Novel solid wood bending performing machine

A preforming machine and solid wood technology, applied in the direction of wood bending, wood processing equipment, heat storage heaters, etc., can solve the problems of easy coking of heat transfer oil, non-circulation of heat transfer oil, damage to the heating liner, etc., and achieve fast heating speed and high efficiency. Pass rate, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

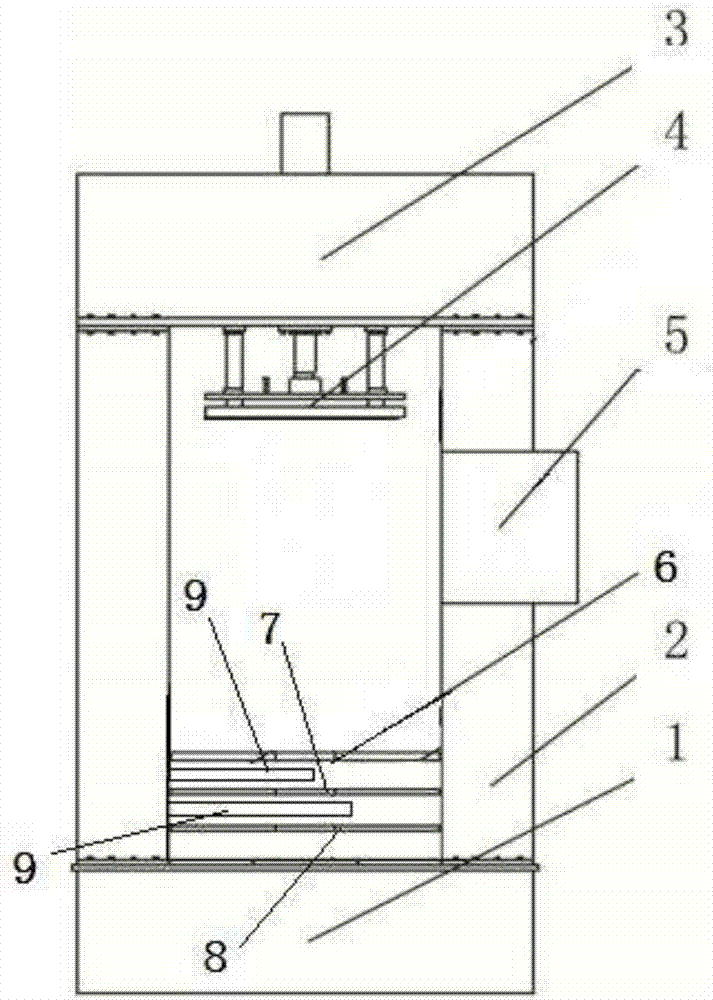

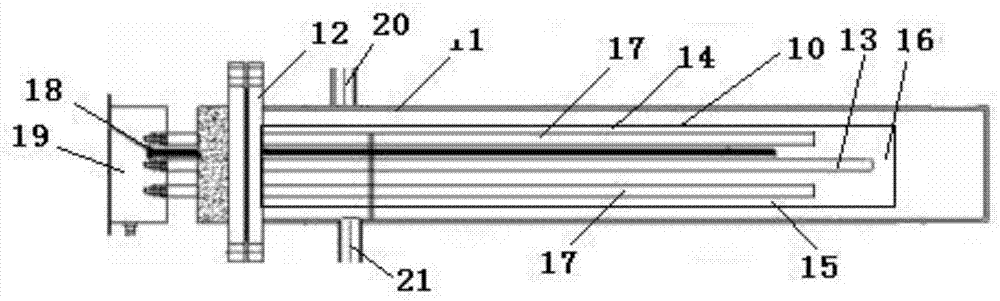

[0022] A new type of solid wood bending preforming machine, comprising a base and a main frame, the base is provided with a main frame, the top of the main frame is provided with a driving device, the driving device is connected with a PLC controller, and the PLC controls The device is arranged on the main frame, the driving device is connected with the lower pressing plate, and the base is provided with a solid wood shaping mechanism corresponding to the lower pressing plate, and the solid wood shaping mechanism includes an upper mold, a middle mold, and a lower mold. The upper mold, the middle mold, and the lower mold are arranged sequentially from top to bottom, and a thermal oil heater is arranged between the upper mold, the middle mold, and the lower mold, and the thermal oil heater includes Heating tank, oil storage tank, heating element, one side of the oil storage tank is provided with a heating element, the heating tank is provided in the oil storage tank, a partition ...

Embodiment 2

[0024] A new type of solid wood bending preforming machine, comprising a base and a main frame, the base is provided with a main frame, the top of the main frame is provided with a driving device, the driving device is connected with a PLC controller, and the PLC controls The device is arranged on the main frame, the driving device is connected with the lower pressing plate, and the base is provided with a solid wood shaping mechanism corresponding to the lower pressing plate, and the solid wood shaping mechanism includes an upper mold, a middle mold, and a lower mold. The upper mold, the middle mold, and the lower mold are arranged sequentially from top to bottom, and a thermal oil heater is arranged between the upper mold, the middle mold, and the lower mold, and the thermal oil heater includes Heating tank, oil storage tank, heating element, one side of the oil storage tank is provided with a heating element, the heating tank is provided in the oil storage tank, a partition ...

Embodiment 3

[0026] A new type of solid wood bending preforming machine, comprising a base and a main frame, the base is provided with a main frame, the top of the main frame is provided with a driving device, the driving device is connected with a PLC controller, and the PLC controls The device is arranged on the main frame, the driving device is connected with the lower pressing plate, and the base is provided with a solid wood shaping mechanism corresponding to the lower pressing plate, and the solid wood shaping mechanism includes an upper mold, a middle mold, and a lower mold. The upper mold, the middle mold, and the lower mold are arranged sequentially from top to bottom, and a thermal oil heater is arranged between the upper mold, the middle mold, and the lower mold, and the thermal oil heater includes Heating tank, oil storage tank, heating element, one side of the oil storage tank is provided with a heating element, the heating tank is provided in the oil storage tank, a partition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com