Motor controller full-automatic testing device

A fully automatic testing and motor controller technology, applied in electrical testing/monitoring, program control, general control systems, etc., can solve problems such as low production efficiency, potential safety hazards, inability to meet actual production capacity, etc., to achieve convenient operation and ensure normal operation. Use and facilitate the effect of motor performance testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

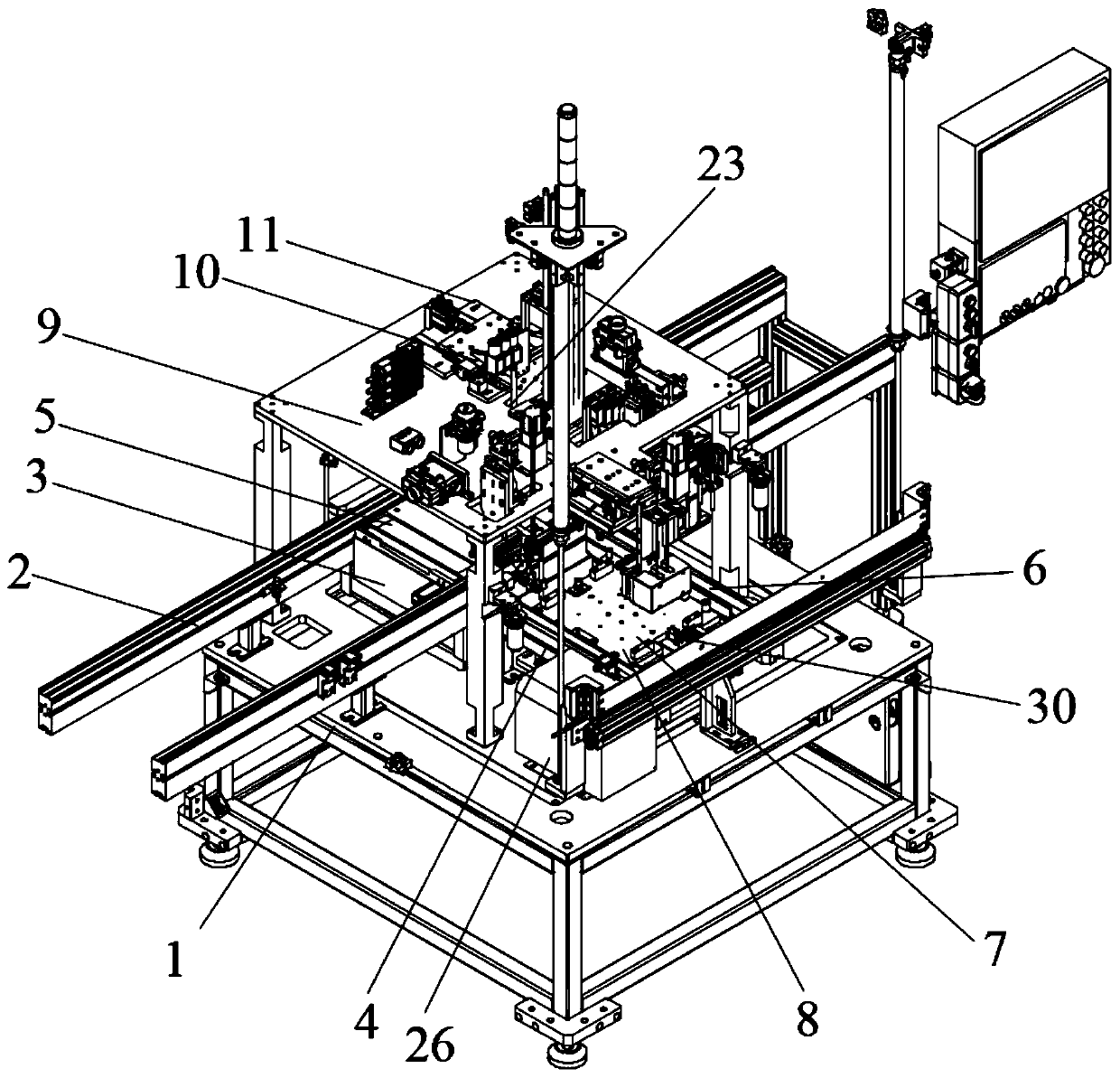

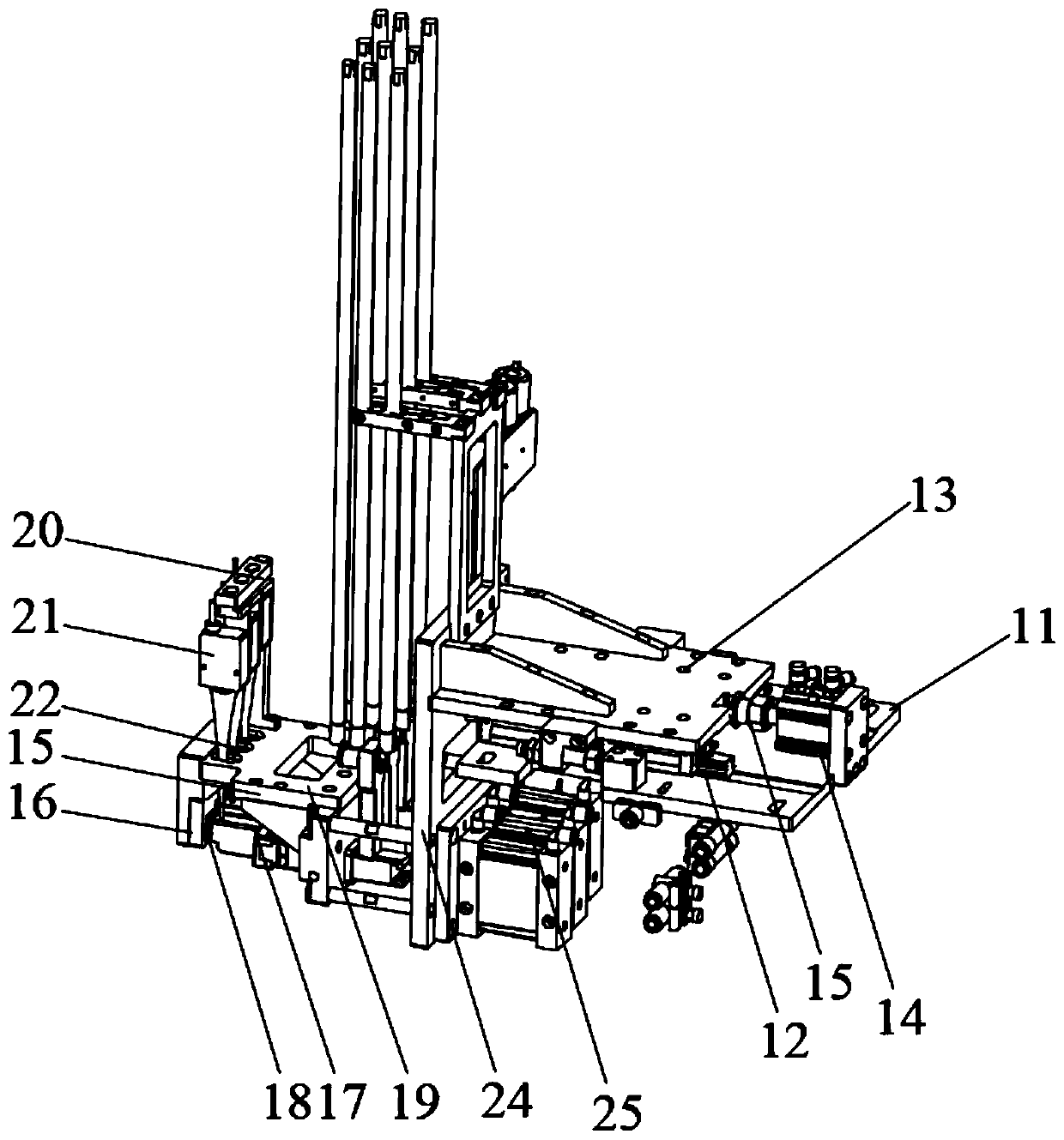

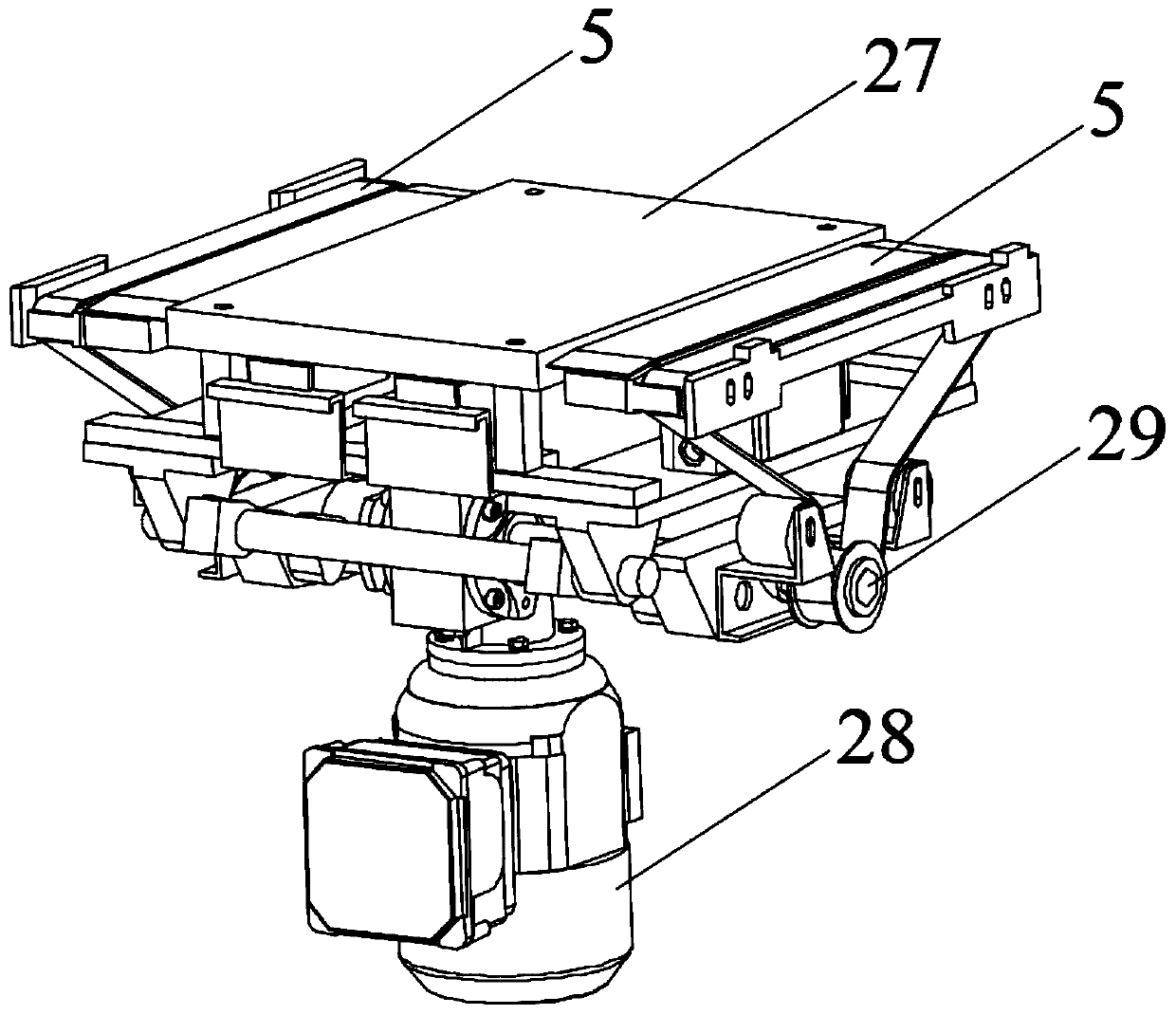

[0017] Such as Figure 1 ~ Figure 4 As shown, the present invention includes a frame 1, a streamline track 2 is arranged at one end of the frame 1, and a traverse mechanism 3 perpendicular to the direction of motion is provided at the streamline track 2, and the frame 1 is in addition One end is provided with conveyer 4, and described traversing mechanism 3 is identical with the moving direction of described conveyer 4, and described traversing mechanism 3 comprises traversing conveyer belt 5, and the conveyer belt 6 of described conveyer 4, traversing conveying The installation heights of the belt 5 and the streamline track 2 are consistent, and the frame 1 located at the conveyor 4 is provided with a jacking mechanism 8, and the jacking mechanism 8 includes a jacking plate 7, and the jacking plate 7 The lower part is connected with a jacking cylinder (not shown in the figure) mounted on the frame 1, a tooling seat 9 is arranged above the traverse mechanism 3, and a plug dock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com