Bilateral synchronous scribing device for glass processing

A scribing device and glass technology, which is applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems affecting the quality of suede glass products, affecting the separation of suede glass, and breaking of suede glass, so as to prevent cutting surfaces No, to avoid unqualified shape and increase the effect of scribing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

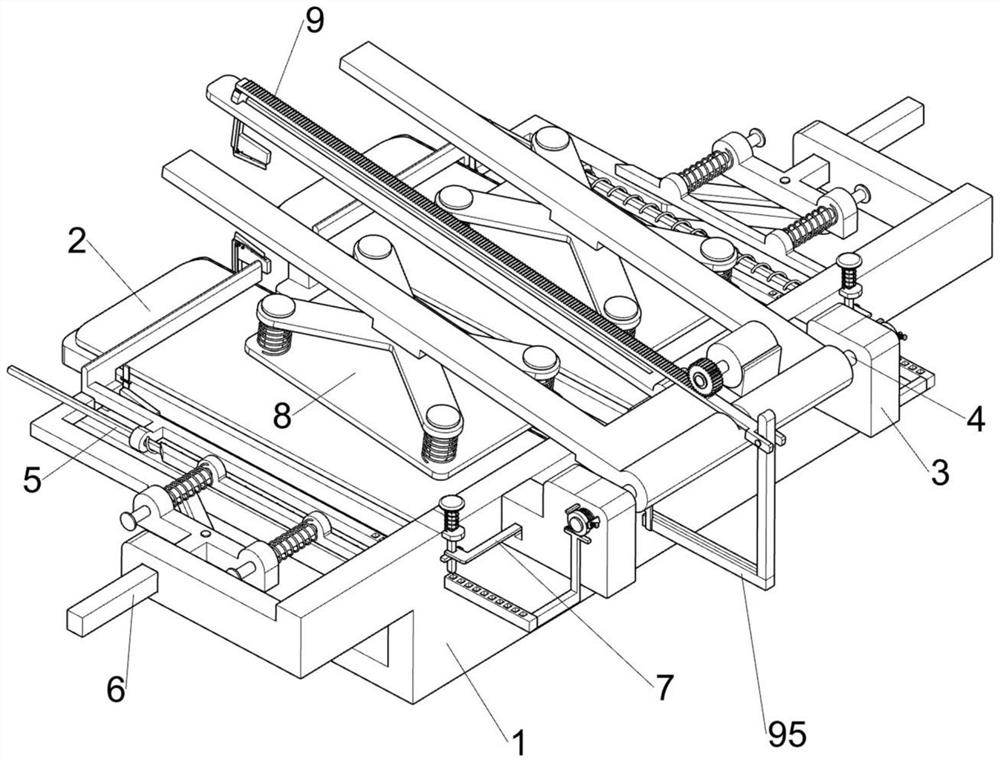

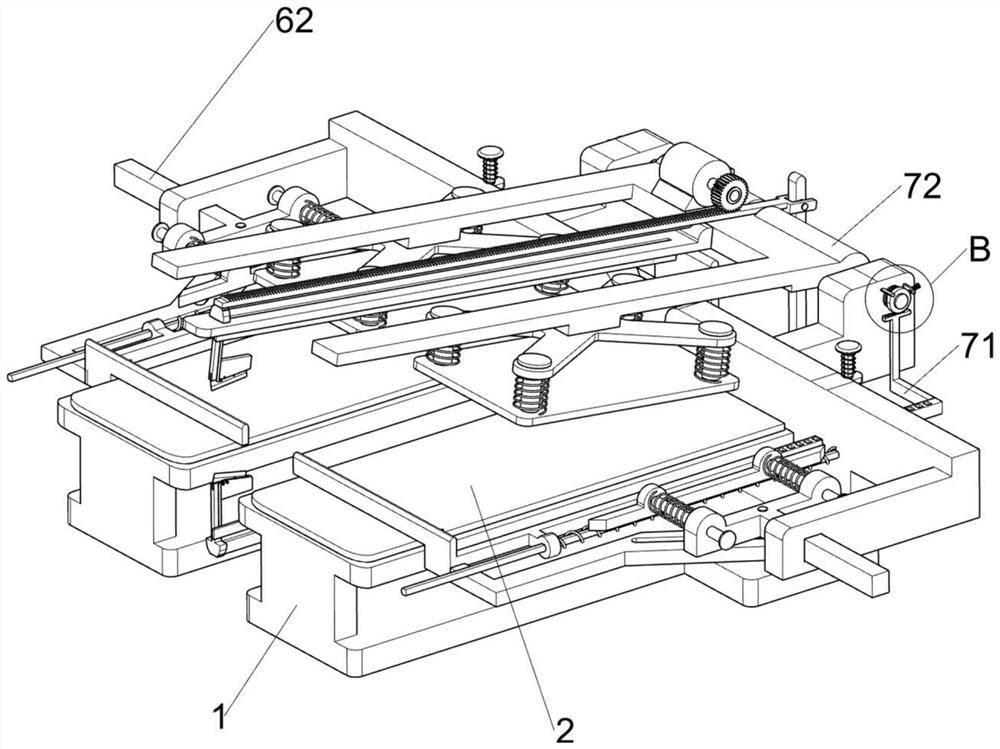

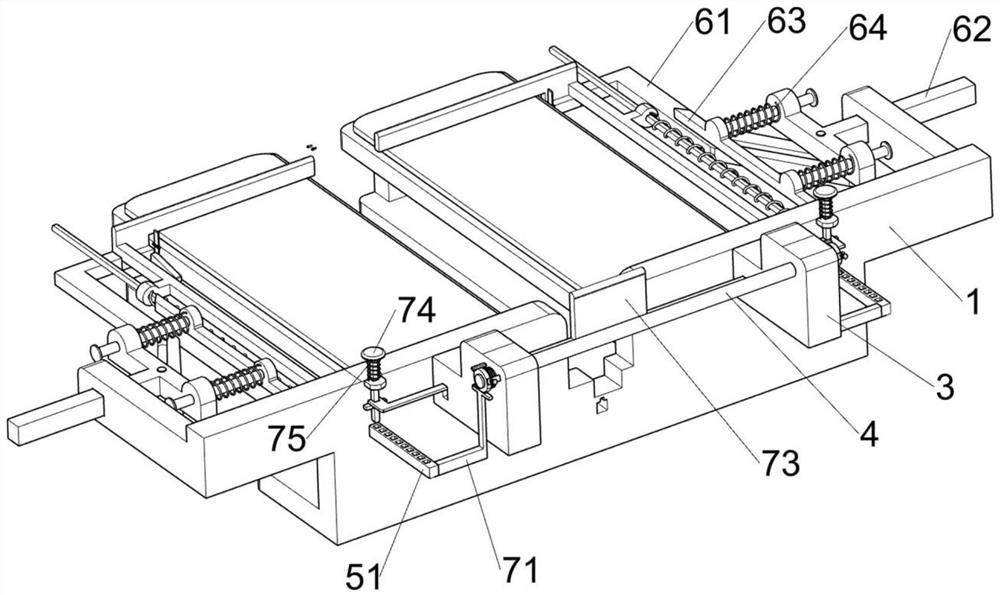

[0040] A bilateral synchronous scribing device for glass processing, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, it includes a base 1, a sponge gasket 2, a fixed seat 3, a center rod 4, a length limiting component 5, a width limiting component 6, a locking component 7, a top pressing component 8 and a scribing component 9, the top of the base 1 There are two sponge pads 2, and the suede glass can be placed on the sponge pad 2. Two fixed seats 3 are fixed on the right part of the base 1, and a central rod 4 is jointly rotatably connected between the fixed seats 3. The base 1 There is a length limiting component 5 on it, the length limiting component 5 is used to limit the matte glass of different lengths, the base 1 is provided with a width limiting component 6 and is connected with the length limiting component 5, and the width limiting co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com