Method for improving rotation stress stripe level value of epoxy resin photoelastic model

A technology of epoxy resin and photoelasticity, which is applied in the field of photoelasticity testing, can solve the problems of similarity principle and test accuracy to be improved, and achieve the effects of low equipment loading capacity, high precision, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

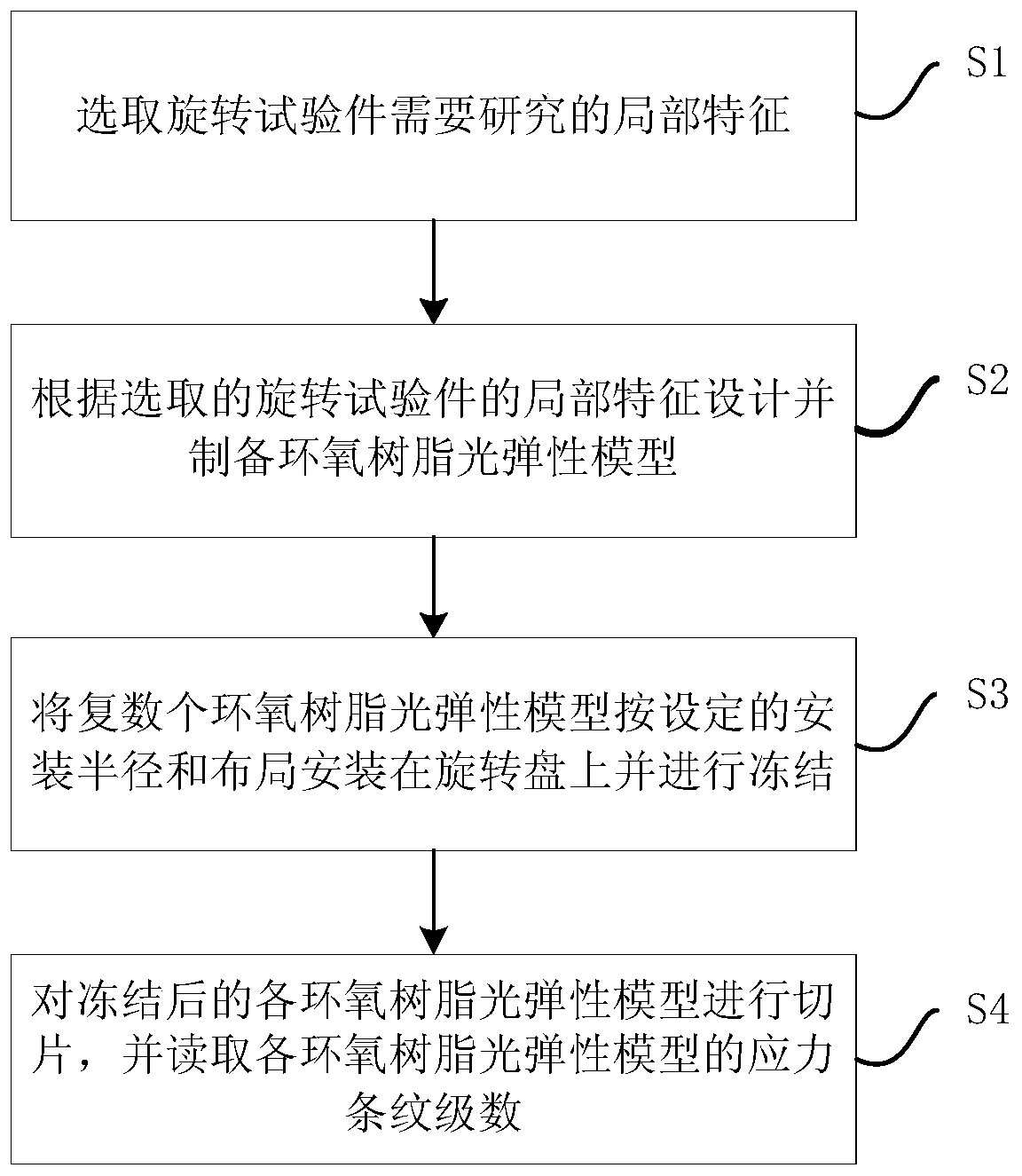

[0032] refer to figure 1 , the preferred embodiment of the present invention provides a kind of method that improves epoxy resin photoelastic model rotational stress fringe level numerical value, comprises steps:

[0033] S1. Select the local features of the rotating test piece to be studied;

[0034] S2. Design and prepare an epoxy resin photoelastic model according to the local characteristics of the selected rotating test piece;

[0035] S3. Installing multiple epoxy resin photoelastic models on the rotating disk according to the set rotation radius and layout and freezing them;

[0036] S4. Slicing each frozen epoxy resin photoelastic model, and reading the stress fringe series of each e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap