A kind of continuous rib anchor rod steel and its preparation method

A technology of bolt steel and transverse ribs, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve the problems of poor anchoring force, large deformation and easy occurrence of microcracks at the gaps at the ends of transverse ribs, etc., and achieves Improve the anchoring effect, reduce the generation of micro-cracks, and increase the effect of anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

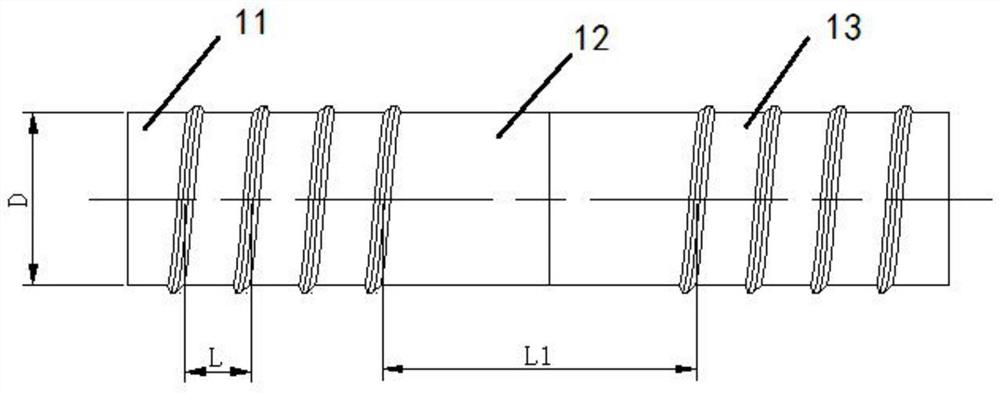

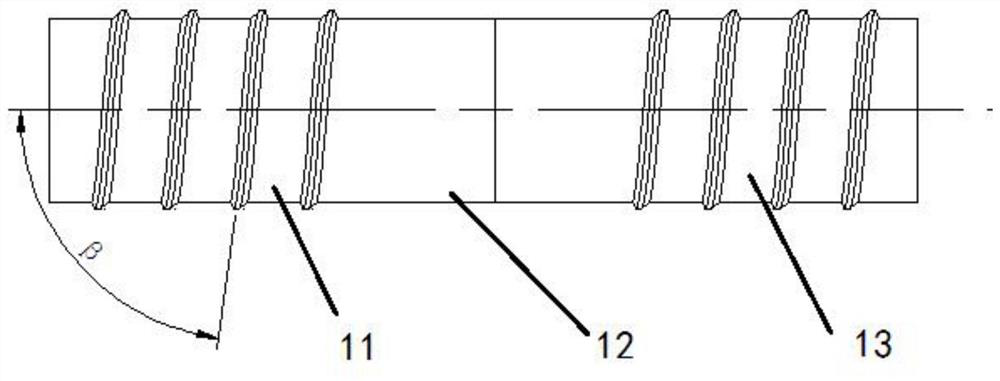

[0033] figure 1 It is a structural schematic diagram of a continuous rib anchor steel in the embodiment of the present invention, as figure 1 As shown, the continuous rib anchor steel includes:

[0034] The rod body 1, the rod body 1 includes: a first transverse rib section 11; a first straight section 12, the first straight section 12 is located at the end of the first transverse rib section 11; a second transverse rib section 13, The second transverse rib section 13 is located at the end of the first straight section 12 ; wherein, the outer surfaces of the first transverse rib section 11 and the second transverse rib section 13 are provided with threads 4 .

[0035] Further, the thread 4 is a left-handed thread, or a right-handed thread.

[0036] Further, the thread 4 is a continuous equal-height thread.

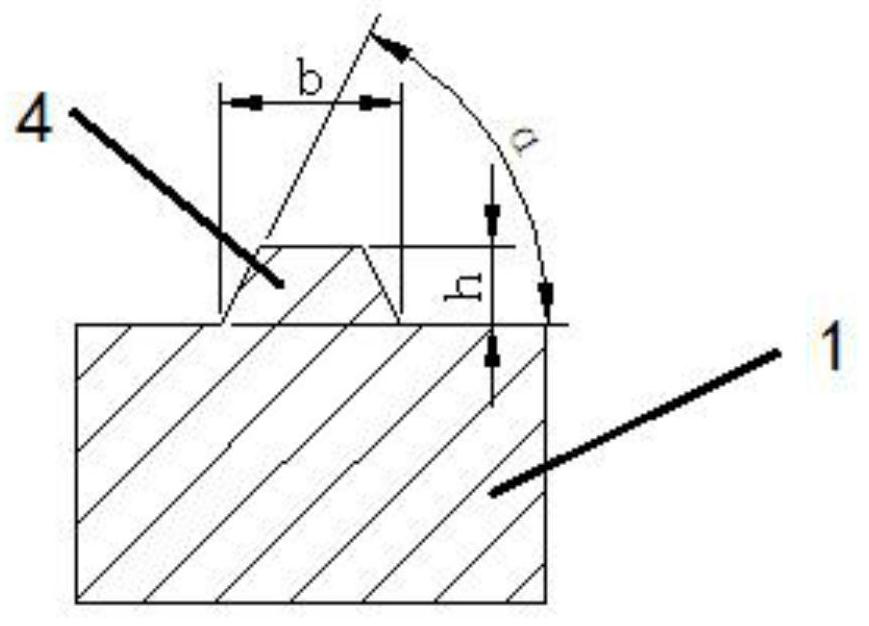

[0037] Specifically, as image 3 , 4As shown, the rod body 1 is the main external structure of the continuous rib anchor rod steel, and its shape is a long cylindrica...

Embodiment 2

[0051] Figure 8 It is a schematic flow chart of a preparation method of continuous rib anchor steel in the embodiment of the present invention, as Figure 8 As shown, the method includes:

[0052] Step 1: Start the roll turning, and use the lathe to turn the rolled piece out of the first pass structure according to the first preset requirements.

[0053] Specifically, after the pass pattern of the continuous rib anchor steel is designed, the roll turning can then be started. First, the first pass structure is turned on the CNC lathe according to the first preset requirements, that is to say, Such as Figure 5 As shown, according to the "pass pattern at the ribbed part", that is, the first inner circle 21 in the first pass structure is driven out of the pass pattern.

[0054] Step 2: using a milling machine to mill out threads 4 on the rolled piece according to preset requirements.

[0055] Specifically, as Figure 7 As shown, make a transverse rib milling cutter accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com