Pair of self-adaptive labor-saving crimping pliers

A labor-saving, crimping pliers technology, applied in the direction of line/collector parts, manufacturing tools, electrical components, etc., can solve the problems of no self-adaptive function, large volume of crimping pliers, cumbersome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

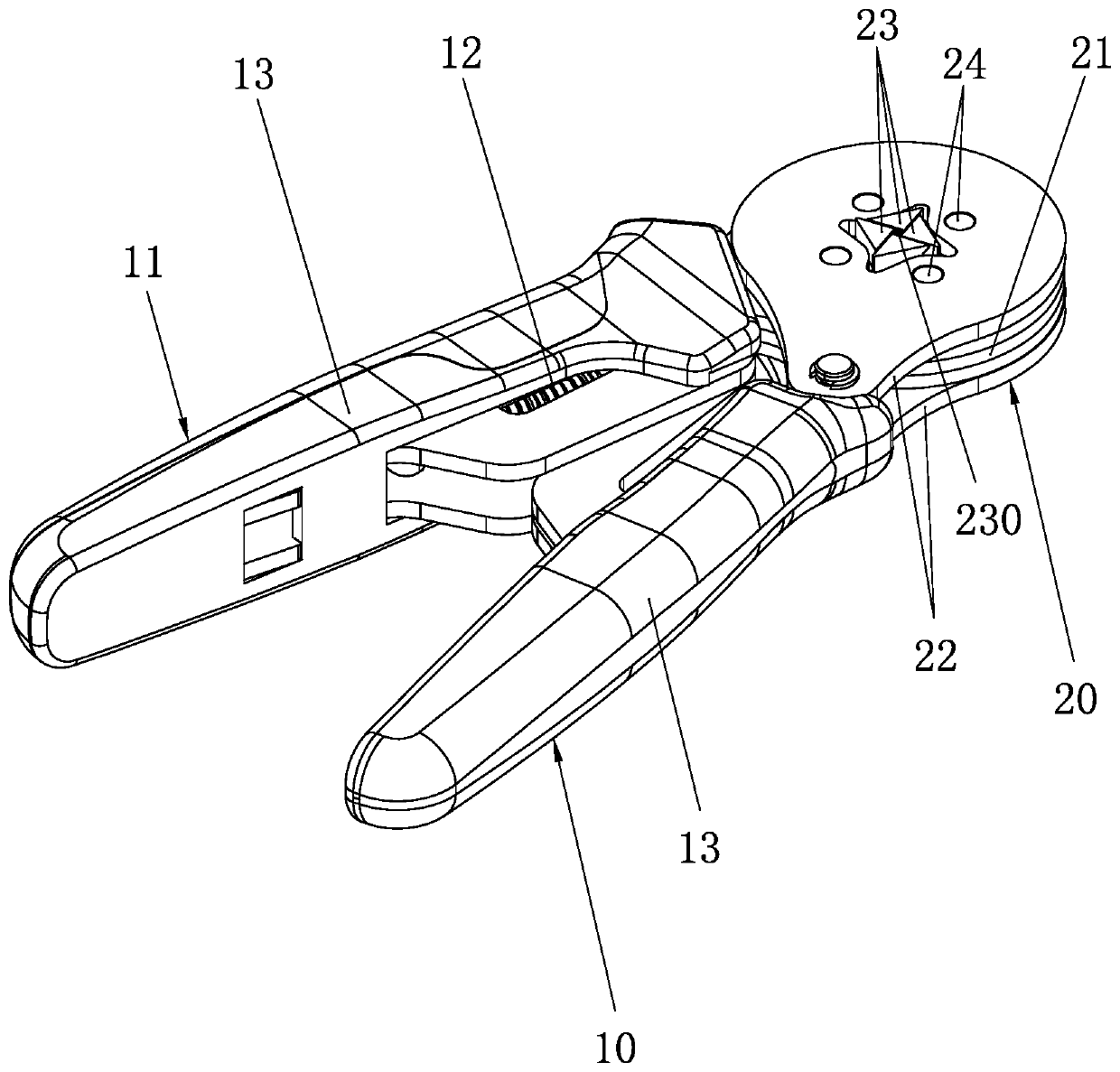

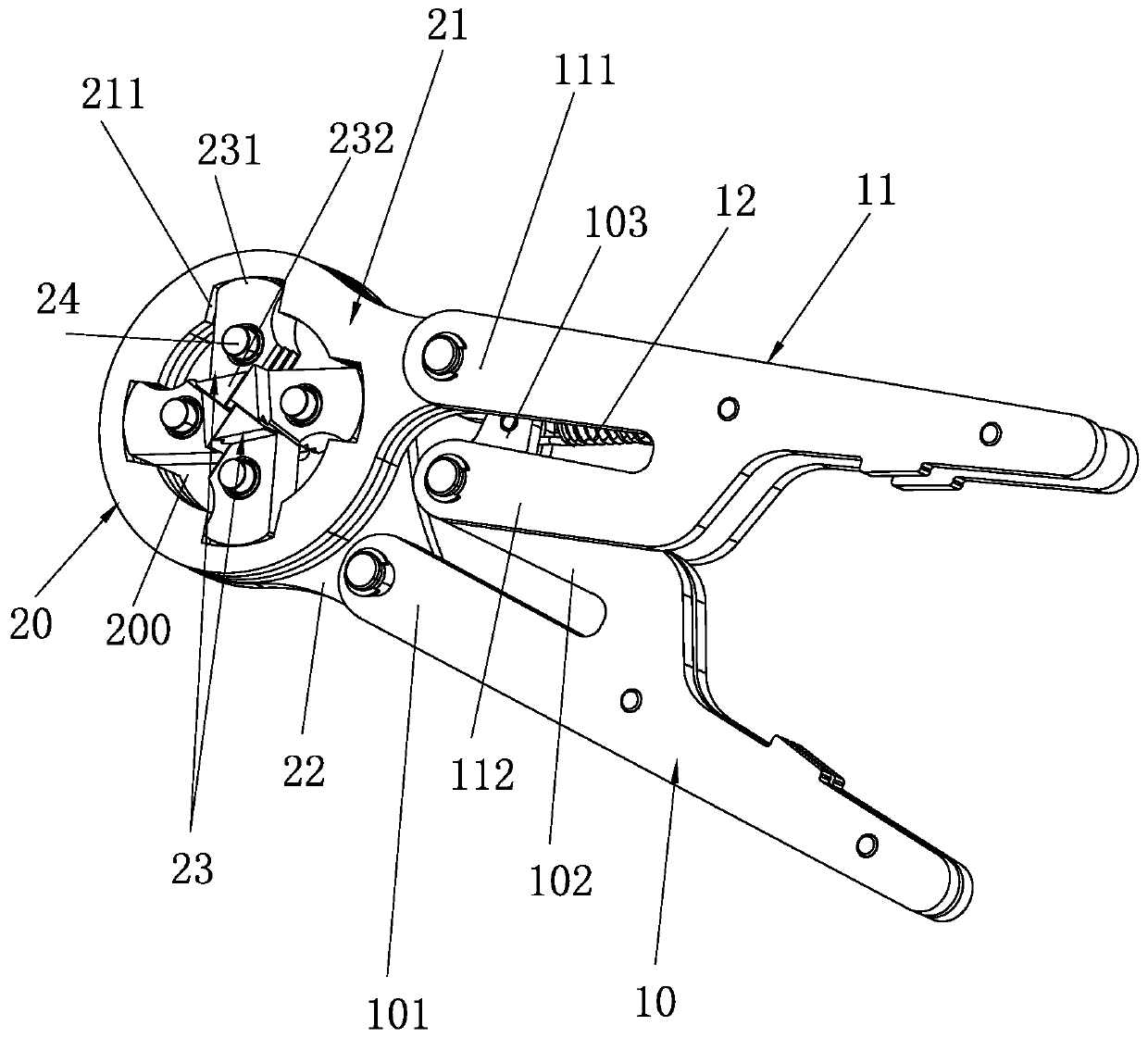

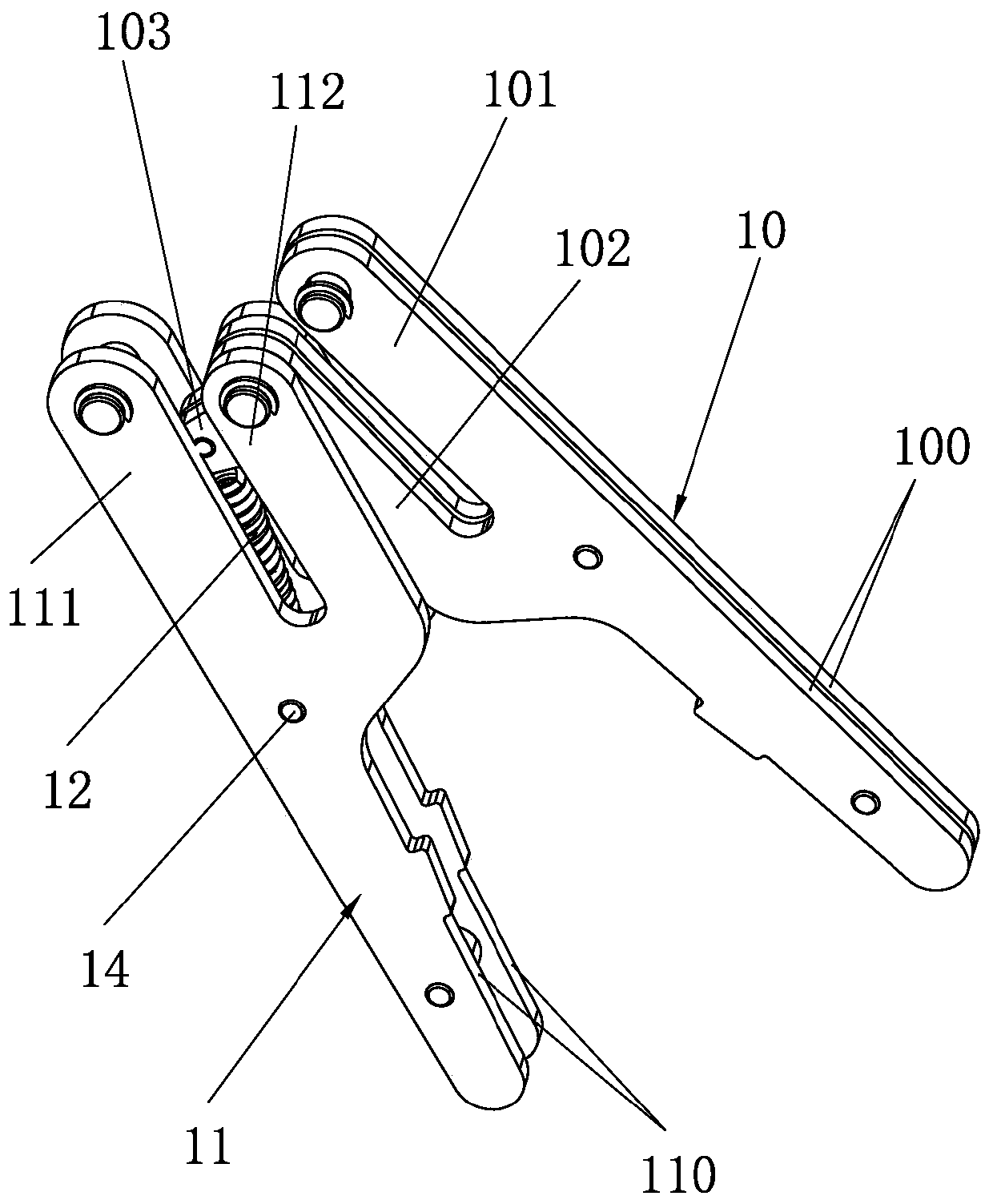

[0013] Such as Figure 1~4 As shown, the embodiment of the present invention is a self-adaptive labor-saving crimping pliers, comprising a long handle 10, a moving handle 11, a pliers head 20 arranged on one end of the long handle 10 and the moving handle 11, the long handle 10 One end has a bifurcation and is respectively formed with a connecting arm 101 and an elastic support arm 102. The connecting arm 101 is rotatably arranged on the pliers head 20 and forms a linkage between the long handle 10 and the pliers head 20. The moving handle 11 One end has a bifurcation and is respectively formed with a moving connecting arm 111 and an elastic driving arm 112. The moving connecting arm 111 is rotatably arranged on the pliers head 20 and constitutes a linkage between the moving handle 11 and the pliers head 20. The elastic The driving arm 112 is rotatably arranged on the elastic support arm 102 and constitutes the rotational connection and cooperation between the moving handle 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com