Coaxial propeller power system, coaxial double-propeller underwater propeller and aircraft

A power system and propeller technology, applied in the field of coaxial twin propeller underwater propellers and coaxial twin propeller aircraft, can solve the problems of mechanical application, lack of buoyancy, complex structure, etc., to achieve short axial length and reduce the problem of spin , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

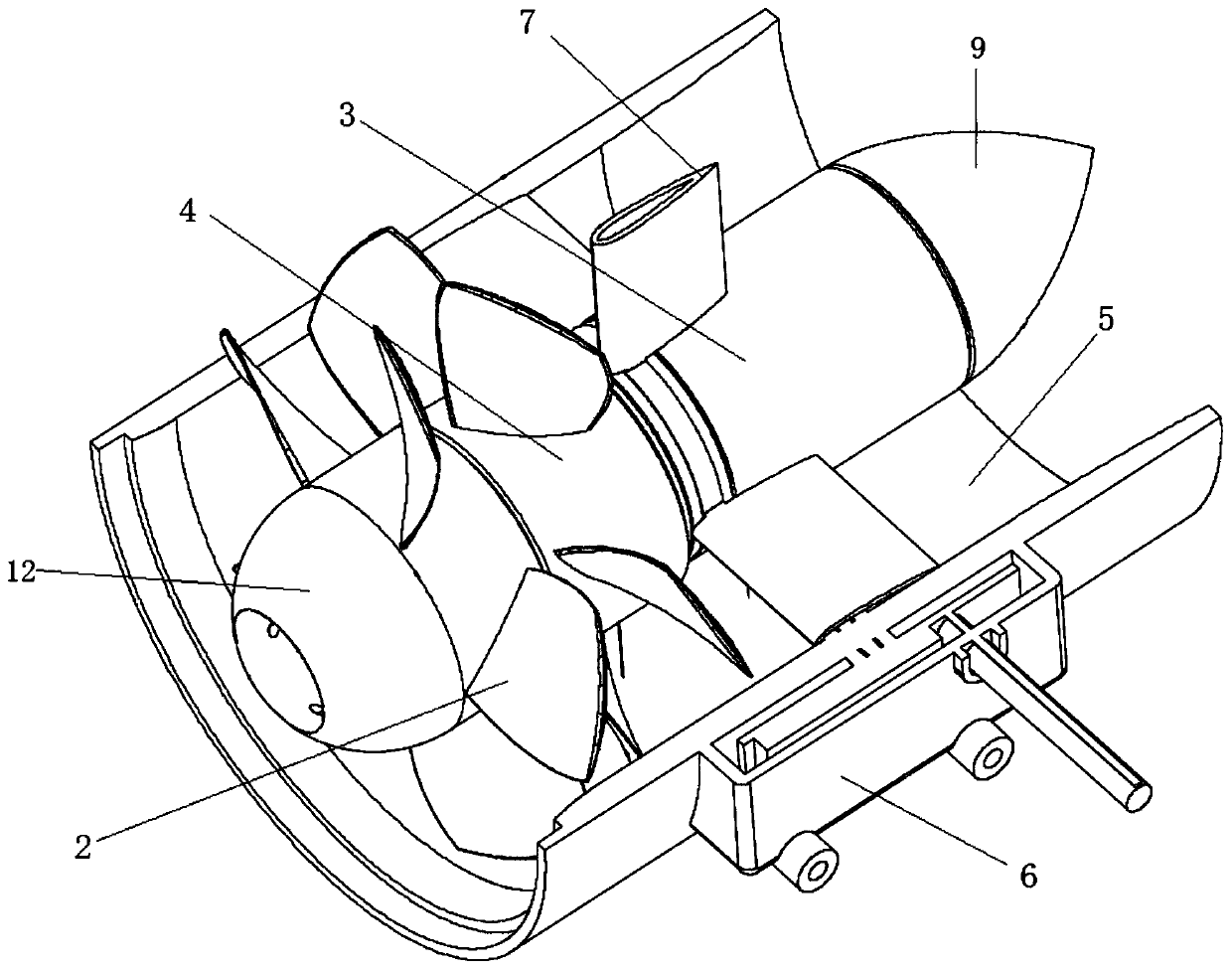

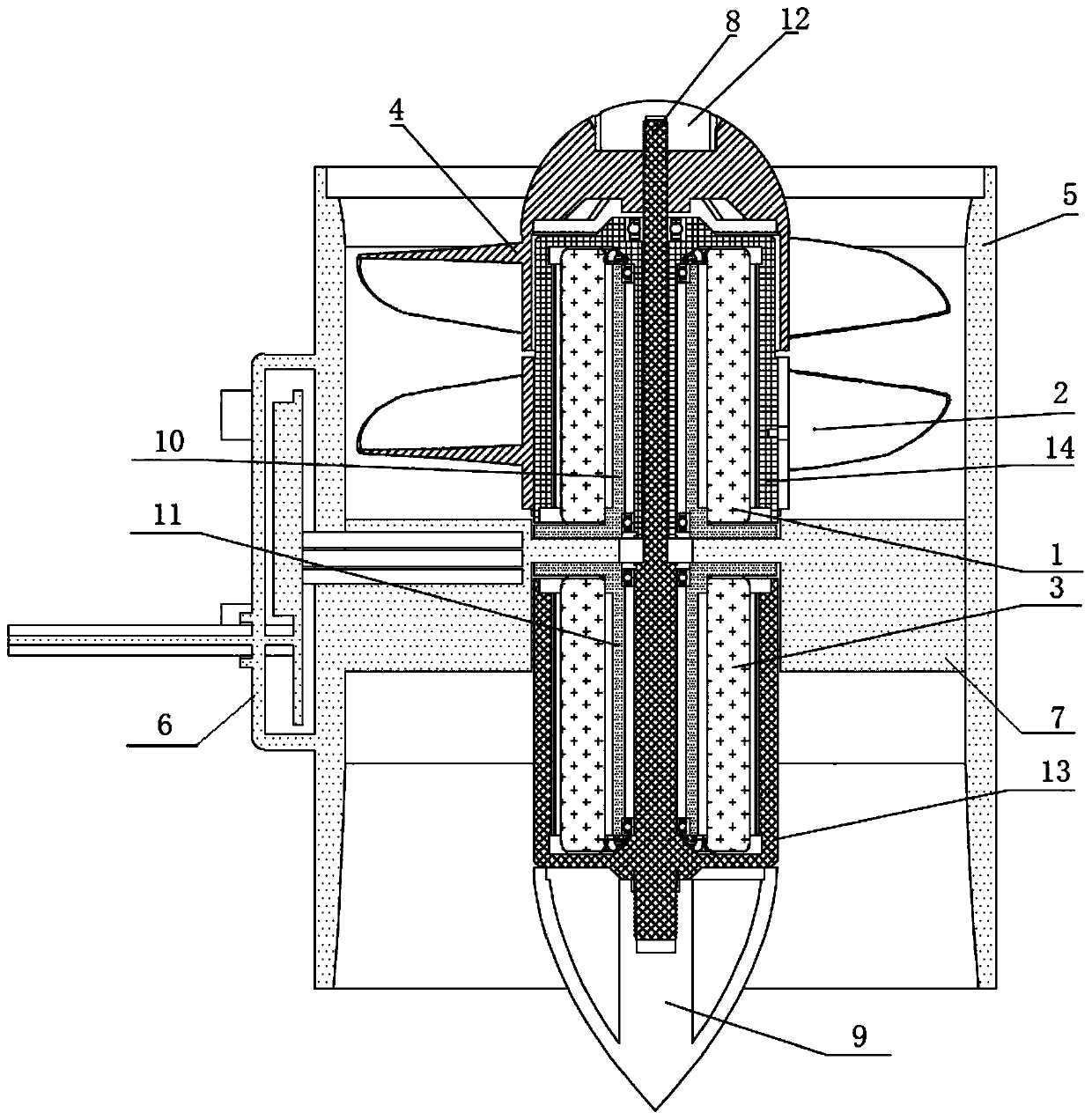

[0039] This embodiment provides a coaxial propeller power system, which is based on the coaxial double propeller technology of the aircraft and is designed in combination with the particularity of the underwater environment. Better motion accuracy and more stable attitude while obtaining more thrust, such as figure 1 , figure 2 As shown, specifically set to the following structure:

[0040] This kind of coaxial thruster power system is mainly for underwater equipment

[0041] Basically, the coaxial propeller power system includes a first blade drive system and a second blade drive system, and the first blade drive system and the second blade drive system are arranged in sequence along the propulsion direction.

[0042] The first blade drive system includes an upstream drive motor 1 and a first blade 2 arranged coaxially, and the second blade drive system includes a downstream drive motor 3 and a second blade 4 arranged coaxially.

[0043] For the first paddle drive system ...

Embodiment 2

[0055] On the basis of the above-mentioned embodiments, this embodiment further provides a coaxial double-bladed underwater propeller using the coaxial propeller power system, which can offset the spin of the propeller along the blade rotation direction to obtain better Accurate movement and a more stable attitude at the same time to obtain more thrust, especially the following configuration structure:

[0056] The coaxial double propeller underwater propeller adopting the coaxial propeller power system includes a control cabin, a propeller casing 5 and the coaxial propeller power system in Embodiment 1. Wherein, in this embodiment, the upstream driving motor 1 is specifically a shaftless outer rotor brushless DC motor, and the downstream driving motor 3 is specifically an inner rotor DC motor with a central shaft 8 . The propeller casing 5 is roughly a cylindrical structural member, forming a flow channel through the front and back, and the main control cabin 6 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com