Multidirectional shockproof 3D printing helmet energy absorption buffer layer

A 3D printing and buffer layer technology, applied in the field of 3D printing helmet energy-absorbing buffer layer, to reduce vertical impact damage, delay action time, and reduce vertical impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

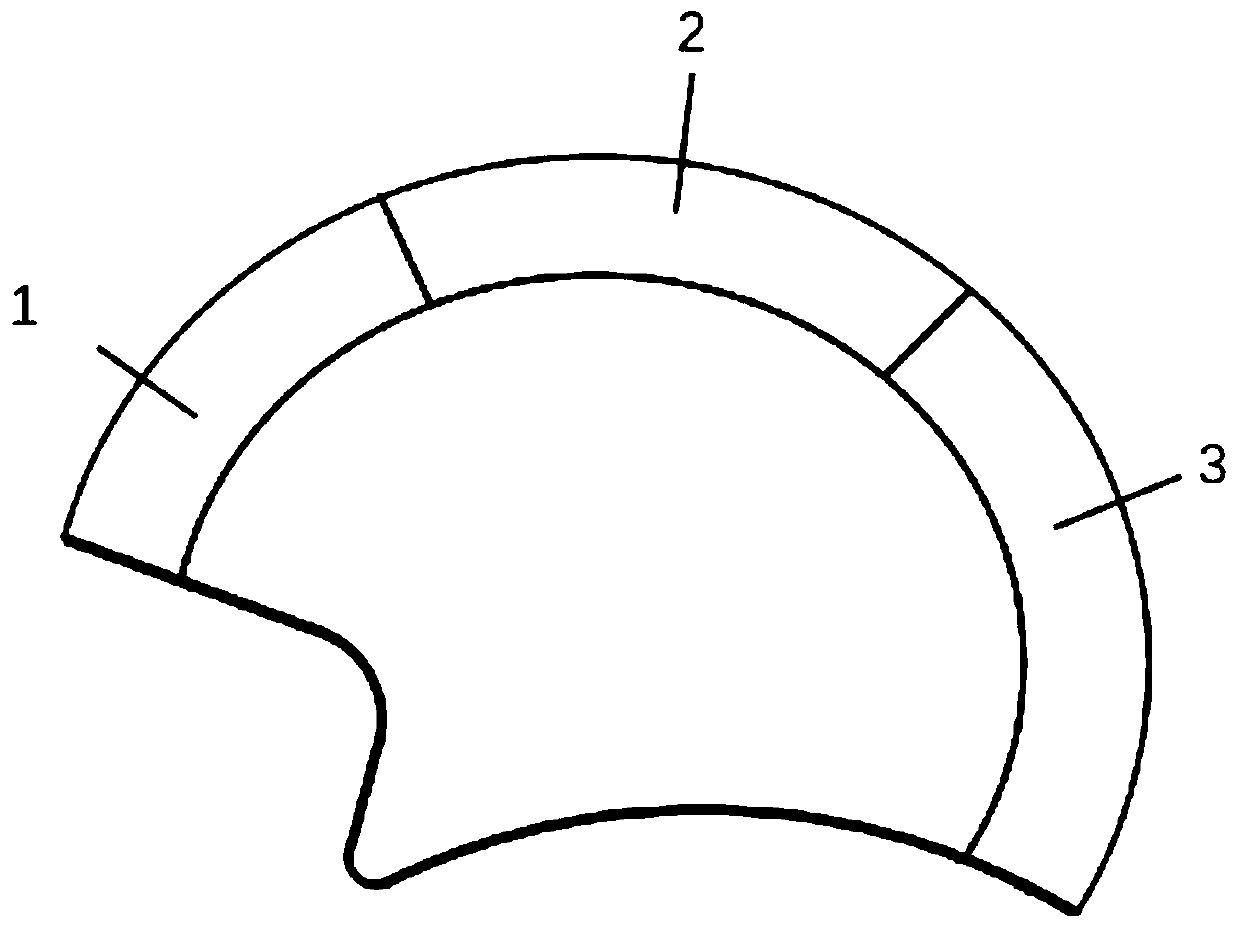

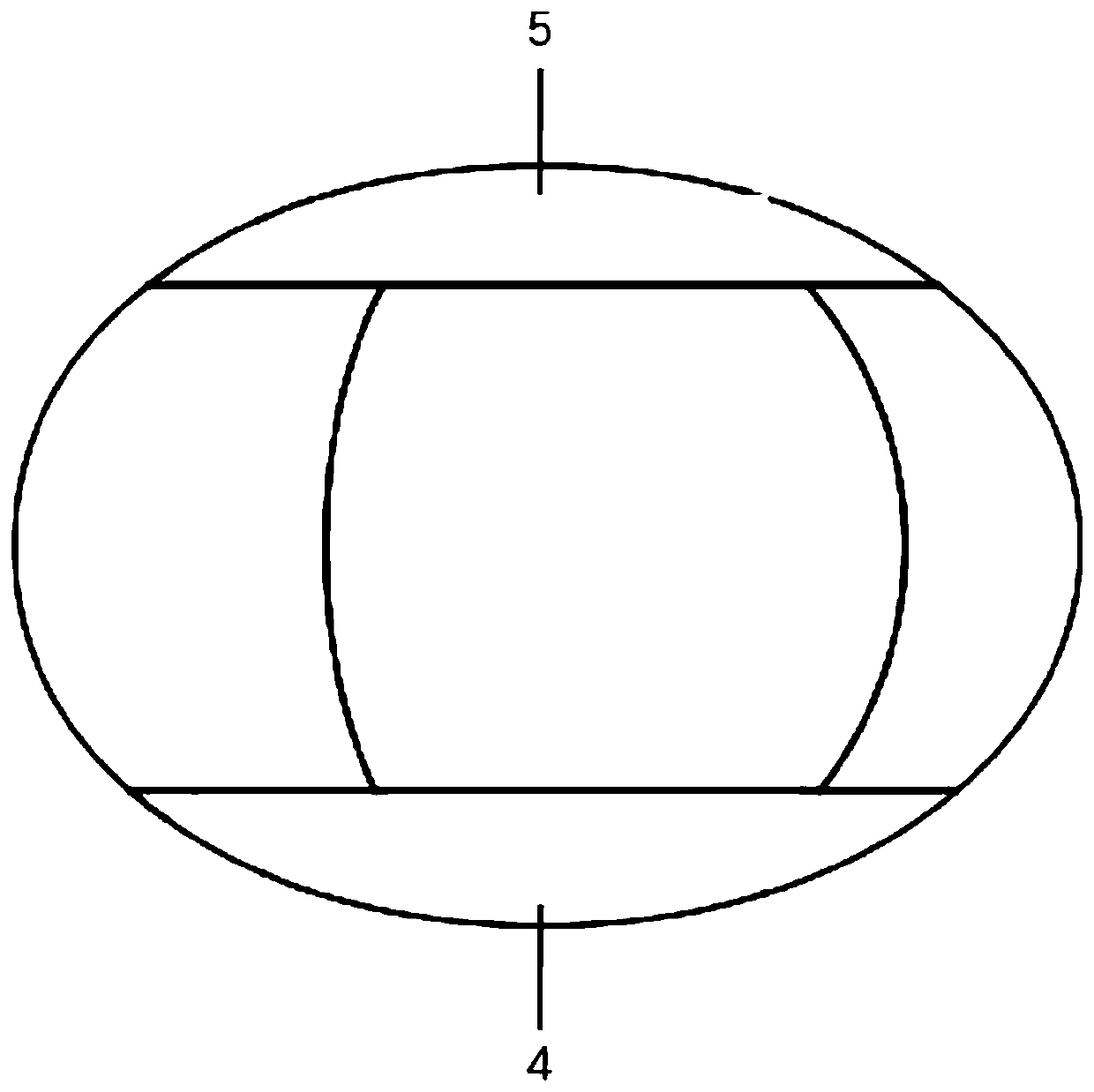

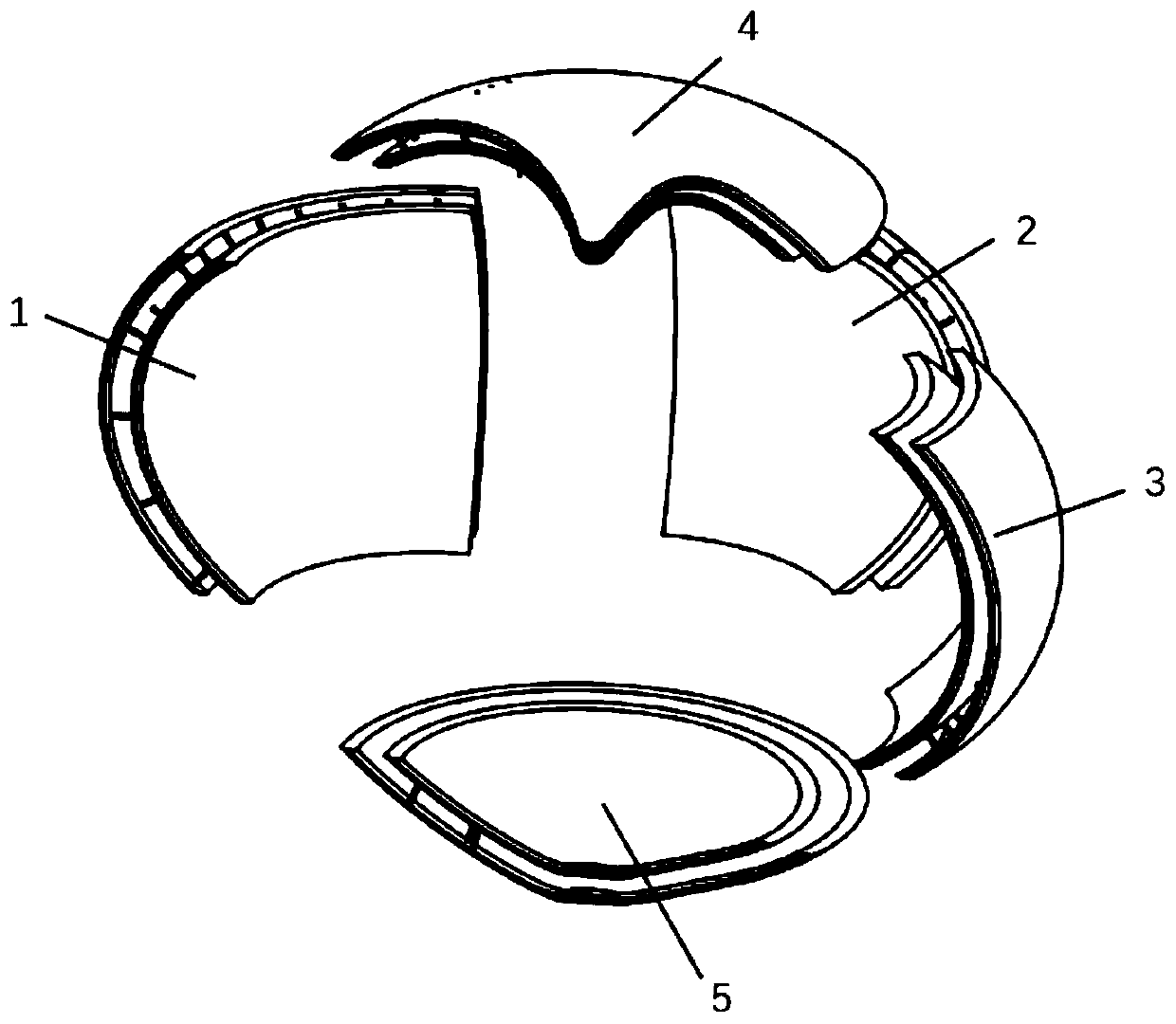

[0022] Such as Figure 1-7 Shown: a multi-directional shockproof 3D printed helmet energy-absorbing buffer layer, the 3D printed helmet energy-absorbing buffer layer is fixed on the inner side of the helmet shell;

[0023] The energy-absorbing cushioning layer of the 3D printed helmet is in the shape of a head as a whole, and consists of five split parts: a front split part 1, a rear split part 3, a left split part 4, a right split part 5 and an upper split part 2 put together;

[0024] The five slice parts all include an upper unit 6, a lower unit 7, a through hole 9 and several through rods 8, and the slice parts pass through the through rod holes 9 on the upper unit 6 and the lower unit 7 through the through rods 8 connected;

[0025] The opening cross-sectional area of the through-rod hole 9 is larger than the cross-sectional area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com