Electric wire pliers for aerial work

A high-altitude operation and wire technology, applied in the installation of pliers, electrical components, cables, etc., can solve the problems of the influence of the conductive efficiency of the rubber insulated wire and the fracture of the inner core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

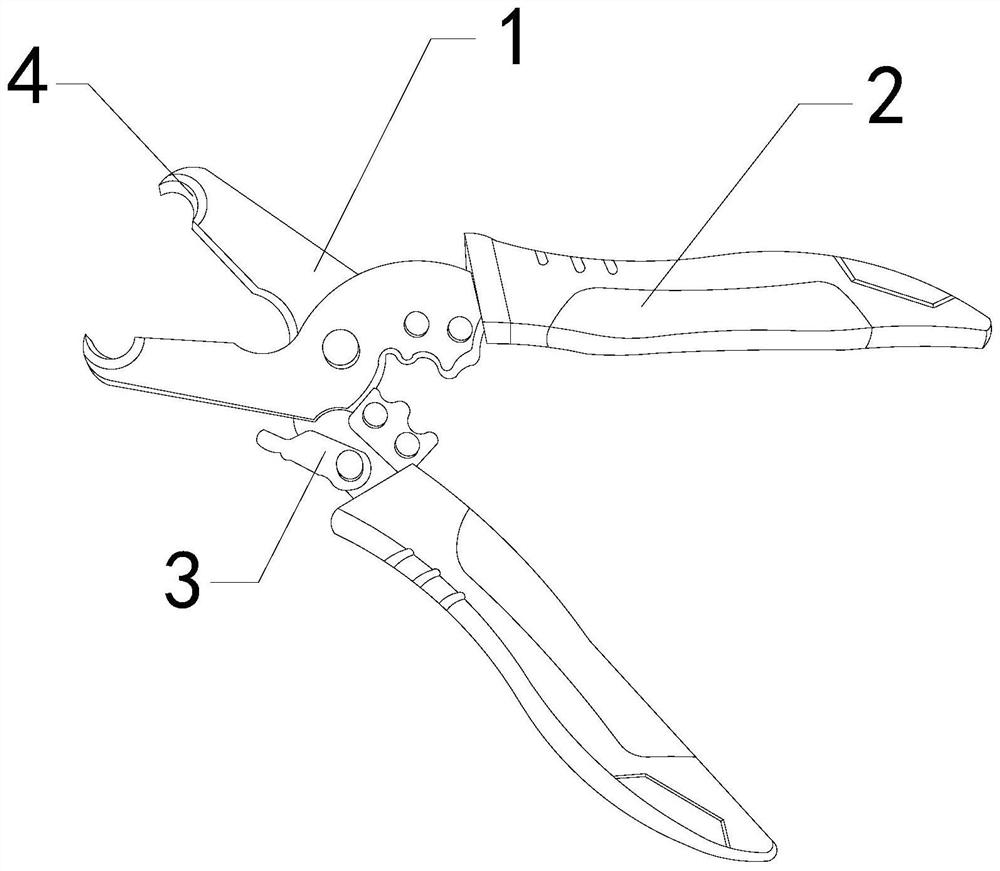

[0027] For example figure 1 -example Figure 5 Shown:

[0028] The invention provides a wire pliers for high-altitude operation, the structure of which includes a jaw 1, a handle 2, a limit block 3, and a circumcision mechanism 4. The jaw 1 and the handle 2 are embedded and connected, and the limit block 3 Engaging with the pliers mouth 1 movably, the circumcision mechanism 4 and the pliers mouth 1 are an integrated structure.

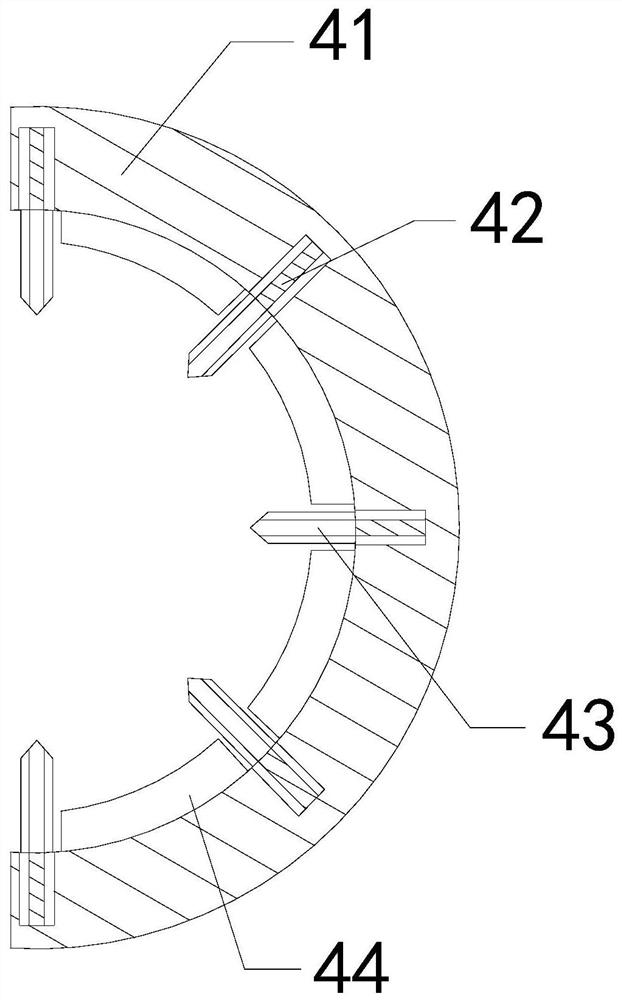

[0029] Wherein, the circumcision mechanism 4 includes an outer frame 41, a housing groove 42, a peeling mechanism 43, and a fixing block 44, the housing groove 42 and the outer frame 41 are an integrated structure, and the peeling mechanism 43 is installed in the housing groove 42. At the front end position, the fixed block 44 is embedded in the left surface position of the outer frame 41, and the inside of the accommodating groove 42 is hollowed out on both sides, so that the solid block in the middle can be connected with the peeling mechanism 43, ...

Embodiment 2

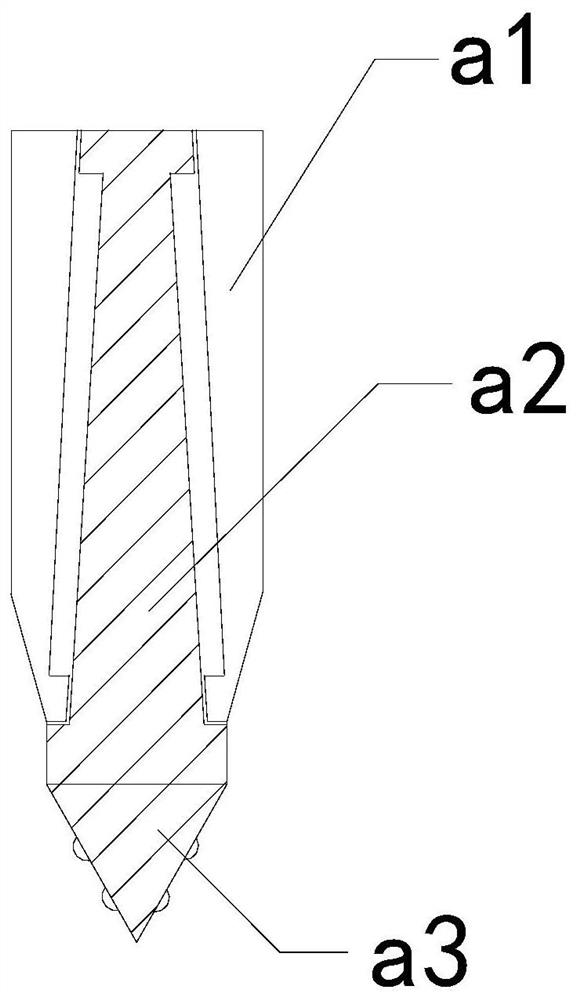

[0036] For example Figure 6 -example Figure 8 Shown:

[0037] Wherein, the piercing head a3 includes a housing a31 and a cutting ring a32, the cutting ring a32 is movably engaged with the housing a31. The left and right sides of the housing are symmetrically distributed, which is beneficial for the shell a31 to pierce the rubber insulation on the wire.

[0038]Wherein, the cutting ring a32 includes a cut-off piece c1, a joint ring c2, and a central axis c3, the cut-off piece c1 is embedded and connected to the joint ring c2, and the inner surface of the joint ring c2 is attached to the outer surface of the central axis c3 , the cut-off piece c1 is provided with sixteen pieces, and is evenly distributed in a circular shape on the outer surface of the joint ring c2. When the cut-off piece c1 is pushed upward by the rubber insulation, the joint ring c2 can be moved along the central axis c3 Rotate, so that the rotating cutting piece c1 can continuously cut the rubber insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com