A strip valve tray for preventing valve sticking

A float valve tray, float valve technology, applied in chemical/physical/physical chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of not being able to open freely, affecting the efficiency of the tray, and easy to stick the float valve and other problems, to avoid rust or adhesion, improve the efficiency of the tray, and achieve the effect of stable bubbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

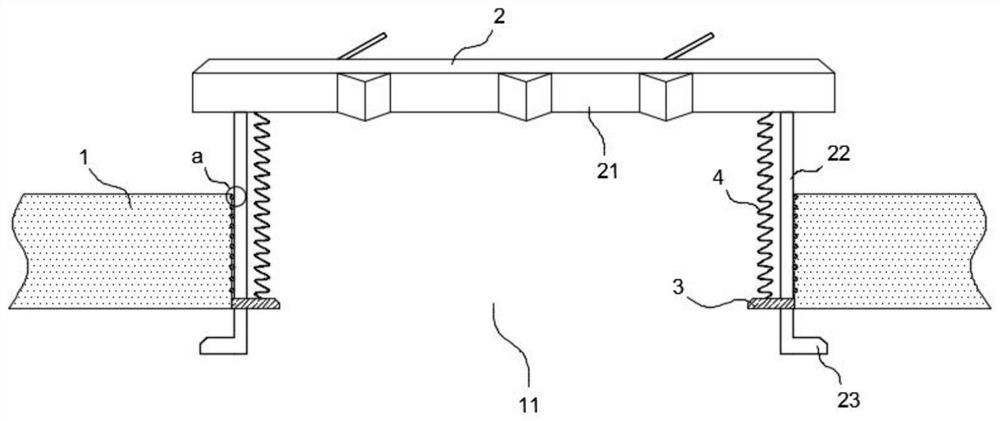

[0022] refer to figure 1 , the valve tray includes a valve tray plate body 1, the valve tray plate body 1 is provided with a valve hole 11, the valve hole 11 is opened as a rectangular channel, and the valve hole 11 is provided with a strip float valve 2 , the strip float valve 2 includes a rectangular valve cover 21 and two valve legs 22 .

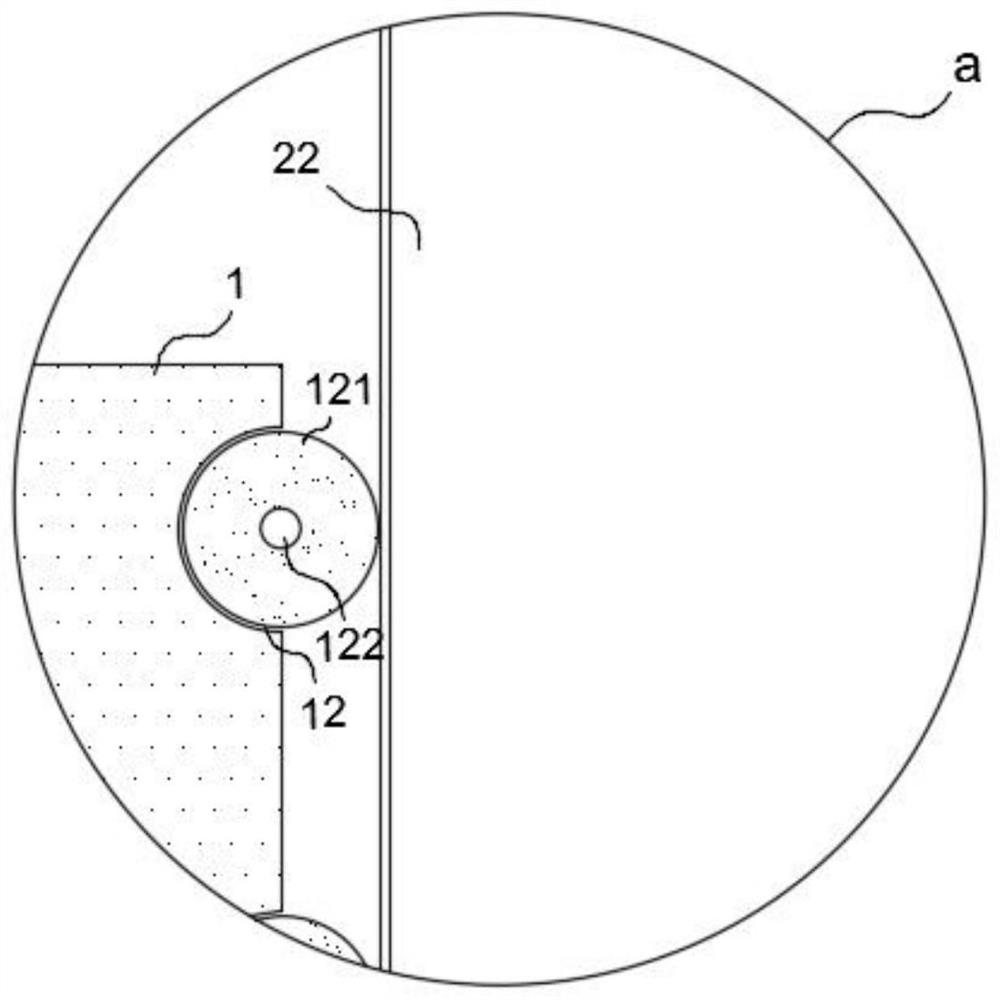

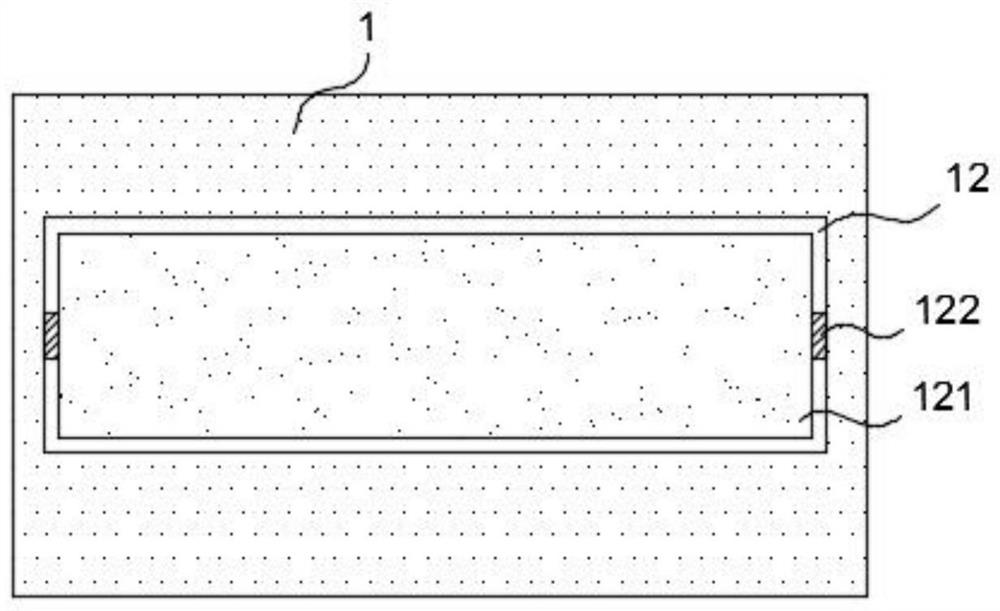

[0023] refer to figure 2 and image 3 , the side wall of the valve leg 22 joint of the valve tray plate body 1 and the strip float valve 2 is provided with a sliding groove 12, and the sliding groove 12 is opened into several along the vertical direction of the side wall of the valve tray body 1 , the sliding groove 12 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com