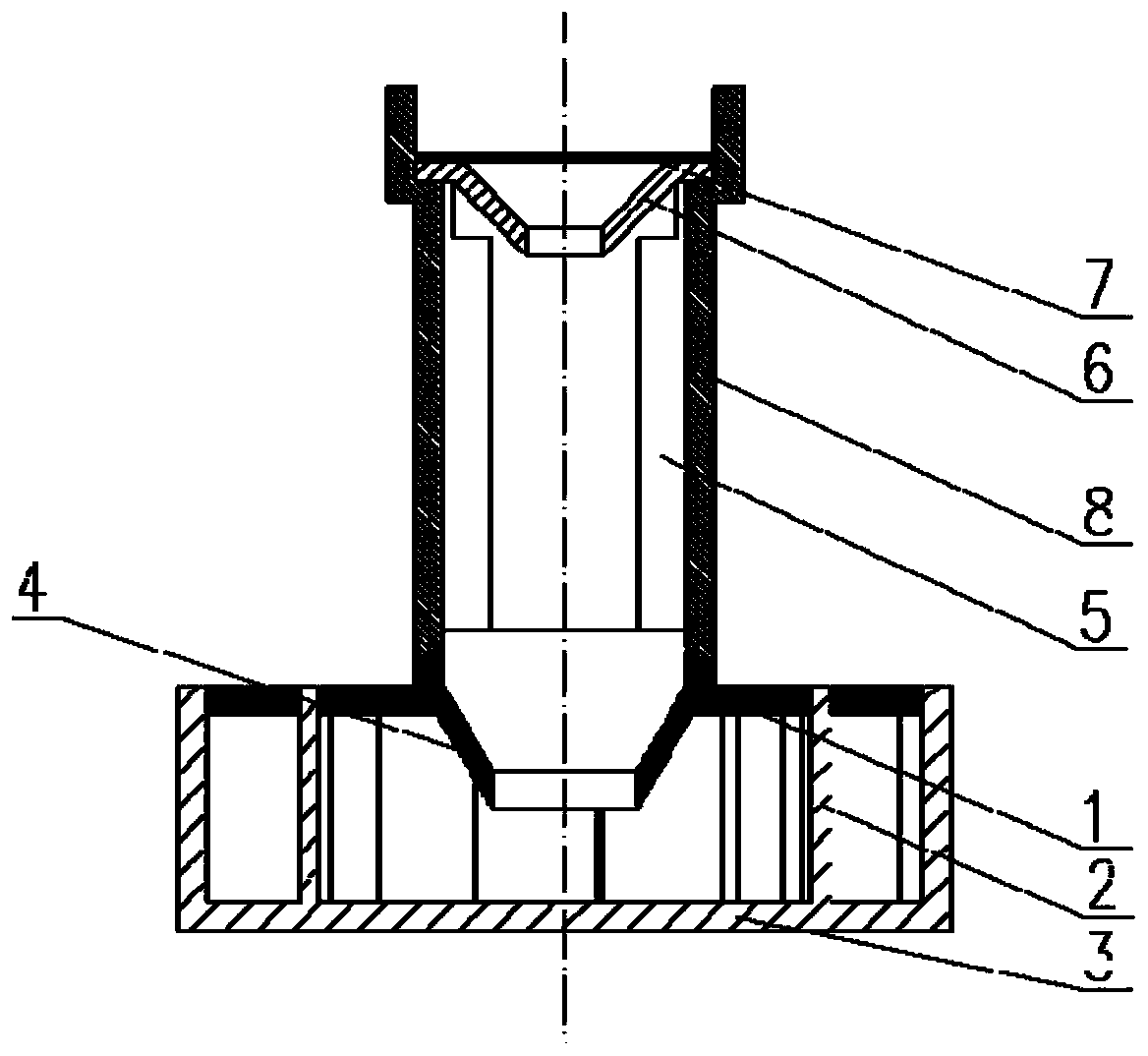

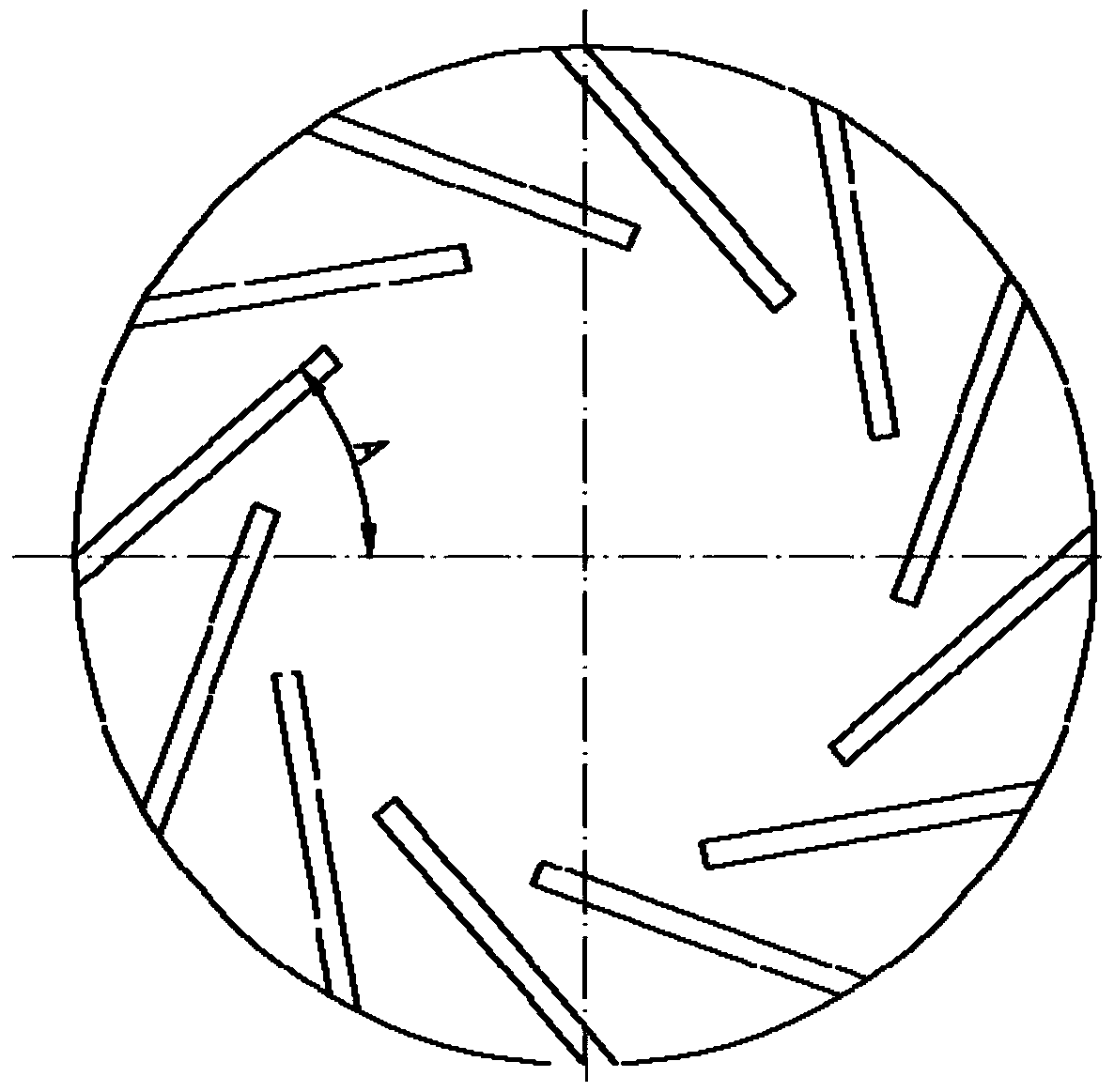

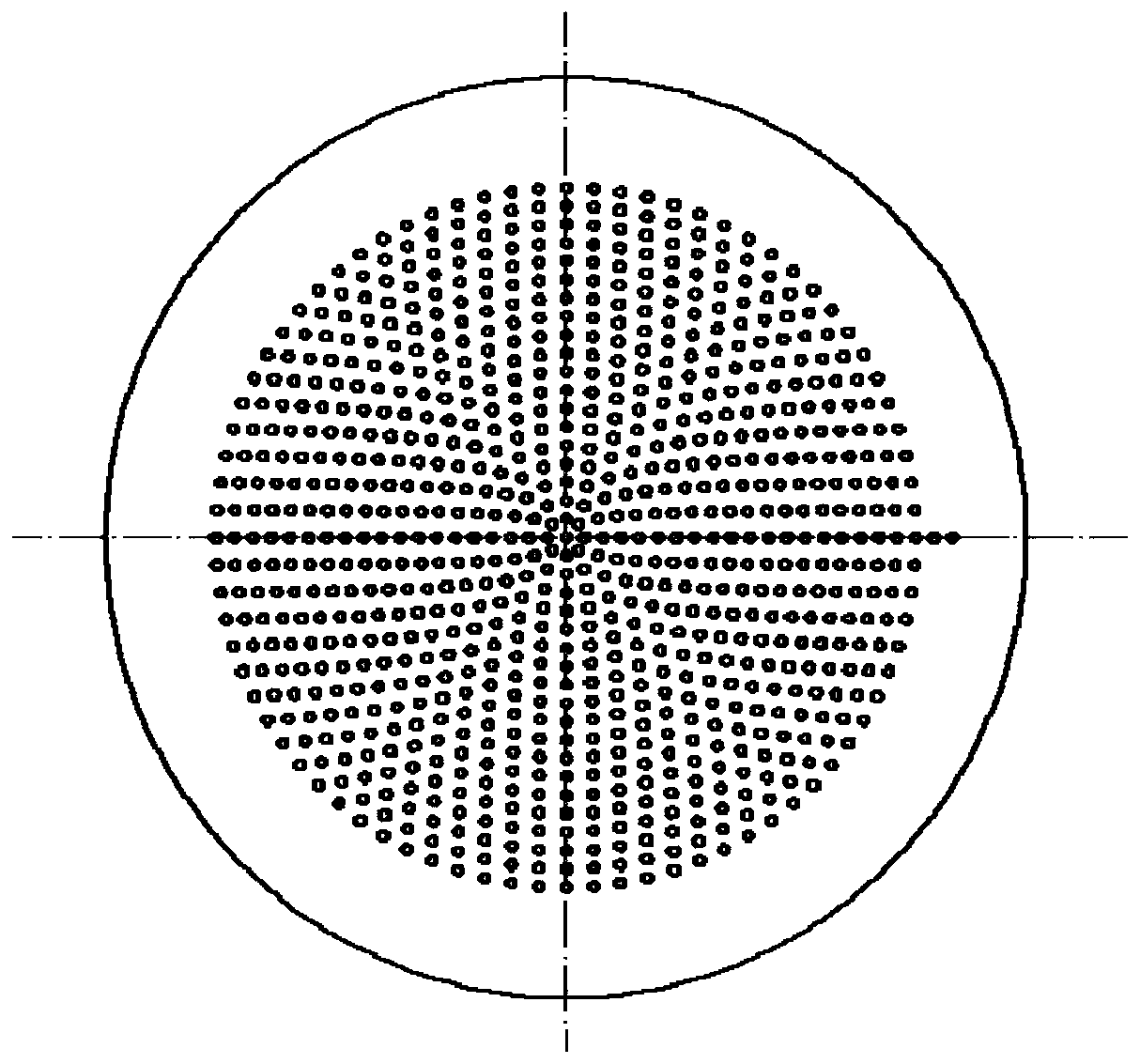

[0027] Such as figure 1 As shown, a gas-liquid separation device under full working conditions of a satellite storage tank includes: an upper cover plate 1, a centrifugal blade 2, a lower cover plate 3, a lower partition plate 4, a deflector plate 5, an upper partition plate 6, and a perforated plate 7. Cylindrical cavity 8; a plurality of centrifugal blades 2 are evenly distributed along the circumference, and are installed between the upper cover 1 and the lower cover 3; the cylindrical cavity 8 is installed in the center of the upper cover 1, and the cylindrical cavity 8 is connected to the centrifugal The cavities between the blades 2 are connected; the lower partition 4 is fixed on the lower end of the cylindrical cavity 8, and the deflector 5 is uniformly fixed on the inner wall of the cylindrical cavity 8 along the circumferential direction; the perforated plate 7 is installed on the upper partition 6, The perforated plate 7 and the upper baffle 6 are installed on the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap