Automatic shoveling and transporting equipment

A technology of transportation equipment and shoveling, which is applied in the field of automatic shoveling transportation equipment, which can solve the problems of large rotation angle, wear and damage of the rotating frame of the sand shovel, and achieve the effects of convenient output, prolonging service life and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

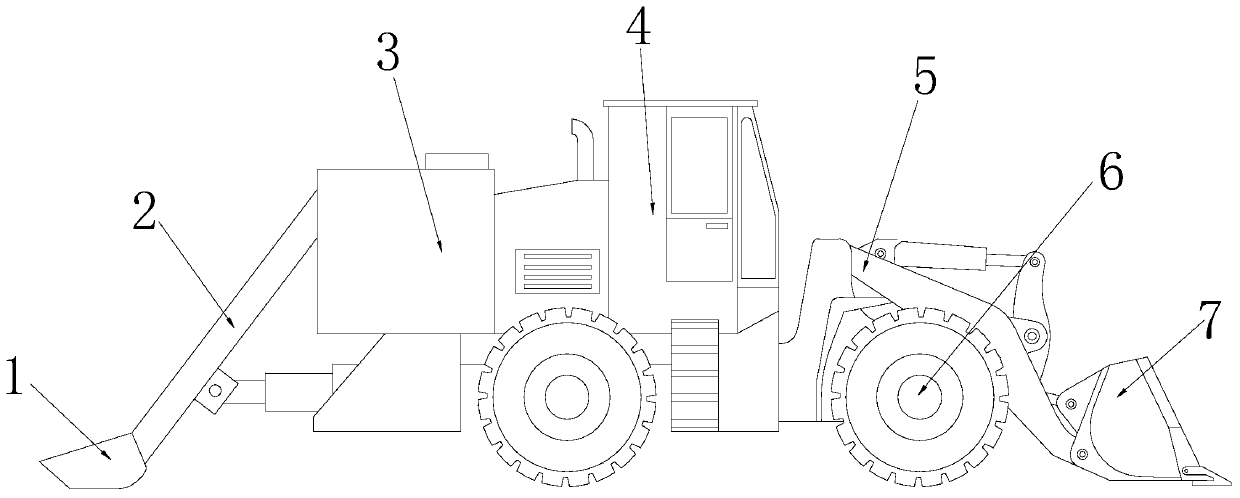

[0027] see Figure 1-Figure 6 , the present invention provides a kind of automatic shovel transportation equipment, its structure comprises small shovel 1, small shovel connecting rod 2, car body 3, cockpit 4, connecting frame 5, wheel 6, fork shovel 7, described small shovel 1 and The small shovel connecting rod 2 is mechanically connected, the small shovel connecting rod 2 is connected with the car body 3, the car body 3 is provided with a cockpit 4, the cockpit 4 is connected with the connecting frame 5, and the connecting The frame 5 is mechanically connected with the fork shovel 7, the fork shovel 7 is set up opposite to the small shovel 1, the bottom of the car body 3 is provided with wheels 6, and four of the wheels 6 are installed on the car body 3 respectively. corner bottom;

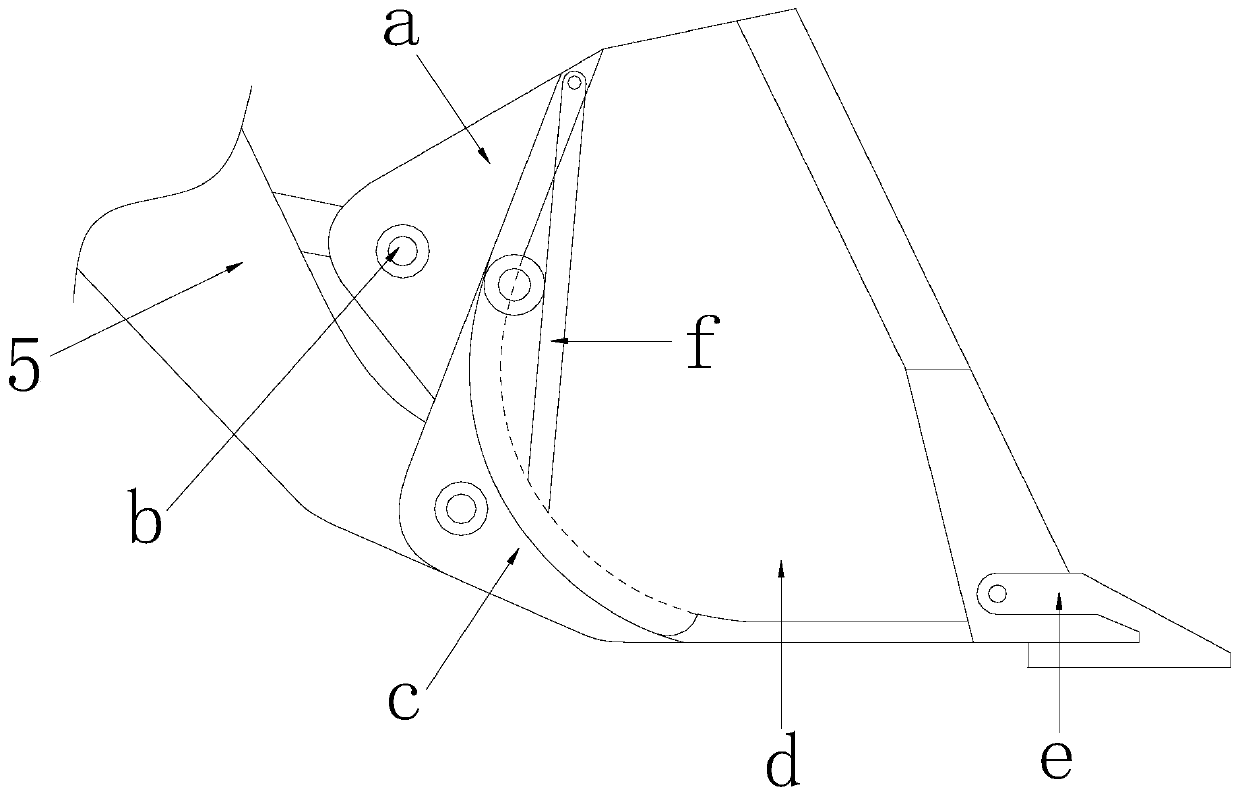

[0028] The fork shovel 7 is composed of a connecting block a, a fixed shaft b, a connecting frame c, a shovel d, a shovel head e, and a pushing plate f. The connecting block a is mechanically ...

Embodiment 2

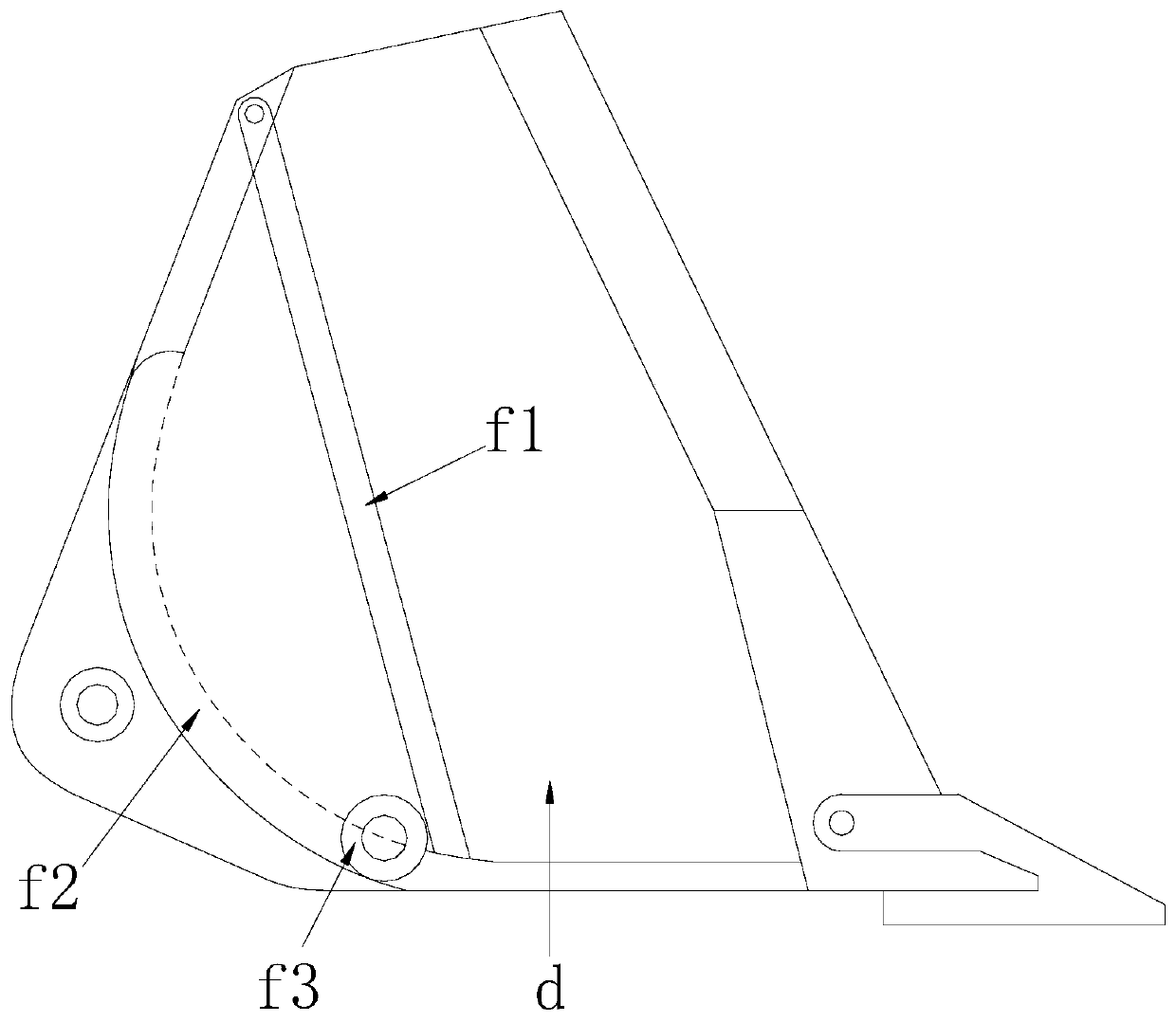

[0038] see Figure 1-Figure 4 , the present invention provides a kind of automatic shovel transportation equipment, its structure comprises small shovel 1, small shovel connecting rod 2, car body 3, cockpit 4, connecting frame 5, wheel 6, fork shovel 7, described small shovel 1 and The small shovel connecting rod 2 is mechanically connected, the small shovel connecting rod 2 is connected with the car body 3, the car body 3 is provided with a cockpit 4, the cockpit 4 is connected with the connecting frame 5, and the connecting The frame 5 is mechanically connected with the fork shovel 7, the fork shovel 7 is set up opposite to the small shovel 1, the bottom of the car body 3 is provided with wheels 6, and four of the wheels 6 are installed on the car body 3 respectively. corner bottom; the fork shovel 7 is composed of connecting block a, fixed shaft b, connecting frame c, shovel groove d, shovel head e, and push plate f; the shovel head e is guided by connecting plate e1, shove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com