Processing machine for graphene elastic mesh reinforced carbon fiber fishing rod

A graphene and carbon fiber technology, applied in the field of fishing rods, can solve the problems of uneven distribution of graphene, prone to bubbles, agglomeration and difficulty in dispersing, etc., and achieve the effect of avoiding local fracture and improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

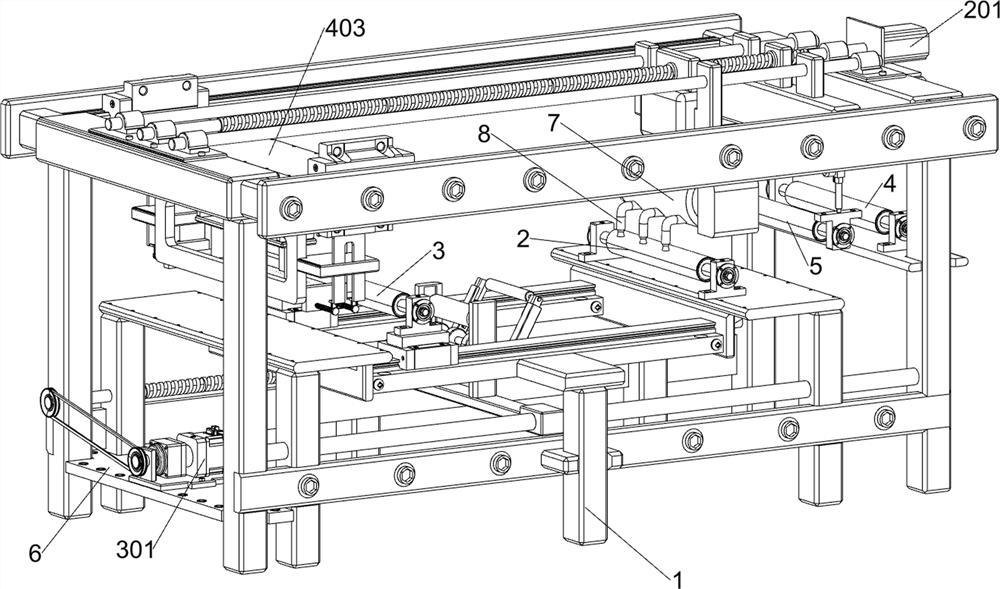

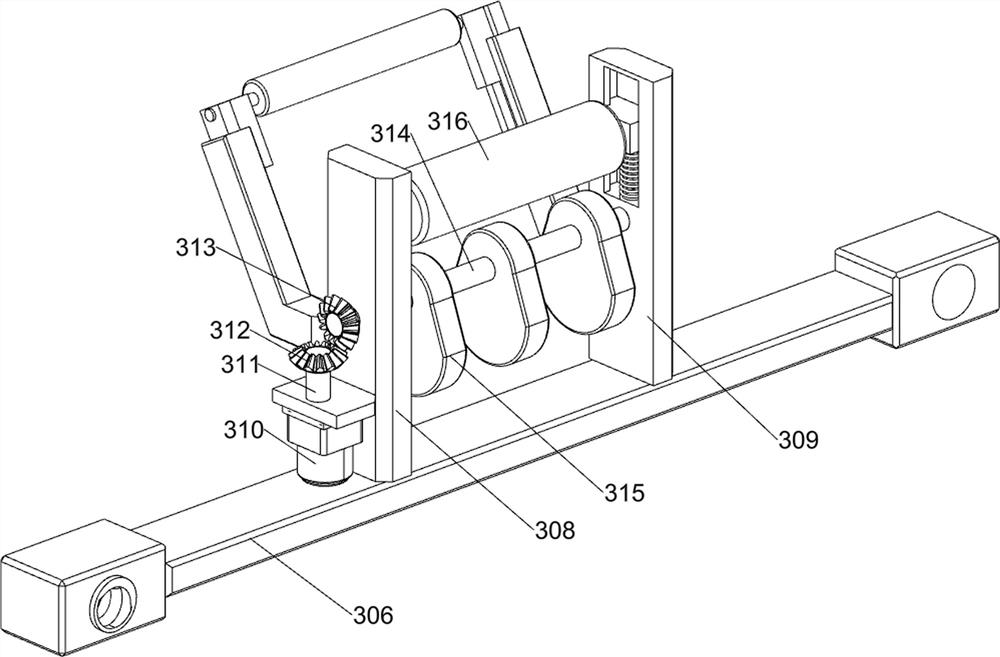

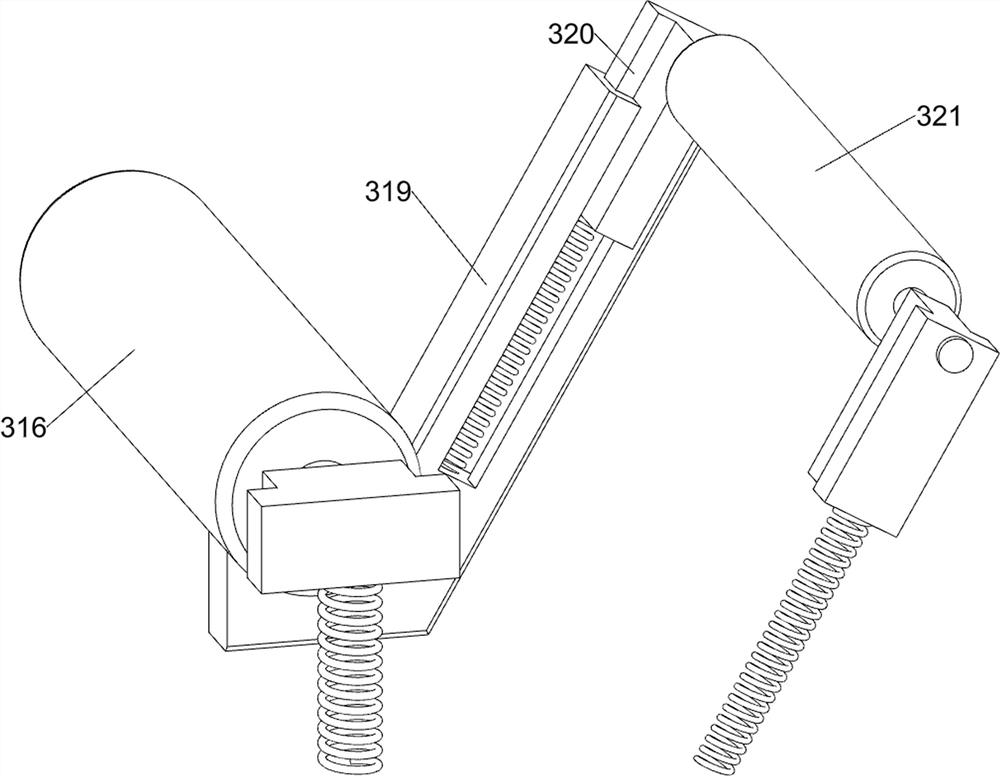

[0033] A graphene elastic mesh reinforced carbon fiber fishing rod processing machine, according to Figure 1-3 As shown, it includes a bottom plate assembly 1, a first turning roller 2, a third turning roller 4, a first support plate 6, a compacting unit and a defoaming unit; the bottom plate assembly 1 is fixedly connected to the first turning roller 2; the bottom plate assembly 1 is fixedly connected with the third rotating roller 4; the bottom plate assembly 1 is fixedly connected with the first support plate 6; a compacting unit is arranged in the bottom plate assembly 1; a defoaming unit is installed in the bottom plate assembly 1; the first support plate 6 is connected with The compaction unit is fixed; the compaction unit compacts the graphene elastic mesh and the release paper to bond the two, and squeezes out the excess epoxy resin, and the defoaming unit compacts the compaction unit and bonds them The graphene elastic mesh cloth and the air bubbles inside the releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com